Hello folks,

So I had a bit of a mare when I went to refit my engine at the weekend, and found that something is wrong with the alignment! Prior to the engine removal, all was well, but I had noticed that the moustache bar rubbers were looking a bit perished. The engine is a Type 1 TP, and is mated to a 091 6-rib gearbox. The problem I have is that the overall length of engine and gearbox appear to be about 20mm longer than standard, and some internet research seems to give the same opinion. However, the jury seems to be out on where this extra length comes from. As I say, this was all in the van and running previously, but it appears as though the additional forces placed on the moustache bar rubbers have caused them to distort and start to split, so I'm keen to regain the natural alignment of the new ones.

I posted this on FB yesterday, and the majority of responses suggest that swapping the bell housing to a 002 will sort the issue as it is shallower, but everything else I've read suggests that the bell housings are near enough the same depth, it is just the starter sits further out in the 091; and actually the extra length is in the gear set section. Does anyone have a 002 gearbox lying around that could measure each of the case sections (to the mating faces) to compare with mine?

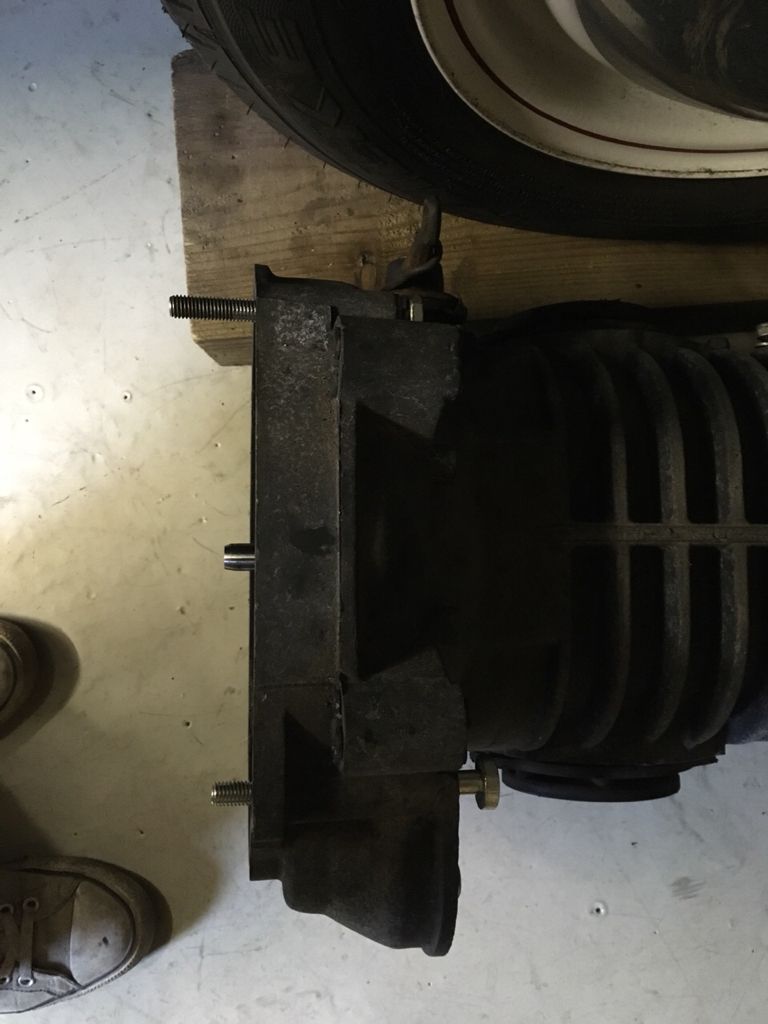

I gleaned some information regarding the differences in the starter mounting location - on a 002, the bell housing face to the starter flange is 7.0cm, whilst a 009 is 8.5cm. Will be checking mine later to confirm which it is. As you can see in the following pictures, a standard D bolt isn’t long enough to get a nut on the end when installed, and the threaded bar and nuts was what was being used instead. I’m expecting to find this is a standard 091 bell housing:

So the obvious answer (to me!) is to slot the existing mounting holes of the front nose cone hanger, thus allowing the extra length to be taken up here, and then shortening or re-dimpling a section of the gear shift rod to prevent it from cranking too far backwards. I don't suppose 20mm of movement will be enough to cause any driveshaft / CV issues, but would appreciate anyone's input on any reason why this can't be done.

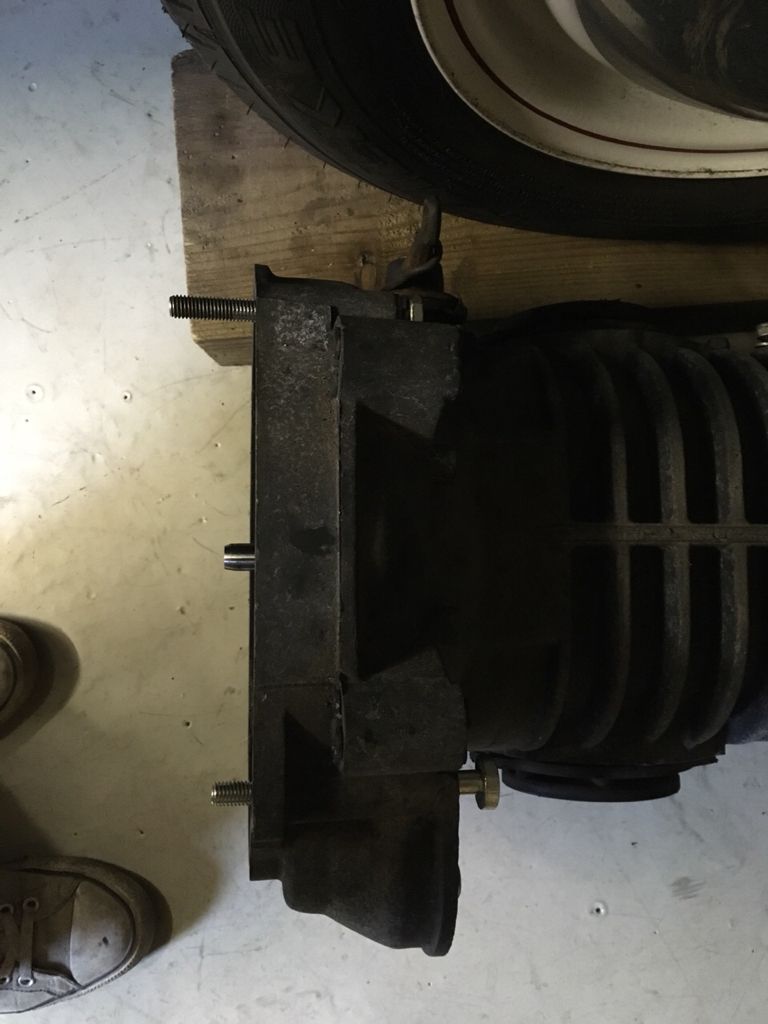

Final question, I've noticed the top stud protruding from the nose cone end is very long - so much so, that it has been touching a part of the centre of the torsion bar tube. The bottom stud has already been crudely cut shorter. This is currently stopping me from doing what I was planning to do above - shunt the gearbox forward by cutting the slots in the mount. Before I cut this off, is there any reason why this has been left long, i.e. is it supposed to limit the movement of the engine and box fore and aft? The only reason I've thought this, is because there looks to be some sort of locating boss in the centre of the torsion tube.

Advice welcomed!

Sent from my iPhone using Tapatalk

So I had a bit of a mare when I went to refit my engine at the weekend, and found that something is wrong with the alignment! Prior to the engine removal, all was well, but I had noticed that the moustache bar rubbers were looking a bit perished. The engine is a Type 1 TP, and is mated to a 091 6-rib gearbox. The problem I have is that the overall length of engine and gearbox appear to be about 20mm longer than standard, and some internet research seems to give the same opinion. However, the jury seems to be out on where this extra length comes from. As I say, this was all in the van and running previously, but it appears as though the additional forces placed on the moustache bar rubbers have caused them to distort and start to split, so I'm keen to regain the natural alignment of the new ones.

I posted this on FB yesterday, and the majority of responses suggest that swapping the bell housing to a 002 will sort the issue as it is shallower, but everything else I've read suggests that the bell housings are near enough the same depth, it is just the starter sits further out in the 091; and actually the extra length is in the gear set section. Does anyone have a 002 gearbox lying around that could measure each of the case sections (to the mating faces) to compare with mine?

I gleaned some information regarding the differences in the starter mounting location - on a 002, the bell housing face to the starter flange is 7.0cm, whilst a 009 is 8.5cm. Will be checking mine later to confirm which it is. As you can see in the following pictures, a standard D bolt isn’t long enough to get a nut on the end when installed, and the threaded bar and nuts was what was being used instead. I’m expecting to find this is a standard 091 bell housing:

So the obvious answer (to me!) is to slot the existing mounting holes of the front nose cone hanger, thus allowing the extra length to be taken up here, and then shortening or re-dimpling a section of the gear shift rod to prevent it from cranking too far backwards. I don't suppose 20mm of movement will be enough to cause any driveshaft / CV issues, but would appreciate anyone's input on any reason why this can't be done.

Final question, I've noticed the top stud protruding from the nose cone end is very long - so much so, that it has been touching a part of the centre of the torsion bar tube. The bottom stud has already been crudely cut shorter. This is currently stopping me from doing what I was planning to do above - shunt the gearbox forward by cutting the slots in the mount. Before I cut this off, is there any reason why this has been left long, i.e. is it supposed to limit the movement of the engine and box fore and aft? The only reason I've thought this, is because there looks to be some sort of locating boss in the centre of the torsion tube.

Advice welcomed!

Sent from my iPhone using Tapatalk