OK so I have almost finished the re-wire on my bus. One of the main reasons for doing the re-wire was because of a very scary moment one night. I was driving along a country road and switched the headlights from dipped to main beam, no problems. About 10 seconds later as I entered a really twisty section my main beam headlights switch off on their own. I tried flicking back to dipped… nothing. Next, I went into panic mode, the sudden change in light levels meant I was struggling to see in the dark. I then tried the hazards, not the best answer but it worked, I then switched the headlight switch to side-lights and then back to main beam, still nothing I then flicked the lights back to dipped and everything came good.

Without doubt a 5p/ 50p moment! It couldn't have happened at a worse time, luckily I knew the road.

So after checking all the wiring and connectors, changing the relay and then the indicator stalk I still had problems. I ended up re-doing the entire loom, mostly for other reasons but I never really got to the bottom of the issue… until now.

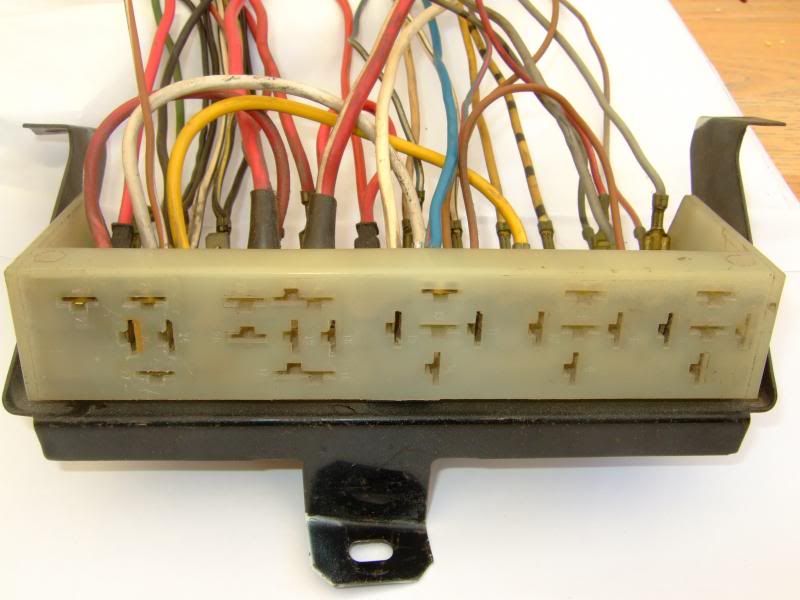

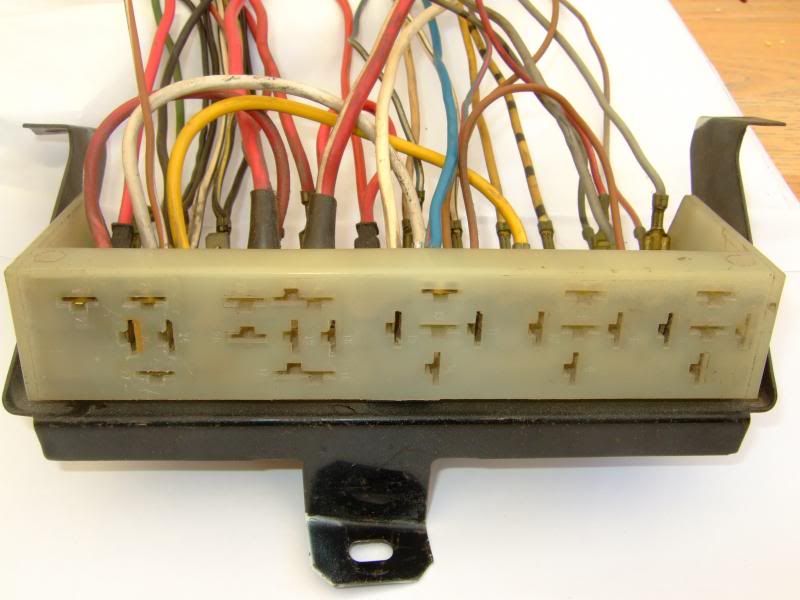

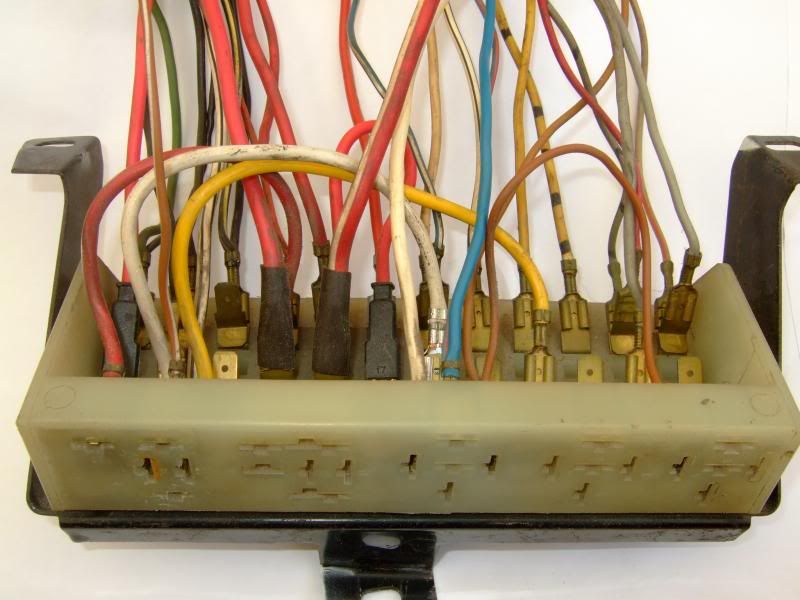

I just sold the original fuse box with wiring still attached and it was whilst looking at this I think I may have found the problem. Being a complete sado I took some pictures before I sent it off and as I straightened out the cables one came off it's fuse connector way too easily. Which one, the ****** main beam!

For the record my bus is a Euro/UK RHD '71, but I'm fairly sure other would be similar.

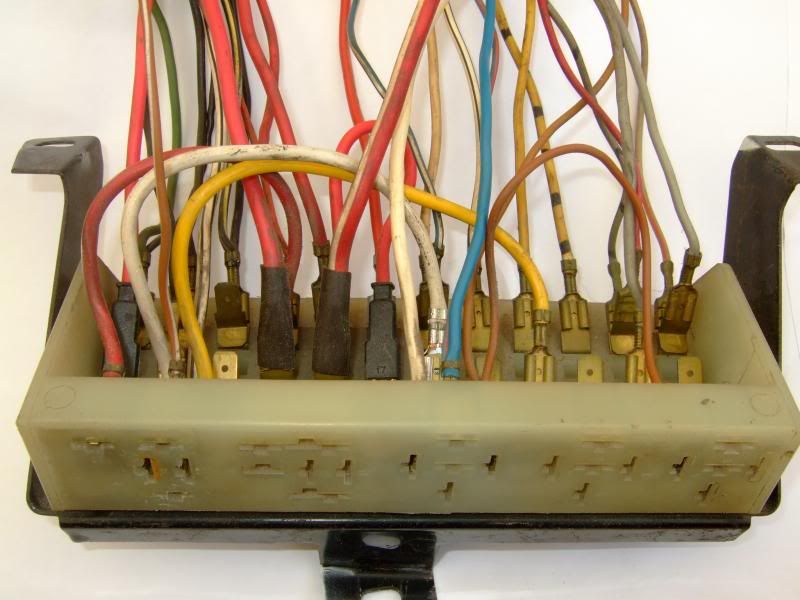

The headlight relay is situated on the left most position. It feeds two separate circuits, one with a yellow cable (dipped) and the other white (main beam).

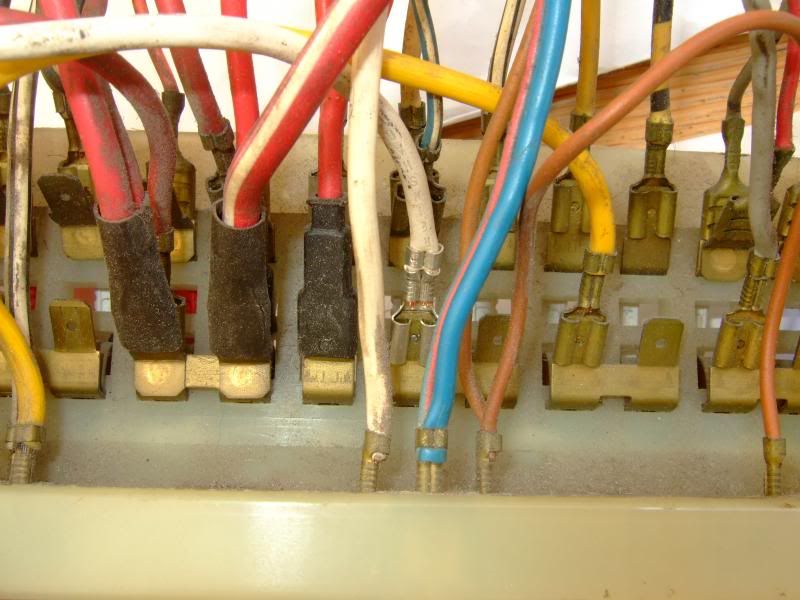

The silver connector is new and is what I replaced the original with.

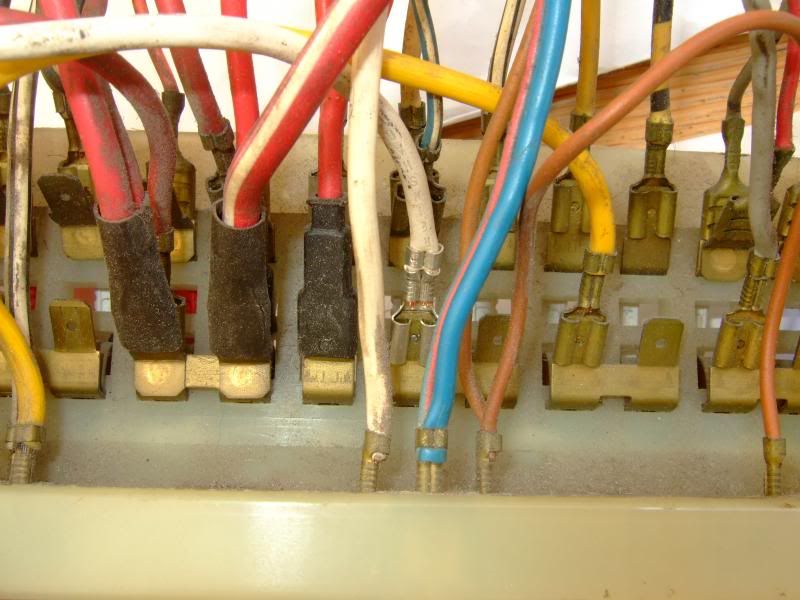

I cut the offender off but wanted to share what I found. Looks fine at a glance, except there is a small hairline crack. Under the awkward positioning of the fuse box in crappy light and pushing a mutli-meter onto the terminal gave me very false information. My pushing on the terminal made sure there was a connection.

As soon as I stopped interfering the problems all came back. It didn't take much to do this to the terminal.

It was only after me squeezing the spade with a pair of pliers and then reattaching did I realise something was wrong. Even though I had made sure it was harder to push back on, it actually turned out easier than before, it was then that I noticed the crack, bastard.

I can't tell you how long it's taken me to suss this out. It's also cost me a lot of money in the process.

To conclude I would say this to everyone, CHECK YOUR WIRING. Then CHECK IT AGAIN. Don't end up on a country road like I did and S**t yourself. I had my very young niece and nephew with me as well, talk about heart stopping!

Without doubt a 5p/ 50p moment! It couldn't have happened at a worse time, luckily I knew the road.

So after checking all the wiring and connectors, changing the relay and then the indicator stalk I still had problems. I ended up re-doing the entire loom, mostly for other reasons but I never really got to the bottom of the issue… until now.

I just sold the original fuse box with wiring still attached and it was whilst looking at this I think I may have found the problem. Being a complete sado I took some pictures before I sent it off and as I straightened out the cables one came off it's fuse connector way too easily. Which one, the ****** main beam!

For the record my bus is a Euro/UK RHD '71, but I'm fairly sure other would be similar.

The headlight relay is situated on the left most position. It feeds two separate circuits, one with a yellow cable (dipped) and the other white (main beam).

The silver connector is new and is what I replaced the original with.

I cut the offender off but wanted to share what I found. Looks fine at a glance, except there is a small hairline crack. Under the awkward positioning of the fuse box in crappy light and pushing a mutli-meter onto the terminal gave me very false information. My pushing on the terminal made sure there was a connection.

As soon as I stopped interfering the problems all came back. It didn't take much to do this to the terminal.

It was only after me squeezing the spade with a pair of pliers and then reattaching did I realise something was wrong. Even though I had made sure it was harder to push back on, it actually turned out easier than before, it was then that I noticed the crack, bastard.

I can't tell you how long it's taken me to suss this out. It's also cost me a lot of money in the process.

To conclude I would say this to everyone, CHECK YOUR WIRING. Then CHECK IT AGAIN. Don't end up on a country road like I did and S**t yourself. I had my very young niece and nephew with me as well, talk about heart stopping!