Birthday boy at the end of next month and the wavey led headlight is on my wish list. Then I’ll be able to leave this other one velcroed on my welding helmet where it’s done some sterling work lately as it’s really helped me getting into the nooks and crannies and still being able to see. I still can’t see the weld pool but I can remember how it’s supposed to go with that wriggly wrist action (Ooooerrr) and so long as I can see to start off or somewhere near like in the same post code then I’m still good to go.

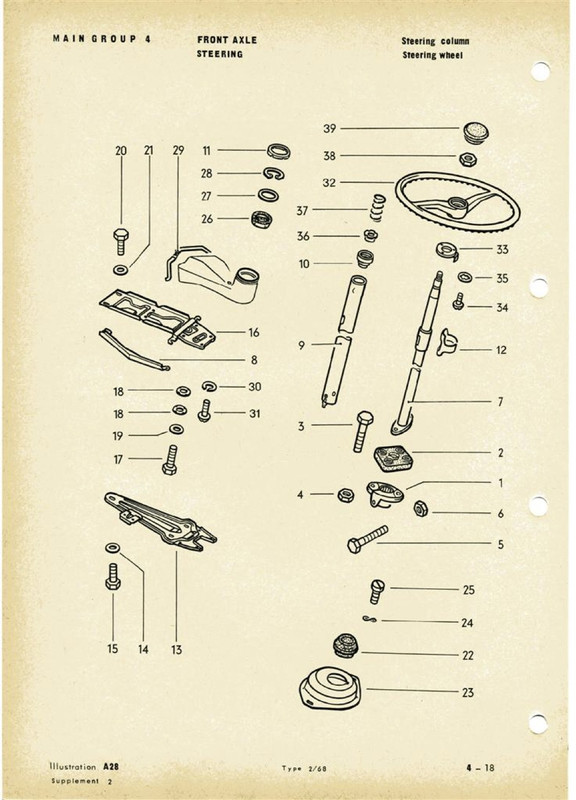

I’ve been trying to sort out putting this pedal pan on for a while now and it’s got pushed back and back because of lack of brakes etc etc etc then I noticed my flexi joiner thingy on the end of my steering column was indicating a few stress marks and I had one to change over from another van so that’s on my to do list that I’m doing today. So far it’s been a proper battle of wills. Started last night and thought to clean everything up and spray all nuts and bolts etc before going out for some food with the lovely Mrs Ozziedog. So got started today and an hour or so in and I’m getting nowhere then realised all the nuts had a split pin through that had done a mind meld with the nuts and the bolts so after an hour or so of trying, I then relinquished and got serious with the grinder and cut half the nut off each one. Next battle of wills is how to get the top two bolts out ? Luckily I’ve got some bits here that I could look at to try and see what I was up against, no luck, I’m thinking if I’d left the hold down plate bolted on then I may have been in with a chance. So now I’ve dropped the steering column from the dash and put the steering wheel by the ash tray and got the other end on a beer crate to see where I was going wrong. In this position it was almost easy, top tip was to use some mini mole grips to take the bolt out while leavering the column end down for clearance and and as the book says, installation is the reverse procedure. Once I got it out, I could see the male spade connected to the outer column but I was still totally at sea with how the damned thing worked. I knew the horn was ignition fed permanently live but I could not for the life of me work out what was going on after that, until I saw the spade connector. Part of the issue is that my brain fogs up a bit as soon as that word is used,,, electrics

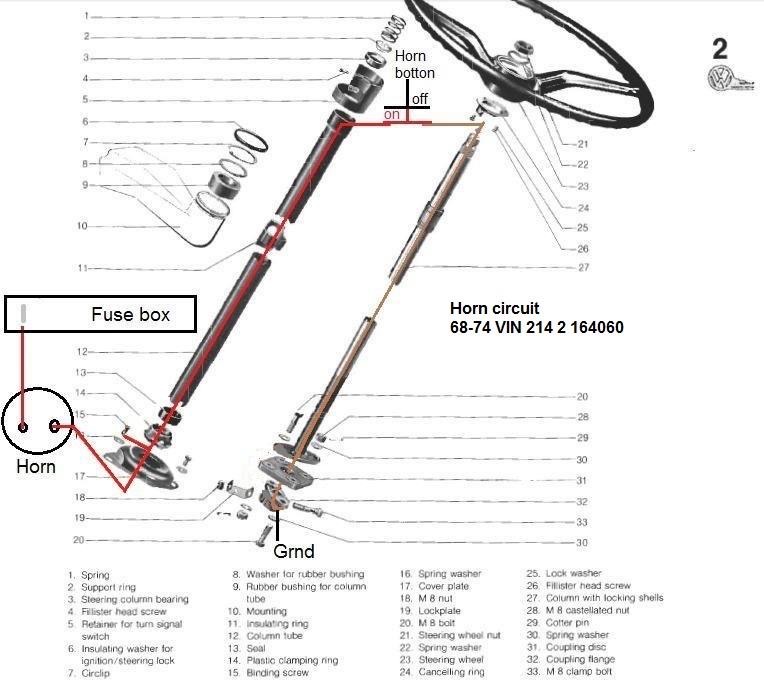

Another part of the issue is I’ve been reading up on it and it would appear there are two different systems, one for the Earlies and one for the Lates. I just couldn’t work out why the horn wasn’t going off all the time and how the earth switch worked. So if I’ve got this right, it’s permanent live when the ignition is on to the horn. The earth then comes from the horn and connects to the fixed spade terminal on the steering column via a little clip in the column holder down plate this is then connected via the column outer to the horn push which is then part of the circuit through the wire going down the column and bridged across the flexi coupler to earth out through the steering box.

Or so I think. So I’ve got the top two old bolts out and the new bolts in. Let’s put it back together and see where we are. Could it be any more complicated guys ???

Ozziedog,,,,,,,,finished lunch so back on it.