Day 4

February 19

Cheers guys, bit of an up and down day today. Finally got the roof skin separated from the frame, triple check all the spot welds are out and it will come off easy, don't force it! The front crossmember is glued particularly strongly, so I slid a flat plastering trowel down in between the gap to separate it without damaging the skin. I didn't really know what to do with the front edge, so I cut through the pillars in order to keep the windscreen seam intact, time will tell if this was a mistake...

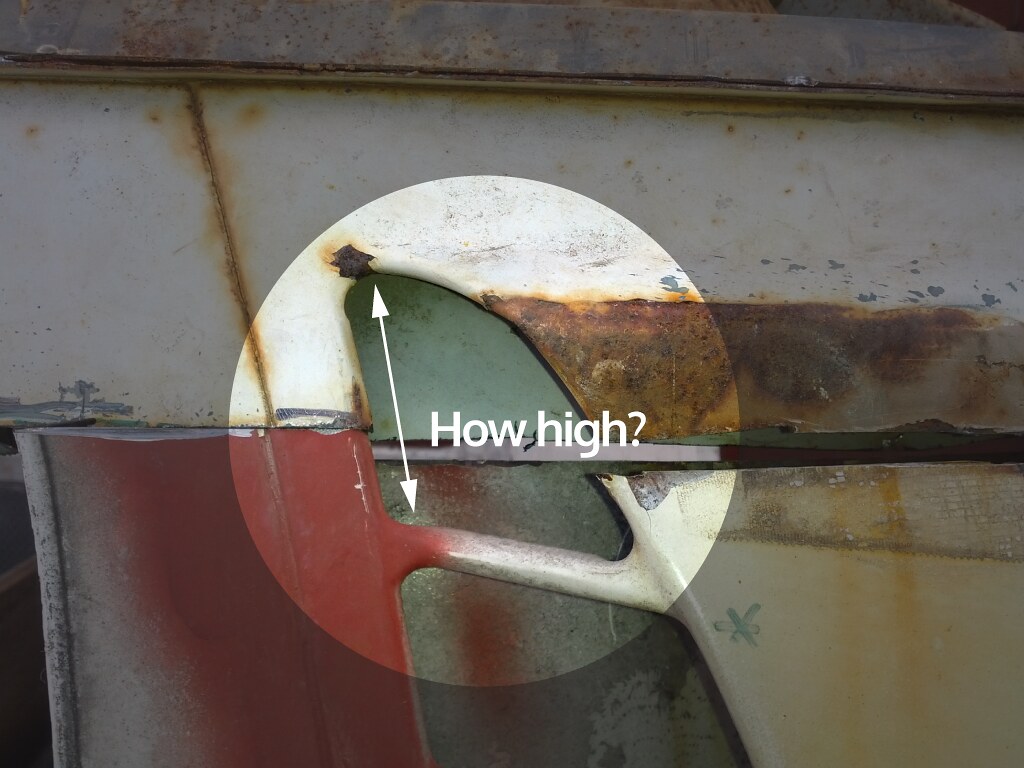

I then spent a few hours cutting away the rust from the bus gutters. My plan was to use the new frame to repair the frame on my bus, then weld the skin back on. I have decided to use the upper box section and cross members of the new frame, cutting off the lower box section and pillar remnants. I'll repair the bus lower box section to be sure it is solid and can be welded to. I'll upload some more pictures tomorrow during daylight hours.

If you look at this image elsewhere on the forum (

http://forum.earlybay.com/viewtopic.php?f=4&t=38489 ) that I modified:

The upper box section is the green and blue lines, this will come from the new frame. The lower box section is the yellow and pink lines, this will be repaired on my bus, then the two will be seam welded together.

The benefits of this method are that I do not have to cut into the pillars, meaning a lot less measuring and nervousness. Also, I can keep the frame as a single unit, rather than chopping bits off to repair the current sections jigsaw fashion. If I can get the lower box section perfectly flat and level and strong, I'm confident this will work out well! Then of course, I will simply be refitting the skin back to the original frame, so I can line up the spotwelds to ensure it's in the right position. Any thoughts welcome...