You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which Spot weld drill bits do recommend?

- Thread starter Caboose

- Start date

Help Support Early Bay Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Fortunate Son

Well-known member

Machinemart do a set containing the solid and the "barrel" type. It is branded as Clarke but I think they all come from the same Chinese factory! Having used various expensive solid and barrel types before I was a bit dubious about buying it, but fair play it is very good quality and value

Link - http://www.machinemart.co.uk/shop/product/details/clarke-cht685-spot-weld-cutter-set" onclick="window.open(this.href);return false;

I often wish for a smaller dia drill bit though - most seem to be around 8 mm which is good for quick unpicking but sometimes I want to go around 4 or 5 mm if I will be reusing the removed panel - I have to then use a standard 4 mm drill bit and hit the centre bang on with the centre punch first and then drill really carefully. It depends on how well looked after the tips of the spot welder were in the factory!!

Not that you asked but I am having a lot of success splitting spots with one of these (with a ground in sharp tip)

http://www.diy.com/nav/decor/decorating-supplies/painting-decorating-tools/knives___scrapers/-specificproducttype-scrapers/Hamilton-Perfection-Chisel-Or-Lamp-Knife-37mm-9254674?skuId=9262373" onclick="window.open(this.href);return false;

Link - http://www.machinemart.co.uk/shop/product/details/clarke-cht685-spot-weld-cutter-set" onclick="window.open(this.href);return false;

I often wish for a smaller dia drill bit though - most seem to be around 8 mm which is good for quick unpicking but sometimes I want to go around 4 or 5 mm if I will be reusing the removed panel - I have to then use a standard 4 mm drill bit and hit the centre bang on with the centre punch first and then drill really carefully. It depends on how well looked after the tips of the spot welder were in the factory!!

Not that you asked but I am having a lot of success splitting spots with one of these (with a ground in sharp tip)

http://www.diy.com/nav/decor/decorating-supplies/painting-decorating-tools/knives___scrapers/-specificproducttype-scrapers/Hamilton-Perfection-Chisel-Or-Lamp-Knife-37mm-9254674?skuId=9262373" onclick="window.open(this.href);return false;

Fortunate Son

Well-known member

Most decorators knives won't cut it (pun intended!) but these ones are made of top quality spring steel and increase in thickness as they go towards the handle and, most importantly they are a single pice of steel from sharp end to the end of the handle, so they transfer the impact nicely. I would recommend wrapping the wooden handle many times in string tape though.

Happy despotting!

Andy

Happy despotting!

Andy

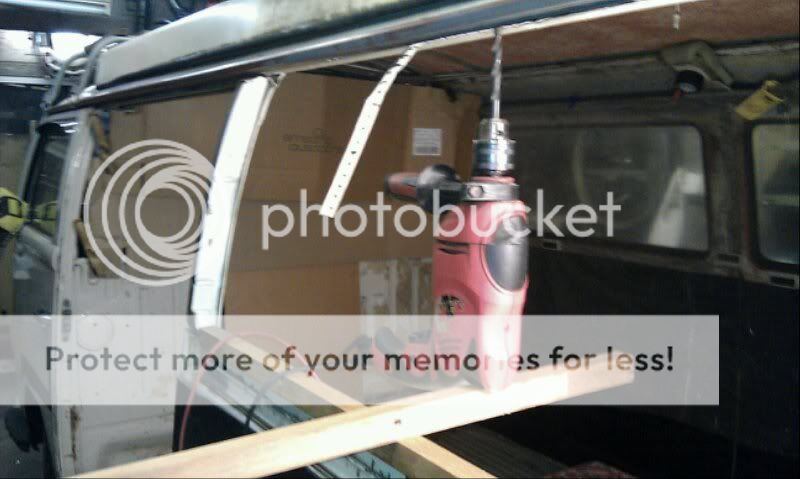

I did a fair old few spots not so long ago, parting a couple of roof panels amongst some of the stuff. I found the little hole cutter type from machine mart were ok but very very slow going. When down at B.O.C. for some gas I spotted these De Walt Extreme drill bits but thought I`m not paying that for a drill bit :shock: I was chatting to the blokey chap in there at the counter and he told me that when the bosses come in they won`t pay for them, but when the working dudes come in, they just grab one. I ended up buying three, a 6 a 7 and an eight. Let`s put it this way, I`d gone through four or five of the machine mart ones on both sides (double sided) and was about a quarter or a third of the way through the work,, well long story short :roll: I still got all three of the De Walt bits and they are still fresh. The only thing is ,,, they are a bit too good in that once the point is through they can drag the bit through in no time at all and you`ve drilled through both sections in a flash so you have to be really steady with the drill and not lean on it too much. But honestly they are so much quicker especially with a decent drill capable of slow slow speeds. AND if you can whizz something up to give you a bit of extra muscle and leverage then all the better

That bit of leverage made so much difference to taking out that window, spot by spot. I also used a variety of old scrapers but as above you really need good quality ones that have the metal all through but I just taped my handles up with insulation tape and beat seven bales out of them, drilled a load of spot welds first then used the scraper like a cold chisel but tapped in from either side and sometimes from three or four directions especially if the metal starts to tear. Good gloves, ear plugs and defenders and a hat etc etc etc, it all gets a bit sharp in places.

That is one of the scrapers :msn4:

And here is lots and lots of spotwelds X 2 as the old roof had to come off first :shock:

And look towards the rear of the roof and particularly at the rear gutters

Ozziedog,,,,,,,,,,,,,,,, Oh ,, do have fun :lol: :mrgreen: :lol:

That bit of leverage made so much difference to taking out that window, spot by spot. I also used a variety of old scrapers but as above you really need good quality ones that have the metal all through but I just taped my handles up with insulation tape and beat seven bales out of them, drilled a load of spot welds first then used the scraper like a cold chisel but tapped in from either side and sometimes from three or four directions especially if the metal starts to tear. Good gloves, ear plugs and defenders and a hat etc etc etc, it all gets a bit sharp in places.

That is one of the scrapers :msn4:

And here is lots and lots of spotwelds X 2 as the old roof had to come off first :shock:

And look towards the rear of the roof and particularly at the rear gutters

Ozziedog,,,,,,,,,,,,,,,, Oh ,, do have fun :lol: :mrgreen: :lol:

I din not like the one from machine mart. i used one from screwfix and re sharpened it on the grinder, but the new one they sell now has a different tip.

http://www.screwfix.com/p/exact-spot-weld-miller-8-x-80mm/84392?_requestid=560695" onclick="window.open(this.href);return false;

http://www.screwfix.com/p/exact-spot-weld-miller-8-x-80mm/84392?_requestid=560695" onclick="window.open(this.href);return false;

$125.45

Revell 07009 Volkswagen T1 Samba Bus Model Kit, 1:16 Scale 27.2 cm, Multi-Color, 223

Outstanding Outlet USA

$28.15

$32.44

Airfix Quickbuild Volkswagen Light Blue Camper Van Brick Building Model Kit, Multicolor

Amazon Global Store UK

$27.95 ($13.98 / Count)

Marketplace Auto Parts Window Crank Handle Set of 2 - Chrome with Black Knob - Compatible with 1968-1978 Volkswagen Beetle

Parts Geek LLC

Fortunate Son

Well-known member

Just to clear up what I meant about machine mart spot weld drills-

The ones sold individually like this are *****, agreed, the teeth come off really quick if you drift off centre and they blunt quickly too.

The set I was referring to is this one and the barrel type drill has more teeth and does not blunt so quickly.

Having said all of that, I have only ever unpicked front arches, rear corners, sills and front panels, I've never done a roof, that's just sadistic spot weld drilling!!

The ones sold individually like this are *****, agreed, the teeth come off really quick if you drift off centre and they blunt quickly too.

The set I was referring to is this one and the barrel type drill has more teeth and does not blunt so quickly.

Having said all of that, I have only ever unpicked front arches, rear corners, sills and front panels, I've never done a roof, that's just sadistic spot weld drilling!!

Hi Fortunate ,, ^^^ I have not seen those other ones in there and I had the crappy ones like you said. The other ones look a bit more like it, how does the outer bit fit to the bit then or is it just a little grubby screw ?? The main drill bit looks almost the same as the De Walt extreme ones I was rattling on about. If you ever see one try it I think you`ll be just a bit impressed, they`re almost like the one you`ve pictured but a bit goldy or bronzish to look at. As for the sadistic bit with unpicking a couple of roofs, it was needs must and all that stuff, took bloody ages too :shock: Now I look back on it i think it was just the first part :mrgreen:

Ozziedog,,,,,,,,,,,,,,Just Sad,,,,,,, :lol: :roll: :lol:

Ozziedog,,,,,,,,,,,,,,Just Sad,,,,,,, :lol: :roll: :lol:

Similar threads

- Replies

- 12

- Views

- 766

- Replies

- 1

- Views

- 318