Right - now I have got myself a slightly more modern welder than my 1992 SIP Handymate, I have discovered the joys of (relatively) decent welding, so I am going to start tackling some of the bits on my van.

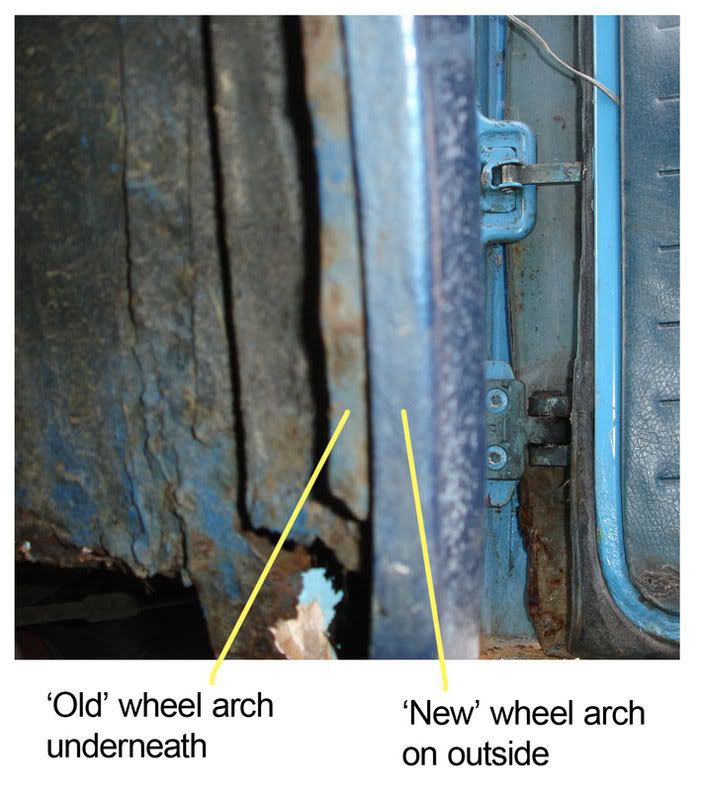

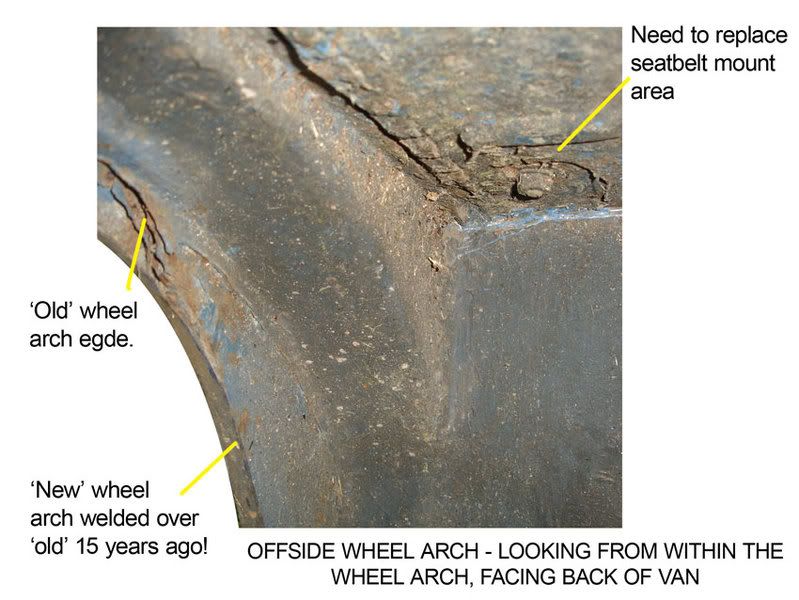

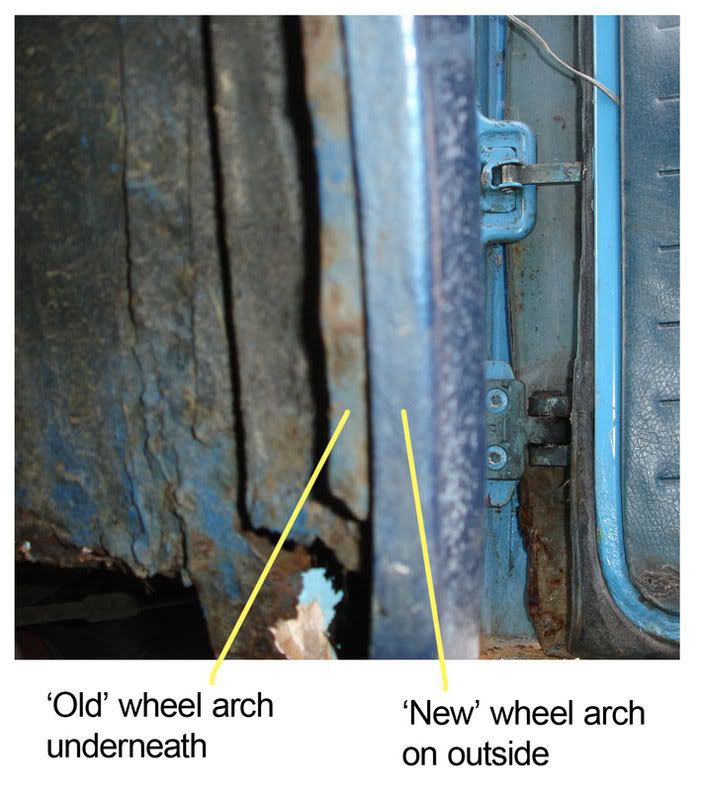

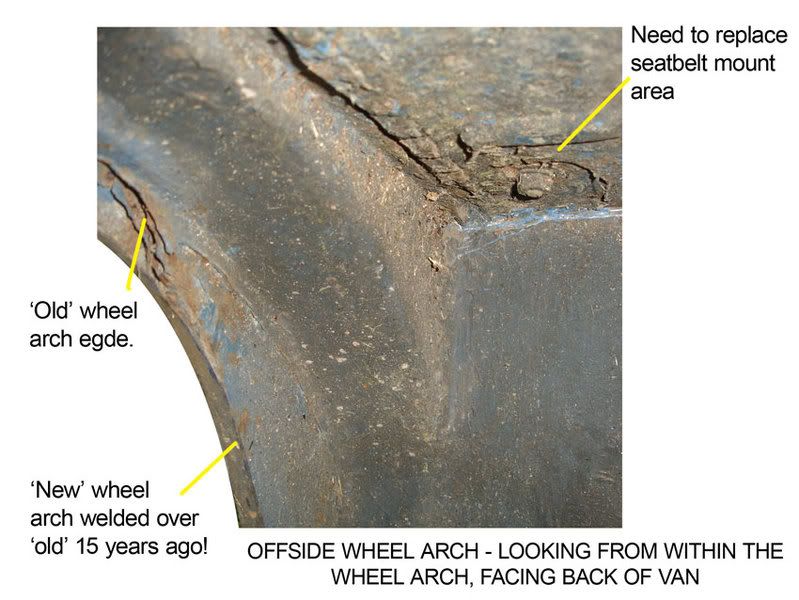

I'm lucky in that there isn't a huge amount, but one area that does need attention is the front wheel arches. Years ago, we repaired these by welding some new panels over the old ones that were 80% still ok - just the edges gone. But that has left a nasty under-view of rough edges and dirt traps, so I may cut out all the layers and start again.

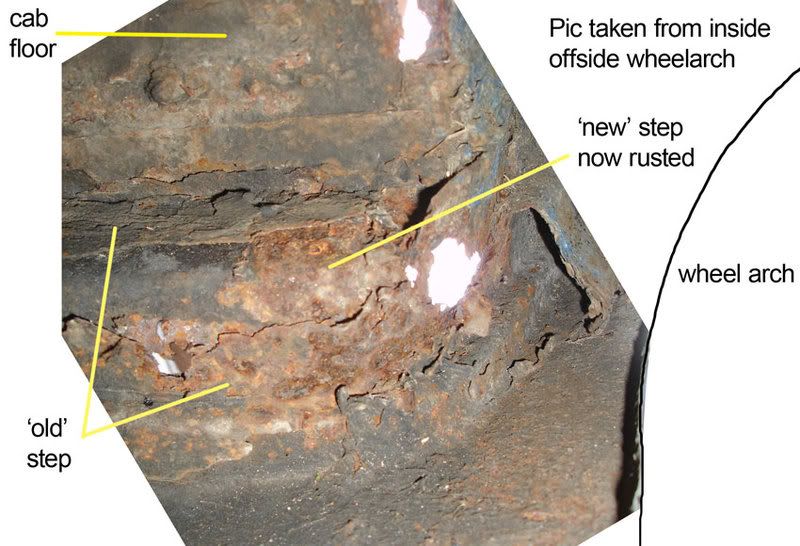

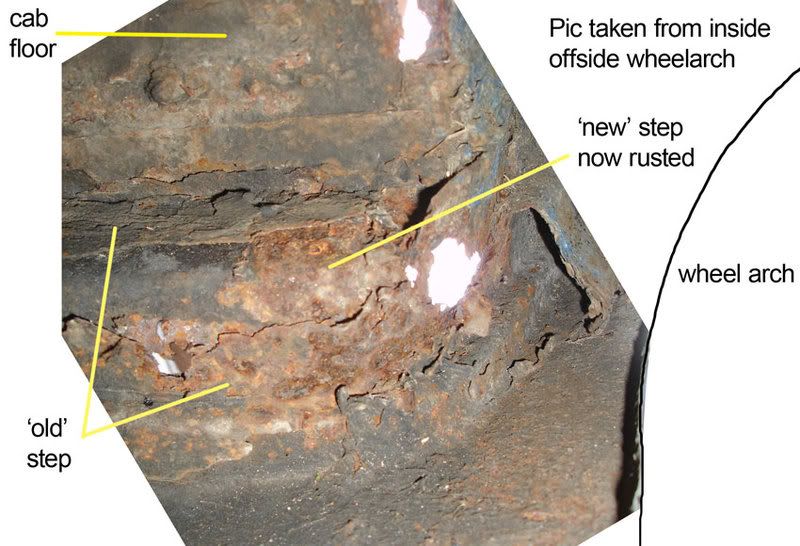

Quite hard to see what is going on in those pics, but basicaly I am sure I am missing an 'inner' step? Should there be a box section here?!

So - 2 questions. Does anyone know of a diagram that shows up the exact construction of various inner/outer layers around this area - all I have are the generally small illustrations used by the retailers to identify parts - I want a better look at things to see if I want to get a whole wheel arch, or just some of the smaller step inner/outer parts.

2nd question - I know a lot of the repair panel quality is pretty poor - but where would you shop for decent front wheel arches ad a few other bits and pieces. Don't need big panels like front skins, side skins etc - just a few 'detail' parts....

I'm lucky in that there isn't a huge amount, but one area that does need attention is the front wheel arches. Years ago, we repaired these by welding some new panels over the old ones that were 80% still ok - just the edges gone. But that has left a nasty under-view of rough edges and dirt traps, so I may cut out all the layers and start again.

Quite hard to see what is going on in those pics, but basicaly I am sure I am missing an 'inner' step? Should there be a box section here?!

So - 2 questions. Does anyone know of a diagram that shows up the exact construction of various inner/outer layers around this area - all I have are the generally small illustrations used by the retailers to identify parts - I want a better look at things to see if I want to get a whole wheel arch, or just some of the smaller step inner/outer parts.

2nd question - I know a lot of the repair panel quality is pretty poor - but where would you shop for decent front wheel arches ad a few other bits and pieces. Don't need big panels like front skins, side skins etc - just a few 'detail' parts....