I noticed one of the CV boots had split on the left side, wheel end of the drive shaft. Bought a kit for both boots as I thought that it would be best to renew both.

Looked at a lot of guides before doing the job from Ratwell's site and on the samba

http://www.thesamba.com/vw/forum/viewtopic.php?t=570473&highlight=constant+velocity" onclick="window.open(this.href);return false;

Also KYBA 5 (keeping your bus alive magazine) as well as on this forum.

Wasn't too bad a job just a bit mucky with all the grease, and the drive shaft is heavier than you think when you're on you your back trying to hold it up to re-fit it :lol:

Considering all the problems I could have had it went really easy; the CV joints came away from the shaft and back on without any problems, and the circlips both went back on by hand, I didn't need to use the 36mm socket to persuade them.

The main problem was trying to re-locate the joints back in position and getting the bolt-holes to match up with those on the wheel end and transmission end. I ended up using a screwdriver to just hold up the drive shaft whilst I grabbed the bolts to thread in.

Hope you like lots of pics. :lol:

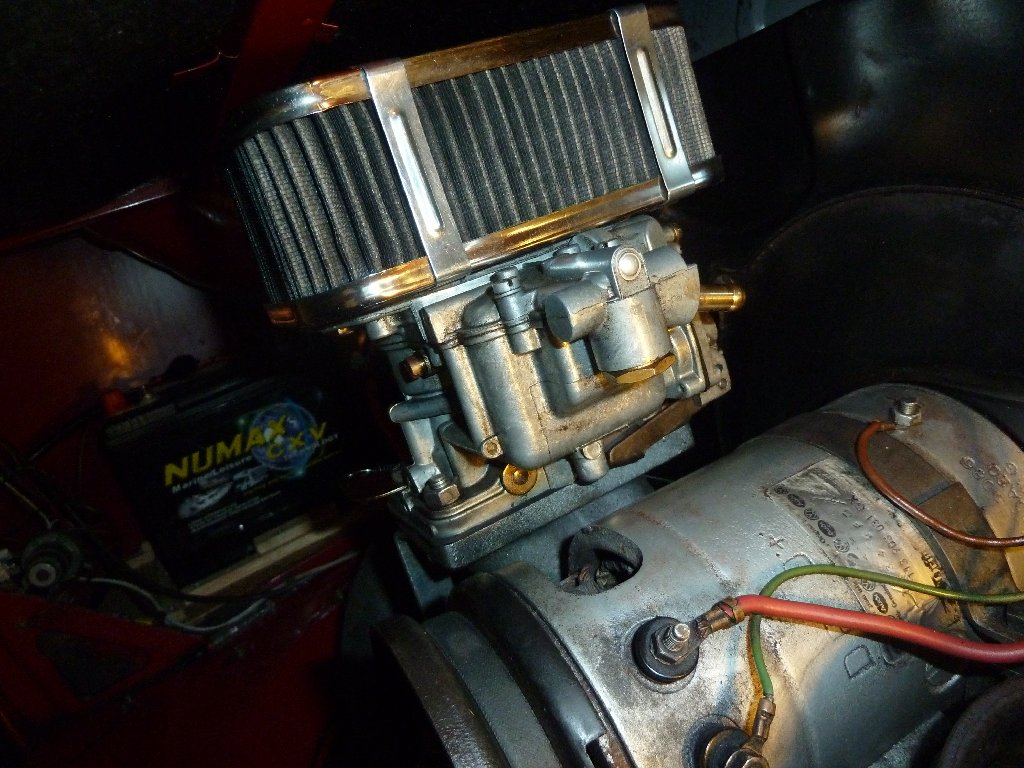

This drive shaft is a replacement and still has the part sticker on it. There are no clamps on the narrow end of either boot. Split boot, with the allen bolts cleaned up.

On the right side of the van this drive shaft is original I think, the boots look fine.

date stamp on the CV joint is 8/69

LHS shaft cleaned up in the vice

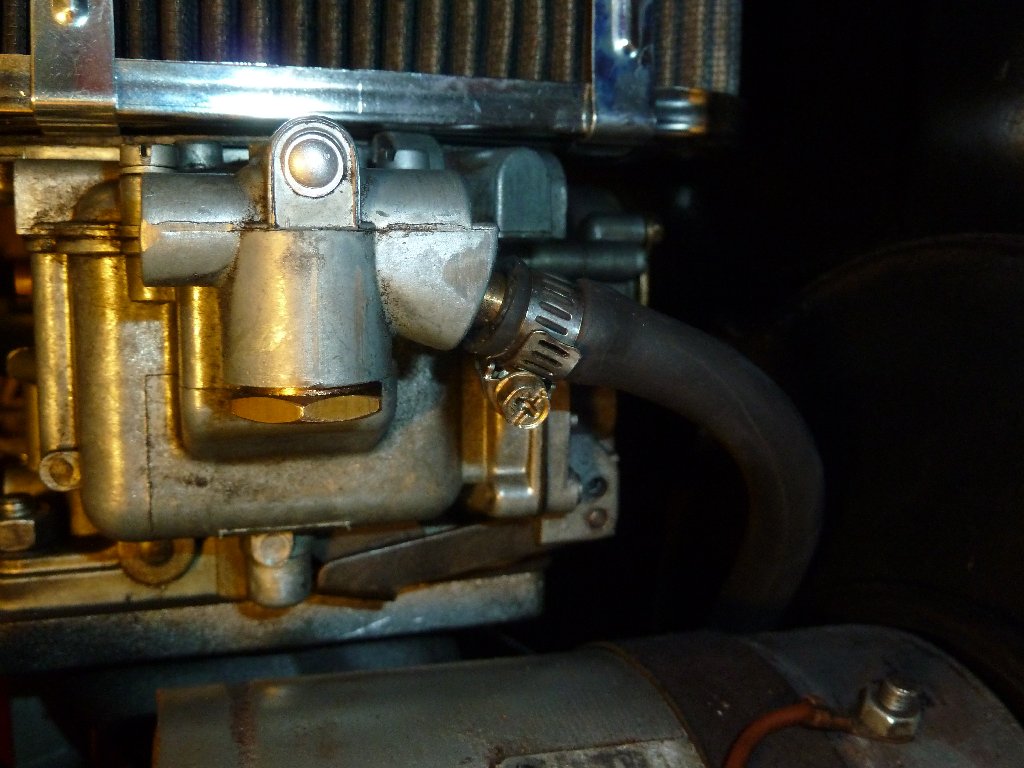

the CV joint with the split boot. The grease just looked a little darker green than the other side so I reckon I spotted it early and not too much rain/ dirt has got in there.

CV joint cleaned up - looks ok to me no scoring or burn marks

re-greased

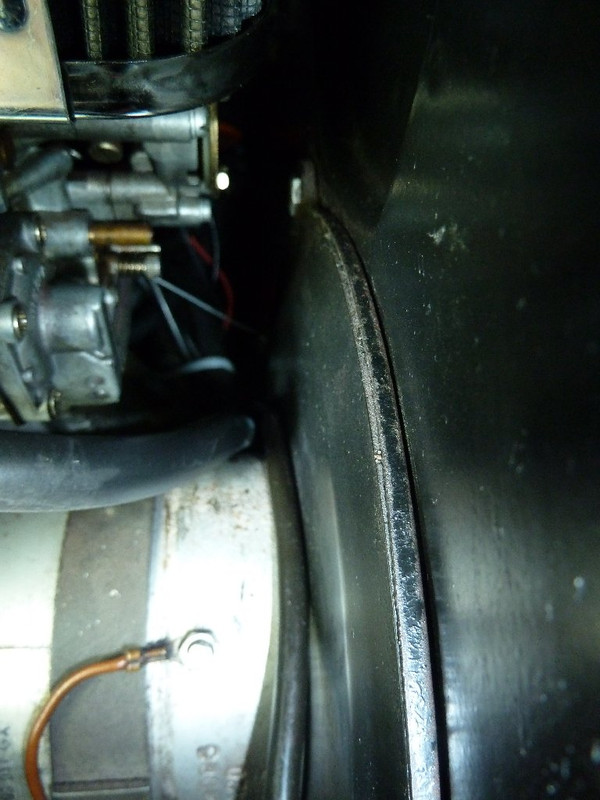

the new boot kit. I decided to re-use the dished washer rather than put the new one in. It seems to be quite a contentious issue, as Bentley says to discard these but as I said above the CV joint went on ok and the old circlips went on without trouble. I preferred to re-use the 'old' circlips as they looked in good condition.

re-fitting the drive shaft

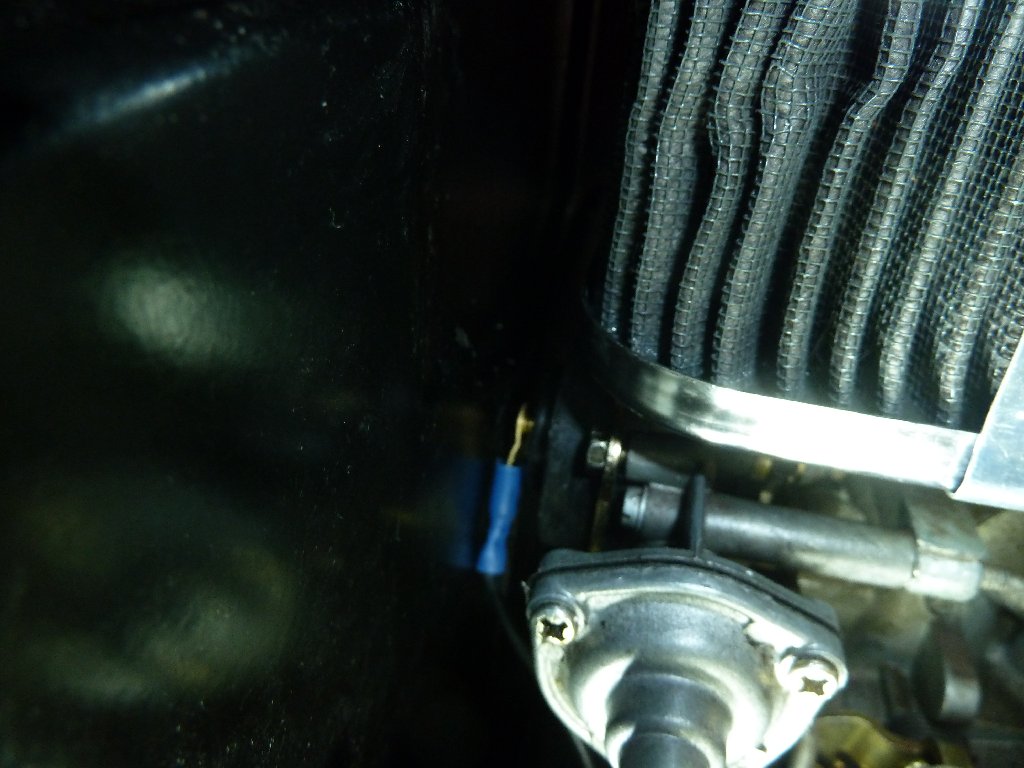

wheel side shot all fitted up, and with cable-tie as I couldn't fit the metal clip.

transmission end

Fingers crossed that it will last for a while! :roll: