I have just finished installing a pair of Weber 34 ICT carbs to my 1600cc aircooled engine running electronic ignition from a vac advance dizzy which has had the timing checked and is less than 2 months old.

I re-jetted the carbs using parts from Eurocarb

Now have F6 Emulsion tubes to replace the oversized F78's

2 x 150 Main Jets to replace the 140's fitted

Idle jets 55's

Have balanced both of the carbs with assistance of a airflow meter and also have the manifolds tapped and balance pipe fitted behind the fan shroud.

CSP bellcrank linkage is installed and correctly adjusted to give full opening of the throttle.

I am running an Antipulse valve (arrow towards carbs) from the dizzy to a t-piece and off to both carbs - have checked the vac advance and it is all working correctly.

The engine starts easily when cold or hot, idles correctly and revs cleanly when not under load however when on the road out of first gear it splutters, coughs, misses and eventually dies. Has no power and wont rev.

Once I have come to a stop the bus starts again and revs cleanly until you get going again where it repeats.

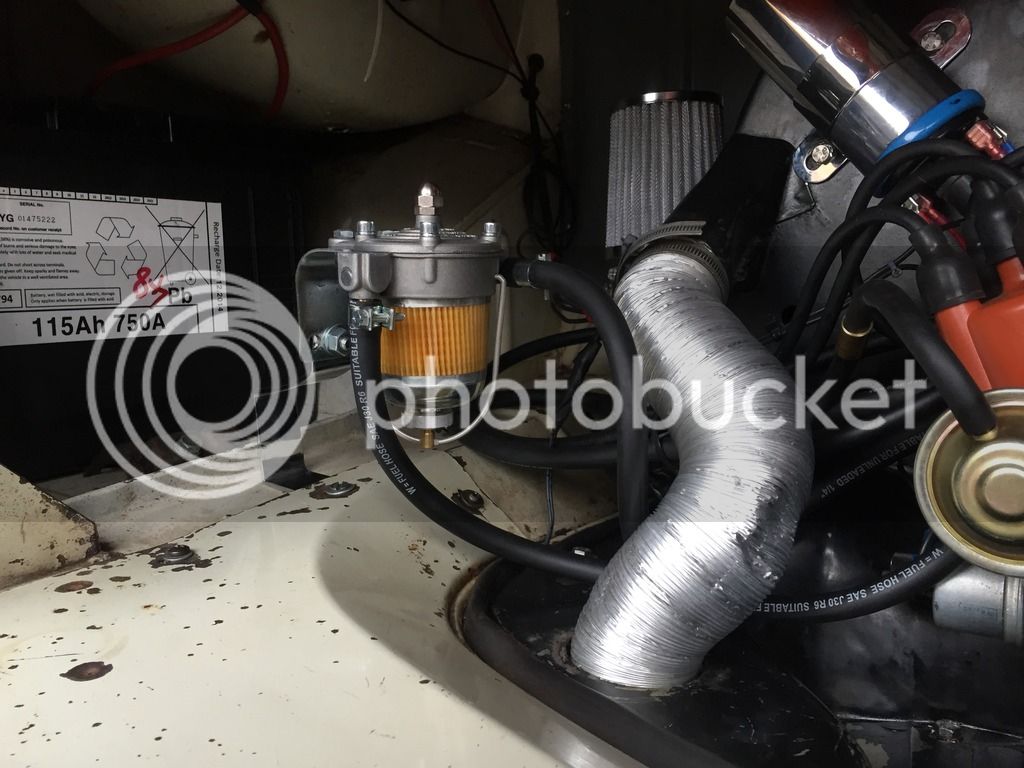

We have checked the fuel pressure and adjusted it to 3psi through my Malpassi fuel pressure regulator.

All the ht leads appear to be tight and the coils resistance checks out within spec.

The carbs have been checked for air-leaks and new gaskets and seals have been used in the install.

Anyone have an idea why it would keep bogging down and running poorly when under load? Cant really think of anything else?

Adam and I spent a couple of hours this eve setting up the carb linkage, mixture and idle but out on the road you cant go more than 100meters without it spluttering to a stop

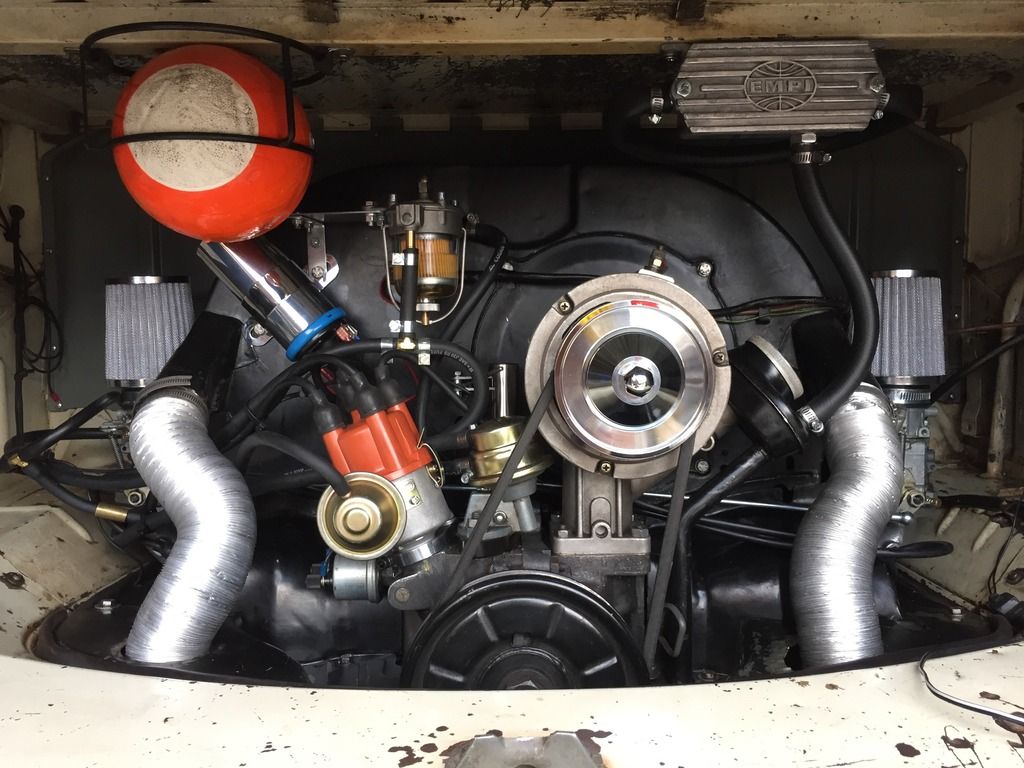

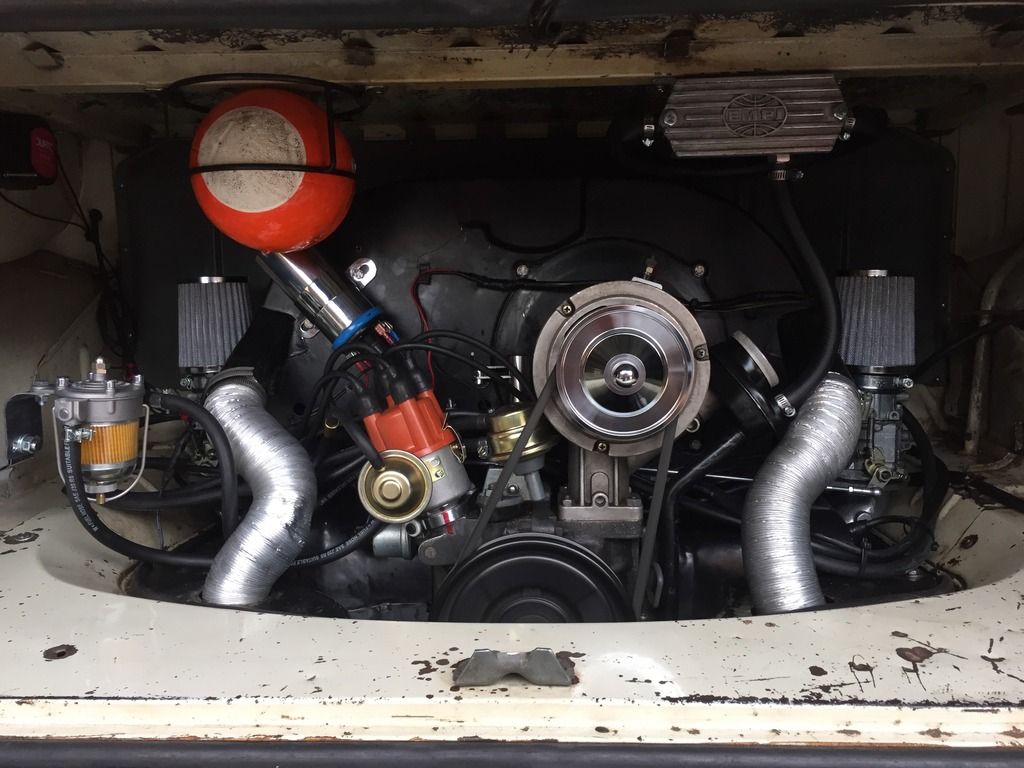

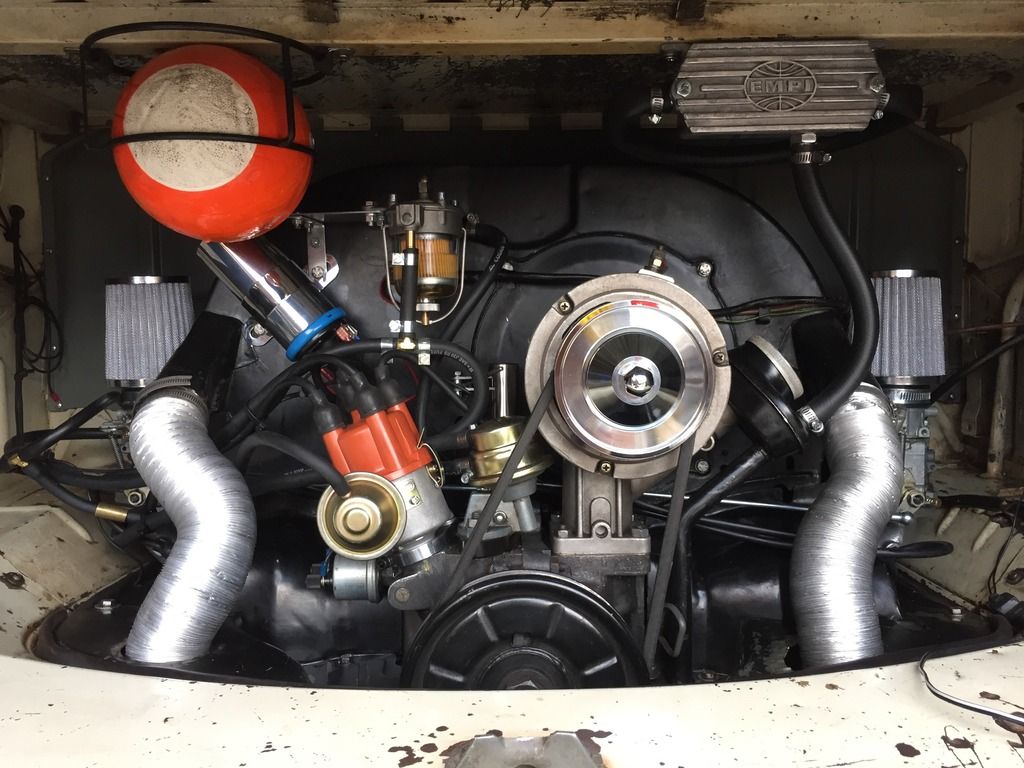

Pic of the engine

I re-jetted the carbs using parts from Eurocarb

Now have F6 Emulsion tubes to replace the oversized F78's

2 x 150 Main Jets to replace the 140's fitted

Idle jets 55's

Have balanced both of the carbs with assistance of a airflow meter and also have the manifolds tapped and balance pipe fitted behind the fan shroud.

CSP bellcrank linkage is installed and correctly adjusted to give full opening of the throttle.

I am running an Antipulse valve (arrow towards carbs) from the dizzy to a t-piece and off to both carbs - have checked the vac advance and it is all working correctly.

The engine starts easily when cold or hot, idles correctly and revs cleanly when not under load however when on the road out of first gear it splutters, coughs, misses and eventually dies. Has no power and wont rev.

Once I have come to a stop the bus starts again and revs cleanly until you get going again where it repeats.

We have checked the fuel pressure and adjusted it to 3psi through my Malpassi fuel pressure regulator.

All the ht leads appear to be tight and the coils resistance checks out within spec.

The carbs have been checked for air-leaks and new gaskets and seals have been used in the install.

Anyone have an idea why it would keep bogging down and running poorly when under load? Cant really think of anything else?

Adam and I spent a couple of hours this eve setting up the carb linkage, mixture and idle but out on the road you cant go more than 100meters without it spluttering to a stop

Pic of the engine