Haveacamper

Well-known member

- Joined

- Oct 2, 2007

- Messages

- 2,073

- Reaction score

- 5

As there have been so many people over the years expressing an interest in upgrading their brakes to Porsche brakes under the assumption it will provide incredibly better braking performance, I have recently had to work out the difference to enable me to register my recently imported camper to Australia.

As this forum has been an incredible place of support and knowledge sharing over the years I have been a member I thought that I would share with everyone my findings.

Initially, I will only deal with the front brakes – I will hopefully add the rear brakes with time.

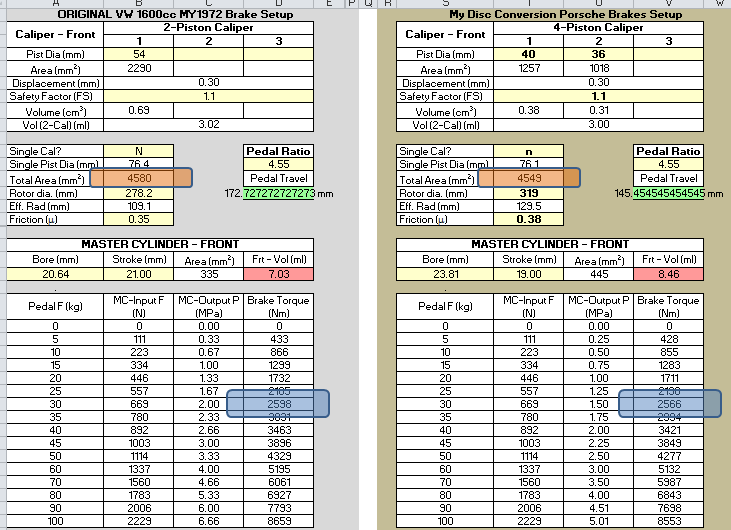

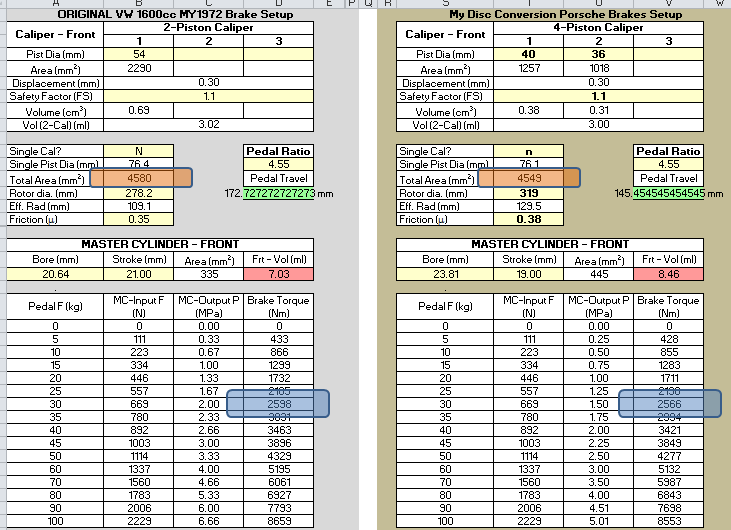

Standard setup:

Twin pot calliper with 54mm piston

Solid disc of 280mm diameter

My upgraded Porsche Boxster S setup:

Quad pot calliper with 40mm & 36mm pistons

Vented cross drilled disc 320mm diameter

Standard non-servo Master Cylinder:

Bore = 20.64mm

Front circuit stroke = 21.00mm

Rear circuit stroke = 17.00mm

Standard Servo-assisted Master Cylinder:

Bore = 23.81mm

Front circuit stroke = 19.00mm

Rear circuit stroke = 13.00mm

Quickly, you can calculate the total piston area for both standard and Porsche setup

Standard = 4580mm^2

Porsche = 4549mm ^2

So for the same brake pressure the piston force would be almost identical (Force = Pressure X Area)

By upgrading the discs (read larger disc diameter), you do increase the distance from the wheel centre that the brake force is applied. Therefore, the brake torque (Force x perpendicular distance that the force is applied (Lever arm)) increases.

So even though the piston force is almost identical for the same line pressure, the increased disc diameter will improve the brake torque.

The Master cylinder sizing essentially translates the pedal force to line pressure. The Bore x Stroke provides the overall MC volume of a single pedal depression which obviously must be greater than the total piston volume required otherwise you “stroke” the MC. The greater the Bore, the lower the line pressure for a given pedal force. Another way to look at it…if you increase the bore and want to achieve the same braking torque, you would have to depress the pedal further.

Now if we consider replacing the non-servo MC with the Servo MC we see that the bore increases in diameter and decreases slightly in the stroke. The result is that the overall volumetric capacity goes up, but as I just noted, the line pressure for the same pedal travel would go down. THIS IS NOT CONSIDERING THE BENEFIT OF WHAT THE SERVO ASSISTANCE PROVIDES!!!

AN ASIDE: When I first “upgraded” my brakes and drove the camper to the MOT station, I did not have the servo hooked up to the engine vacuum. I was considerably underwhelmed by the braking performance (even with the rear disc brake conversion). Having now done these calculations I understand why. My overall piston area is slightly lower, I had a larger bore master cylinder providing less line pressure for the same brake pedal force!!!

Servo:

Looking in the Haynes/Bentley it would appear that the servo unit provides a ratio of 2.0:1.0 assist. Implying that even though my master cylinder on its own degrades my braking performance, the gains I would achieve from the servo assistance seriously outweighs that.

What would certainly be worth considering for those who are weighing up a brake upgrade and specifically by adding a servo, is to actually fit a remote servo which allows you to maintain the stock master cylinder. This way, you maintain a smaller MC bore (i.e higher line pressure) AND a servo factor of 2:1. The “upgrade” of Porsche brakes considering the desire for better brake torque in isolation may appear to not really be worth the financials and/or effort.

I apologise if I mis-quote here, but I think it was Graham L who said to someone on here a few years ago that an individual who wished to upgrade to Porsche brakes would be better off fitting a brake servo before outlaying for the Porsche crest!

There would be no doubt that you would be able to purchase higher performance pads (read higher friction) which will further improve the brake torque being applied with the Porsche setup. Also, the larger pad area and vented disc will greatly improve brake fade and over-heating for multiple hard braking, but my guessing is that most here are more concerned with stopping distance and braking effort for a single event.

So the purpose of this thread was really just to highlight with some real life numbers that I believe people would be better off, in the first instance , adding a servo to their braking system for an initial upgrade.

Any questions then please ask and I will try to explain. I am currently trying to sort out the rear and will add this in time.

NaFe

As this forum has been an incredible place of support and knowledge sharing over the years I have been a member I thought that I would share with everyone my findings.

Initially, I will only deal with the front brakes – I will hopefully add the rear brakes with time.

Standard setup:

Twin pot calliper with 54mm piston

Solid disc of 280mm diameter

My upgraded Porsche Boxster S setup:

Quad pot calliper with 40mm & 36mm pistons

Vented cross drilled disc 320mm diameter

Standard non-servo Master Cylinder:

Bore = 20.64mm

Front circuit stroke = 21.00mm

Rear circuit stroke = 17.00mm

Standard Servo-assisted Master Cylinder:

Bore = 23.81mm

Front circuit stroke = 19.00mm

Rear circuit stroke = 13.00mm

Quickly, you can calculate the total piston area for both standard and Porsche setup

Standard = 4580mm^2

Porsche = 4549mm ^2

So for the same brake pressure the piston force would be almost identical (Force = Pressure X Area)

By upgrading the discs (read larger disc diameter), you do increase the distance from the wheel centre that the brake force is applied. Therefore, the brake torque (Force x perpendicular distance that the force is applied (Lever arm)) increases.

So even though the piston force is almost identical for the same line pressure, the increased disc diameter will improve the brake torque.

The Master cylinder sizing essentially translates the pedal force to line pressure. The Bore x Stroke provides the overall MC volume of a single pedal depression which obviously must be greater than the total piston volume required otherwise you “stroke” the MC. The greater the Bore, the lower the line pressure for a given pedal force. Another way to look at it…if you increase the bore and want to achieve the same braking torque, you would have to depress the pedal further.

Now if we consider replacing the non-servo MC with the Servo MC we see that the bore increases in diameter and decreases slightly in the stroke. The result is that the overall volumetric capacity goes up, but as I just noted, the line pressure for the same pedal travel would go down. THIS IS NOT CONSIDERING THE BENEFIT OF WHAT THE SERVO ASSISTANCE PROVIDES!!!

AN ASIDE: When I first “upgraded” my brakes and drove the camper to the MOT station, I did not have the servo hooked up to the engine vacuum. I was considerably underwhelmed by the braking performance (even with the rear disc brake conversion). Having now done these calculations I understand why. My overall piston area is slightly lower, I had a larger bore master cylinder providing less line pressure for the same brake pedal force!!!

Servo:

Looking in the Haynes/Bentley it would appear that the servo unit provides a ratio of 2.0:1.0 assist. Implying that even though my master cylinder on its own degrades my braking performance, the gains I would achieve from the servo assistance seriously outweighs that.

What would certainly be worth considering for those who are weighing up a brake upgrade and specifically by adding a servo, is to actually fit a remote servo which allows you to maintain the stock master cylinder. This way, you maintain a smaller MC bore (i.e higher line pressure) AND a servo factor of 2:1. The “upgrade” of Porsche brakes considering the desire for better brake torque in isolation may appear to not really be worth the financials and/or effort.

I apologise if I mis-quote here, but I think it was Graham L who said to someone on here a few years ago that an individual who wished to upgrade to Porsche brakes would be better off fitting a brake servo before outlaying for the Porsche crest!

There would be no doubt that you would be able to purchase higher performance pads (read higher friction) which will further improve the brake torque being applied with the Porsche setup. Also, the larger pad area and vented disc will greatly improve brake fade and over-heating for multiple hard braking, but my guessing is that most here are more concerned with stopping distance and braking effort for a single event.

So the purpose of this thread was really just to highlight with some real life numbers that I believe people would be better off, in the first instance , adding a servo to their braking system for an initial upgrade.

Any questions then please ask and I will try to explain. I am currently trying to sort out the rear and will add this in time.

NaFe