Darrencambs

Well-known member

- Joined

- Nov 14, 2010

- Messages

- 76

- Reaction score

- 0

OK, here's a few pics I took yesterday whilst stripping out the interior. More on Flickr if you want to have a look at the whole lot.

Interior looks OK from a distance:

I do have a few concerns about how close the cupboards are to the hob :shock:

Home made drawer

Slide-out bed. Frame made from Garden Decking

Underside of bed.. bit flimsy, so a bit of 'Rock n Roll' on this could be dangerous!

on this could be dangerous!

Wonky water heater and the cupboard for the gas bottle

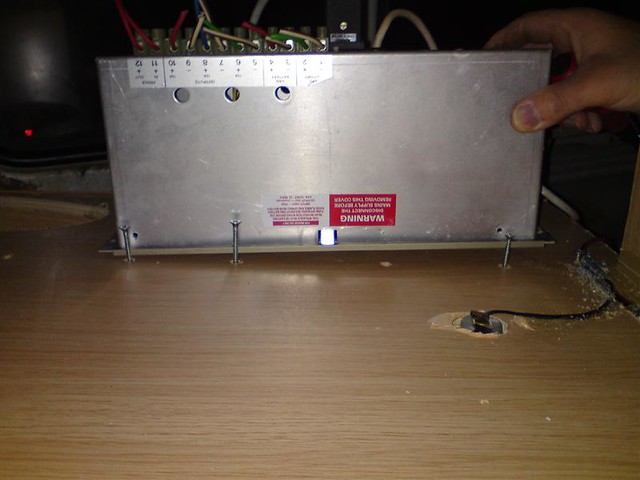

Wires and gas feed to fridge and hob - not actually connected to the hob, so I'm glad I didn't just connect up the bottle!

Drawer runner

Back of the fridge looking very rusty (anyone know what's running through that coil - butane or CFC refrigerant? Got a feeling the tube could well be porous with so much rust)

Lots of this Plastic/Polystyrene sandwich board inside the bus. Previous owner manufatured and installed conservatories for a living, so I guess he could get it cheap!

This is the hole the water heater was fitted through :roll:

Reinforcing webs have been hacked through... Think I'll close this hole up and graft the webs back in as I've got a feeling that water heater is likely to go bang or poison us with CO.

Metal plates in both rear corners - from what I can see, not actually welded but stuck on with resin and sikaflex.

Crap all over the floor when I lifted the floor boards...

... and glass everywhere. I think he must have smashed a few windows getting them out, but didn't bother to sweep up!

All in all, the floors don't look too bad - need some repairs around the rear arches and the front bulkheads but now the bus is stripped I can get on with the welding without worrying about setting something alight. There is some wax on the panels, but it looks like it's been thrown on by the handful so it's not in the seams and should be easy enough to scrape off.

The workmanship on the homemade interior is shocking to be honest, and I'm not keen on using the fridge, cooker, water heater, etc. May just scrap the lot and run the bus for a season with just a blow-up mattress and a portable stove. Focus for now is getting the chassis and shell sound and roadworthy.

Interior looks OK from a distance:

I do have a few concerns about how close the cupboards are to the hob :shock:

Home made drawer

Slide-out bed. Frame made from Garden Decking

Underside of bed.. bit flimsy, so a bit of 'Rock n Roll'

Wonky water heater and the cupboard for the gas bottle

Wires and gas feed to fridge and hob - not actually connected to the hob, so I'm glad I didn't just connect up the bottle!

Drawer runner

Back of the fridge looking very rusty (anyone know what's running through that coil - butane or CFC refrigerant? Got a feeling the tube could well be porous with so much rust)

Lots of this Plastic/Polystyrene sandwich board inside the bus. Previous owner manufatured and installed conservatories for a living, so I guess he could get it cheap!

This is the hole the water heater was fitted through :roll:

Reinforcing webs have been hacked through... Think I'll close this hole up and graft the webs back in as I've got a feeling that water heater is likely to go bang or poison us with CO.

Metal plates in both rear corners - from what I can see, not actually welded but stuck on with resin and sikaflex.

Crap all over the floor when I lifted the floor boards...

... and glass everywhere. I think he must have smashed a few windows getting them out, but didn't bother to sweep up!

All in all, the floors don't look too bad - need some repairs around the rear arches and the front bulkheads but now the bus is stripped I can get on with the welding without worrying about setting something alight. There is some wax on the panels, but it looks like it's been thrown on by the handful so it's not in the seams and should be easy enough to scrape off.

The workmanship on the homemade interior is shocking to be honest, and I'm not keen on using the fridge, cooker, water heater, etc. May just scrap the lot and run the bus for a season with just a blow-up mattress and a portable stove. Focus for now is getting the chassis and shell sound and roadworthy.