cunning plan

Well-known member

- Joined

- Jul 15, 2008

- Messages

- 2,625

- Reaction score

- 1

- Location

- Northamptonshire

- Year of Your Van(s)

- 1968

- Van Type

- Clipper / Microbus

Another question for the fantastic EaryBay techies.  opcorn:

opcorn:

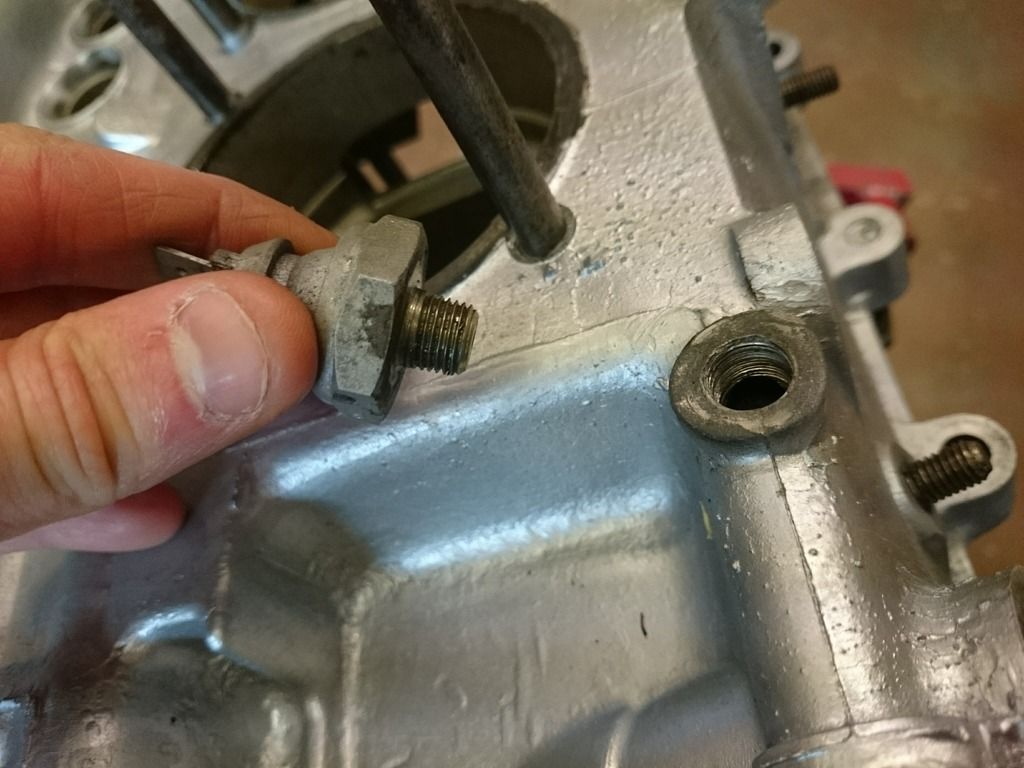

So I was cleaning the oil galleries, including the oil pressure relief valves in preparation to start rebuilding the engine. However, I noticed that when I went to put the oil pressure sensor back in, the thread at the top of the hole was massive:

The sensor will lift in and out without resistance this far:

Only here will a thread start to 'catch' ready for tightening:

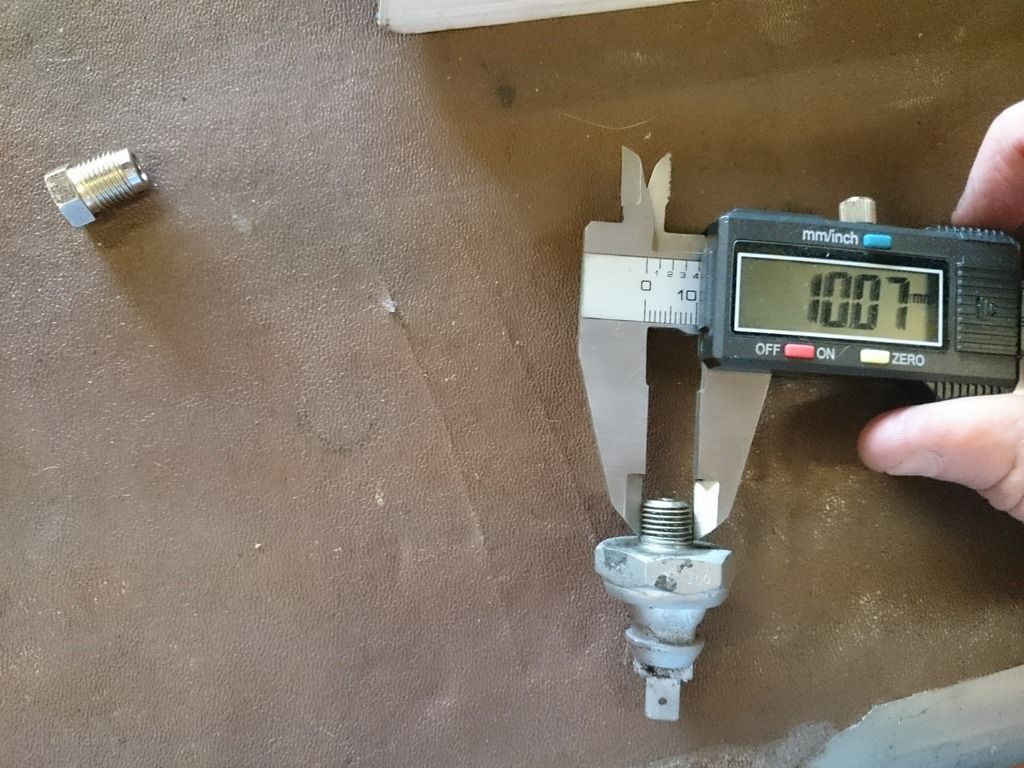

As I was measuring to try and get an idea what was going on, I noticed that the pressure sender seems to have a 'taper' to the thread.

Here it is 9.87 at the bottom of the thread:

And 10.07 at the top of the thread:

Is this correct? Is the oil pressure sender thread supposed to be tapered?

:sign0009:

So I was cleaning the oil galleries, including the oil pressure relief valves in preparation to start rebuilding the engine. However, I noticed that when I went to put the oil pressure sensor back in, the thread at the top of the hole was massive:

The sensor will lift in and out without resistance this far:

Only here will a thread start to 'catch' ready for tightening:

As I was measuring to try and get an idea what was going on, I noticed that the pressure sender seems to have a 'taper' to the thread.

Here it is 9.87 at the bottom of the thread:

And 10.07 at the top of the thread:

Is this correct? Is the oil pressure sender thread supposed to be tapered?

:sign0009: