Thanks everybody for the kind comments. Sorry its been such a long time since the last update.

My project stalled for three weeks because i could not get any endfloat shims size 36 - I needed 3 of them. In the end I gave up trying and got the clearance by using four shims (3x24 and 1x 34). Although the book sais use three i could not see any technical reason why i could not use four.

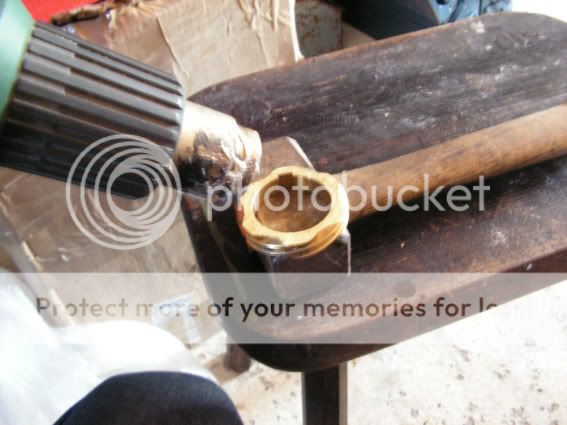

This pic shows the new engine and the full flow system. The tin behind the pully needs to be hammered to clear the brass fitting in the block. The connection on the oil pump exactly clears the engine mouting bar so no mods necessary here.

The tinware all went on quite easily requiring only the usual amount of fiddling to get it all sitting right. The gearbox has been changed with a recon one from a 2 litre with a 4.57 diff.

The clutch is a keneddy stage 1 since the standard clutch starts to slip at above 100bhp apparently. Kennedy reccomend you tighten the bolts to 30 instead of 23 ftlb. I had to go and get some high tensile bolts because when i tried to take the standard bolts up to 30 they snapped.

To my amazement the manifolds supplied with the weber carbs did not have any provision for a brake servo take-off. I used my little mig welder and with argon gas and welded a big blob of alloy onto the manifold a little below the carb mounting flange. Once machined down it gave me enought meat to drill and tap to screw in a gas fitting.

The engine was a lot more fiddly to fit back in the van since it now has to go in at an angle since the carbs wont clear the chassis/body so where it used to take me about 40 mins before, it now took me a couple of hours.

The remote filter tucks up nicely out of the way whist still being very easy to access. The brass unions supplied to fit into the oil filter top leaked like a sive however tight you screwed them in. I had to remove them and seal them with hylomar and plumbers hemp.

Before fitting the exhaust i looked at the heat exchangers and noticed the weld in the flange end was very thick - more so on one side than the other, so i ground these down and gained (on the bad side) 2 mm of port diameter.

The four into one stainless header is a tight fit and only just clears allowing you to keep the rear panel and engine bar un-modified. Very precisely made - though, to my surprise, the support bracket for the silencer dit not meet the supplied mounting clip and I had to make a small extension to fit between the two. Its only a steady to prevent excessive vibration so its not a major problem - just a bit odd that with all this precision in the manufacture they made such a silly error.

As you can see in the picture, the exhaust sits about 4 cm lower than the original and I shall have to be a little more careful in future when going "off road". If this is the "quiet pack" I dread to think what the noisy one is like. I have to be careful not to accelerate too much in town since its quite noisy.

Heres what the engine looks like installed.

It was quite fiddely making the tubes from the heat exchangers come up through the tinware (because the 4 into1 does not have the little intermediate boxes).

The Idf 40's are lovely carbs and really easy to set up. They also have a vacuum take-off for the distributor which is ideal since i dont like 009's because they tend to give flat spots when pulling away and also dont give the extra advance on light throttle that improves fuel consumption.

I had to drill and tap the top of the aircleaner since there is no provision to attatch the engine breather tube.

As you can see I am testing a helper spring on the throttle lever. The linkage is well made and works well but is stiffer than the original so i have fitted a spring to help close the throttle. Once tested I shall make something a little more tidy. I also had to make the throttle cable tube a tighter fit in the fan housing since it tended to push through and leave me with only quarter throttle.

I have started running in the engine and the difference is unbelievable. The power and torque make it a pleasure to drive. At 80 kph its doing 2100 rpm. It barely notices inclines that used to be a struggle in top or required revving in third. Oil temp is between 90 and 100. Pressure max 5 bar cold, 3bar hot at 2500 rpm and 1.5 bar at tickover hot.

In conclusion:-

Although I have worked on VW aircooled engines for some years I had never before built one up "blueprinted" from all new and non standard parts so I was a beginner. If you are thinking about doing something like this then as long as you can cope with a standard engine build you will be able to do this. It just takes more time and care and you have to read up a lot to get all the info you need.

I listened to the professionals and took their advice as to the combination of modded parts that should go to make up the engine I wanted. I also read a lot on the web and bought the "interchange manual" and read it cover to cover.

My thanks to Paul at speedshop for his advice. I ended up buying nearly everything from Speedshop and all the parts fitted perfectly and were of good quality. (please note I have no connection with them and only got to know of them through their advert on the vzi forum)

Time - you need plenty of it. From my start in december it has taken seven months to finish. There is a lot of demand for performance stuff and limited suppliers, so you have to be patient and wait to get all the right parts and get the machine work done.

Specs - go for the best quality you wont regret it. Keep in mind the driveability of your road vehicle - keep it reliable and keep it driveable - nothing more tiresome on a long run in traffic filled roads than an over cammed engine. For normal driving torque is more important than bhp in my opinion.

Costs.

Well the basic engine was over £2000 and once you add in all the extras like stainless 4 into 1 header and exhaust, competition clutch, twin weber idf's its well over 3000.

Plus of course the 1000 for a rebuilt gearbox (mine was/is in perfect working order but at 70,000 miles it seemed a little foolish to put a 4.57 diff in it so i went for a complete recon unit instead.

So was it worth it?

Well I always wanted to build a blueprinted engine and I thought if I dont do it soon I probably never will.

If I wanted to go faster I could have taken the van back to England, sold it and bought a later square watercooled injection camper for less money than i sold mine for.

If I were to sell my van now its value has not risen anything like as much as I have spent on it.

So am I an idiot? - probably yes. But I am having fun