another half arsed update i'm afraid. i will get around to taking some up to date pictures but for no...... here are some i found on an old memory card (4 years ago! :msn4: )

in no particular order;

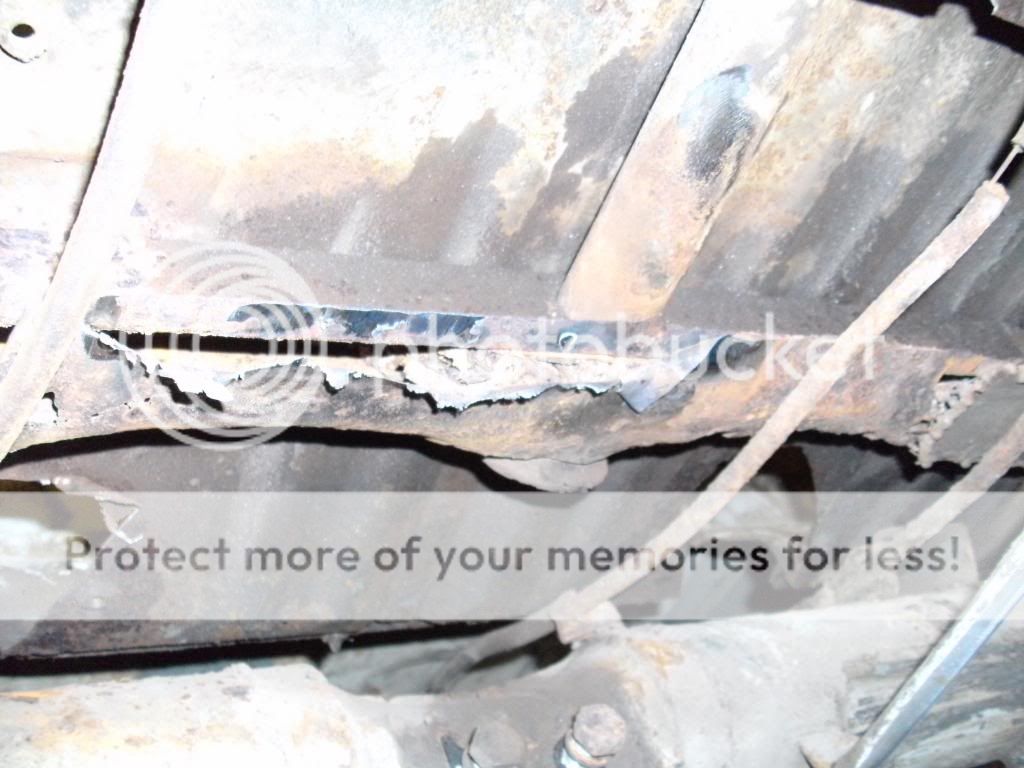

^ those are 'restoration repairs' by the previous owner

the entire van (and about £500 worth of schofield panels had been welded in in a similar fashion!!!) in quite a few places (inner sills particularly) there was still loads of remnants of the original panels that the new ones had just been squashed over and welded on top of! it left a lump in my throat as i was doing it but i painstakingly removed EVERY single previous repair panel that had been welded into it. this included;

both full front arches

all out riggers

all jacking points

lower front panel

inner and outer sills both sides

lower front and rear/ rear arch repair sections

both rear corners

both battery trays

aswell as contending with that lot the van was still riddled with rot too, both cab floor sections had plat plate badly welded over them. the 3 belly pans were rotten and badly plated so i removed them to find most of the chassis missing at the passenger side (!) and a fair amount of rot on the drivers side just behind the beam too. i was in disbelief that sills and outriggers etc had been birdshitted back on but the lack of chassis rails had just been ignored :shock: the van was in a terrible state structurally when i got it, because of the shonky repairs and lack of chassis the only door that shut properly was the tailgate! not good when your van has 4 other doors!!! clearly none of it had been braced or measured gap wise before the cutting and welding started :roll:

...........anyway, cut a long story short unfortunately i had to mangle/ hack virtually all the replacement panels that had been fitted to remove them. managed to save a couple of jacking points but that was it. bought the same lot from schofields and started again. (with the exception of the front arches, they were original cuts from a cali van).

^ that picture is the start of my repairs. i didn't use rusty plate to weld it up, it was actually brand new clean metal when i started.... just took me so damn long between completing the repair and taking a picture that the clean shiny metal turned to surface rust!!! nothing that won't rub off when i'm prepping it for paint later on though.