- Joined

- Sep 24, 2009

- Messages

- 1,556

- Reaction score

- 65

- Location

- Warwickshire

- Year of Your Van(s)

- 1970

- Van Type

- Microbus

Whilst on holiday in Cornwall in the summer of 2009, and after talking to my partner about family camping holidays, the decision was made to fulfil a lifelong love affair with the Volkswagen Transporter. I have always loved cars, and always loved old Volkswagens although have got to the ripe old age of 40 without ever owning one. After getting back from Cornwall the search was on, trawling eBay, buying a few magazines and brushing up on my knowledge so I at least looked like I knew what I was talking about.

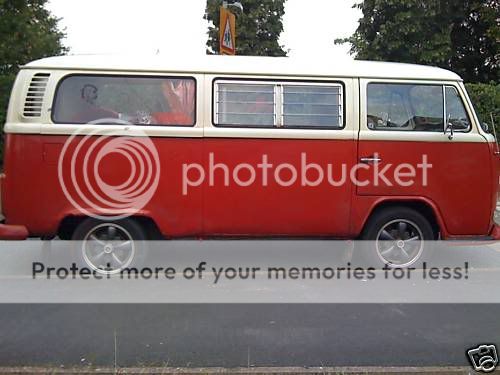

After a few close run auctions, I finally found something I couldn’t believe. I was at work and just happened to be browsing eBay, when I spotted a 72 crossover tin top. The auction had both a start price and a buy it now of the same amount £1500 (never have figured that one out). The price was too good an opportunity to miss. I was trying to contact my girlfriend to tell her and constantly refreshing the page. The auction had only been on about 6 minutes and every time I refreshed the page the number of views was increasing rapidly. I bit the bullet and hit buy it now.

The bus was only about 20 miles away from where we live which was another bonus. We went to pick her up on 19th September and this is how she stood then.

The MOT had run out in May but there didn’t look that much wrong (although I knew how good body shops can make things look nowadays). We took her out for a spin, and the money changed hands.

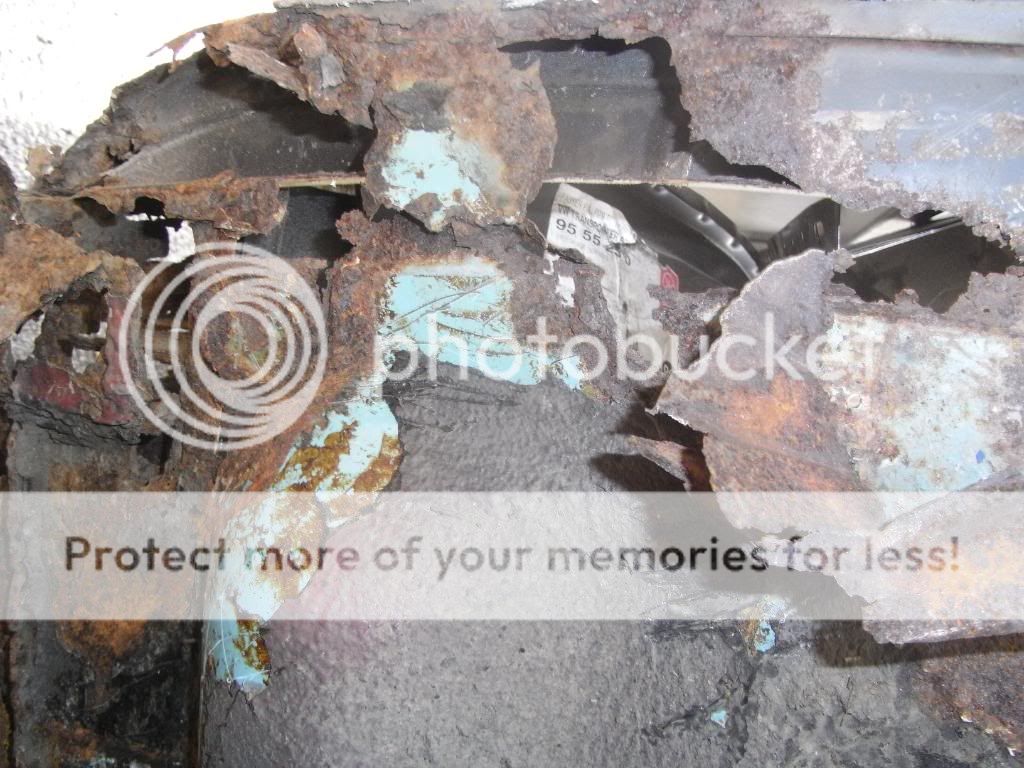

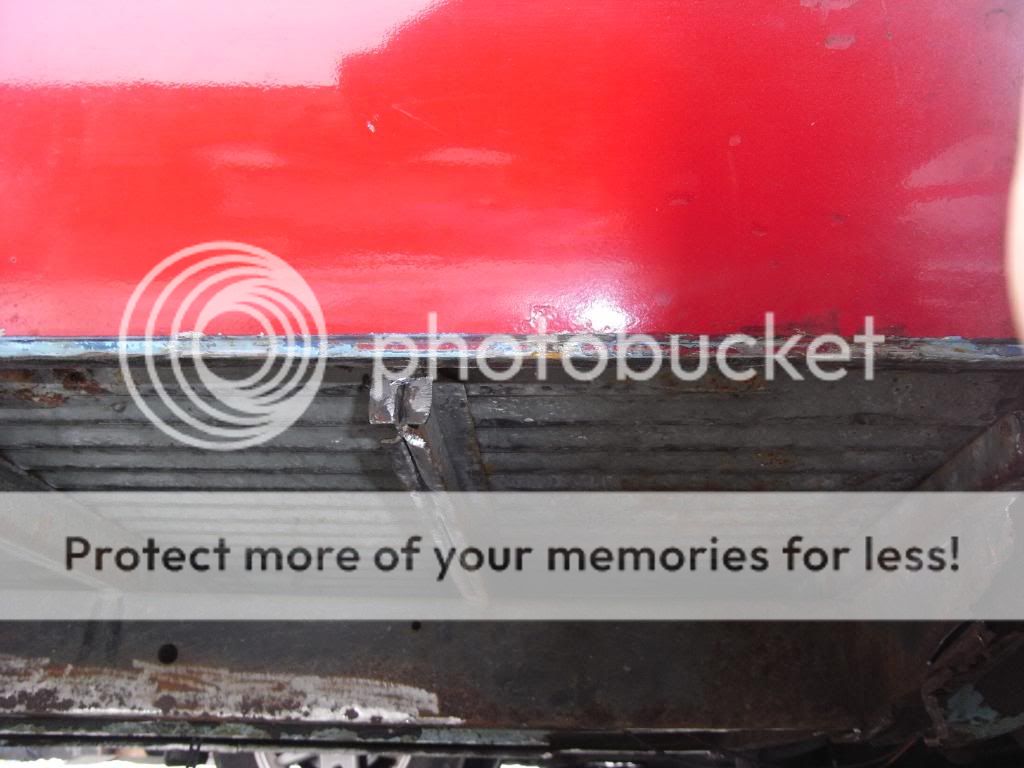

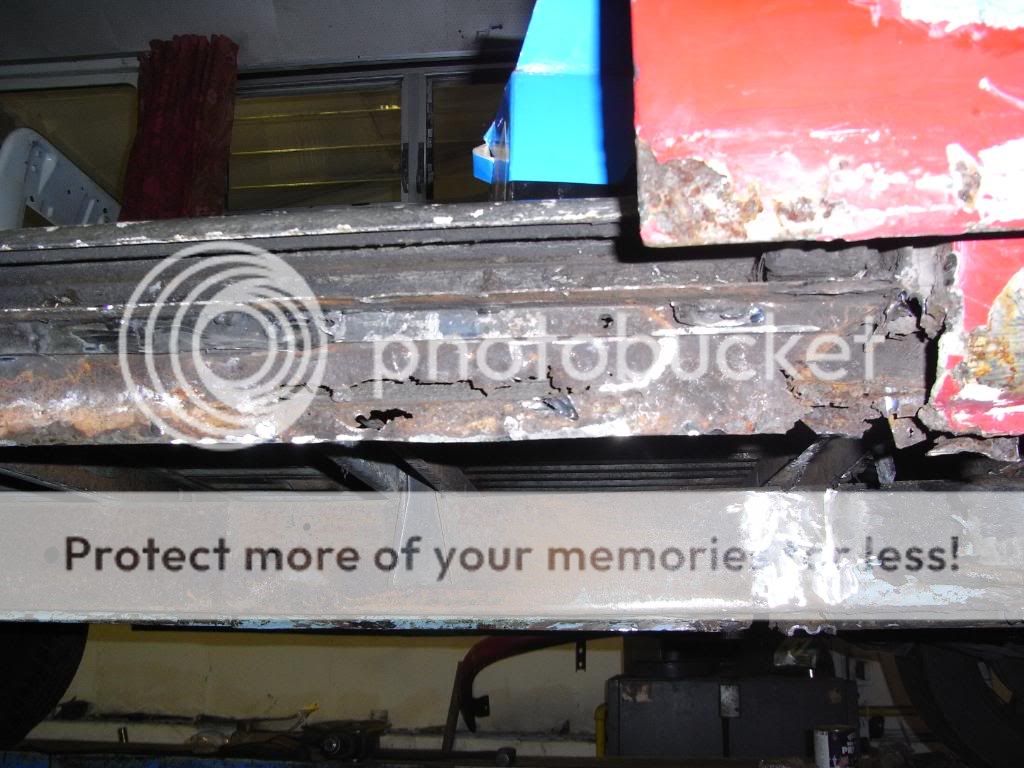

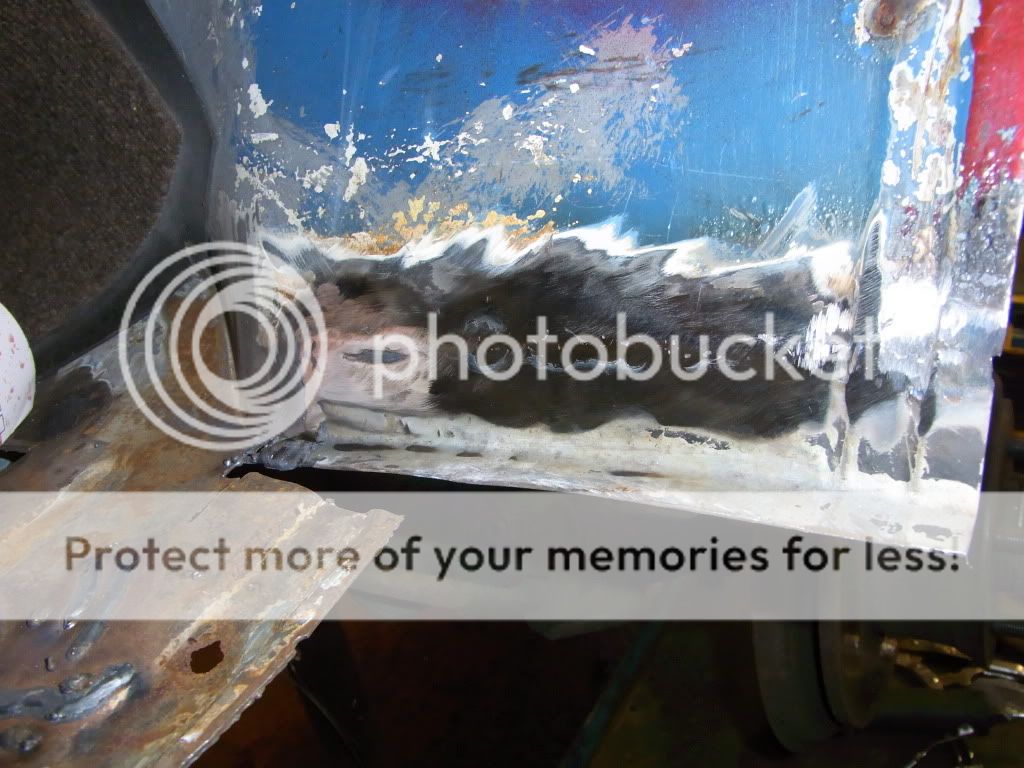

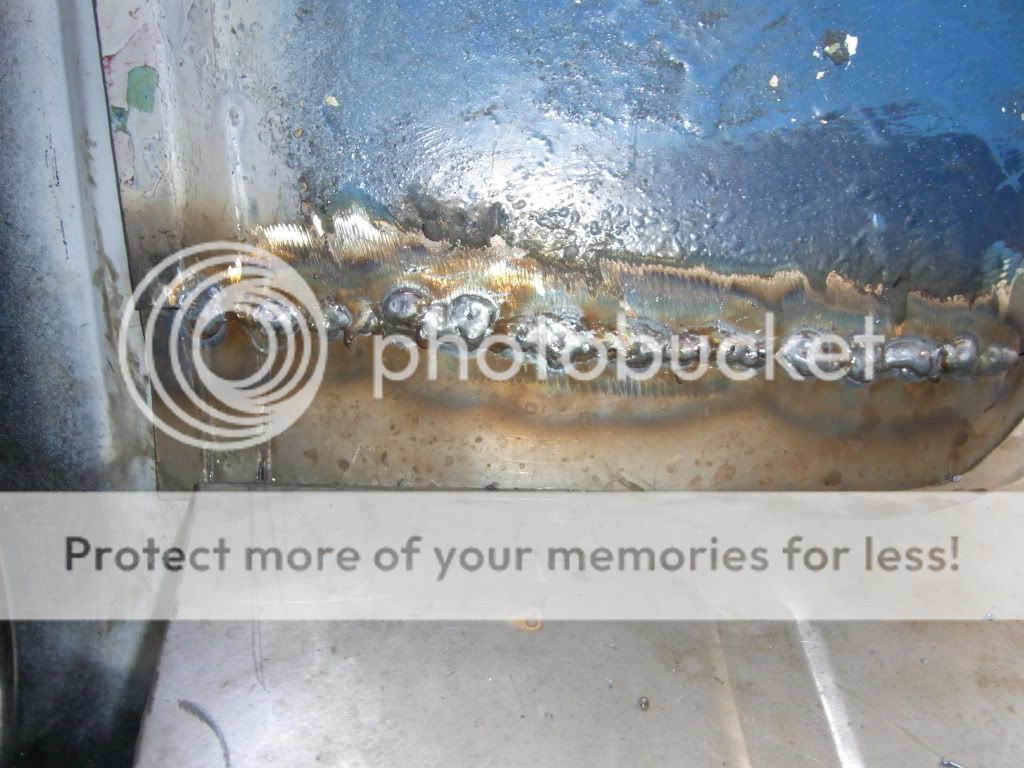

Luckily I have a friend with an MOT garage so I took her to him and got her up in the air for a good look. My mate isn’t a fan of these old things and told me any mates rates were now out the window. He also said ‘just patch it up get it MOT’d’ and ‘buy a proper camper’ if I wanted one. I never took his advice ïŠ

Buying the bus happened to coincide with the company I work for losing out on a major government contract. We were being taken over by another IT company so although strange times I found myself with time on my hands. (I ended up being at home for almost 4 months but most of it was spent catching up on household jobs).

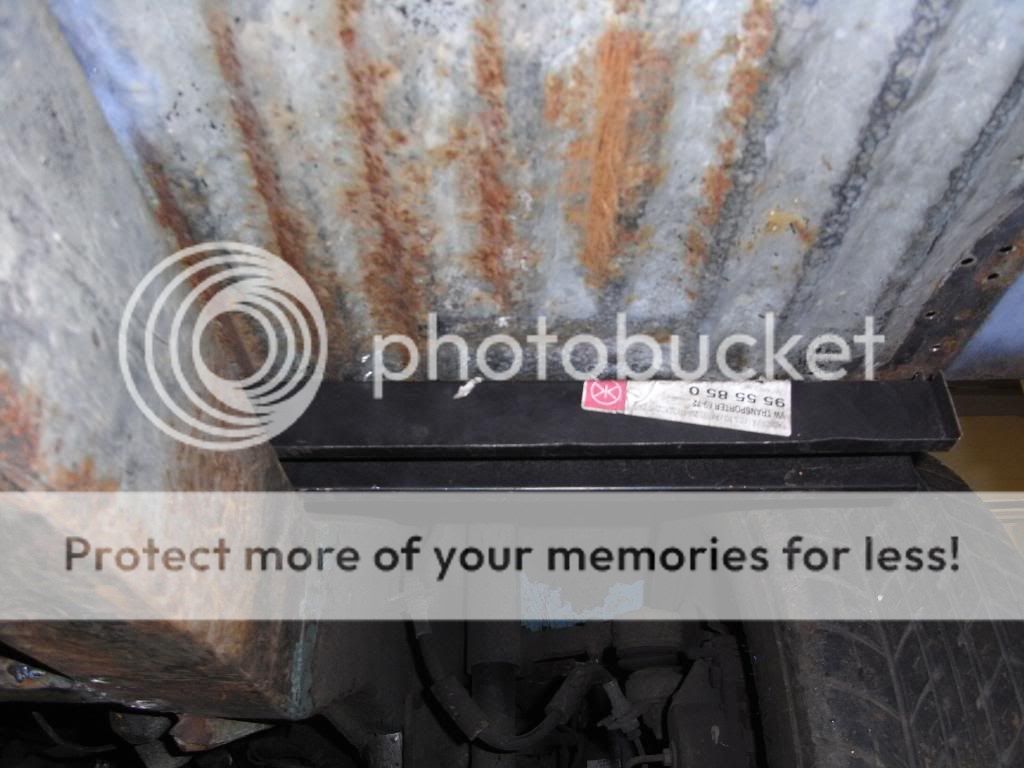

I decided that with the time I had, and having fiddled with cars regularly till my late twenties (Mk1, Mk2 Escorts, Dolly Sprints to name but a few), I would take the time and buy all the bits it needed to do a ‘proper’ job.

As I never got round to writing a rebuild thread I though it time I started.

After a few close run auctions, I finally found something I couldn’t believe. I was at work and just happened to be browsing eBay, when I spotted a 72 crossover tin top. The auction had both a start price and a buy it now of the same amount £1500 (never have figured that one out). The price was too good an opportunity to miss. I was trying to contact my girlfriend to tell her and constantly refreshing the page. The auction had only been on about 6 minutes and every time I refreshed the page the number of views was increasing rapidly. I bit the bullet and hit buy it now.

The bus was only about 20 miles away from where we live which was another bonus. We went to pick her up on 19th September and this is how she stood then.

The MOT had run out in May but there didn’t look that much wrong (although I knew how good body shops can make things look nowadays). We took her out for a spin, and the money changed hands.

Luckily I have a friend with an MOT garage so I took her to him and got her up in the air for a good look. My mate isn’t a fan of these old things and told me any mates rates were now out the window. He also said ‘just patch it up get it MOT’d’ and ‘buy a proper camper’ if I wanted one. I never took his advice ïŠ

Buying the bus happened to coincide with the company I work for losing out on a major government contract. We were being taken over by another IT company so although strange times I found myself with time on my hands. (I ended up being at home for almost 4 months but most of it was spent catching up on household jobs).

I decided that with the time I had, and having fiddled with cars regularly till my late twenties (Mk1, Mk2 Escorts, Dolly Sprints to name but a few), I would take the time and buy all the bits it needed to do a ‘proper’ job.

As I never got round to writing a rebuild thread I though it time I started.