Question to you folks running ICT carbs (and maybe others depending on the fuel pipe position).

Whilst I was poking around my engine bay this weekend, I noticed that some of my fuel lines were perishing on the outside - a common problem it seems if the bends have been made too tight. I won’t mention that I also managed to dislodge one of the lines and drained most of my fuel tank onto the garage floor before I could get a jack underneath it to stem the flow [emoji23]. Certainly I’m now looking at changing around a few lines to make the runs straighter, but the one that I don’t know what to do with is the inlet to the left hand carb. Worst case, I’ll pop a couple of 90 degree elbows in there, but ideally I want a sweeping bend to minimise joints. I can’t seem to find anything that exists with some barbs to help grip the fuel line. What have others done?

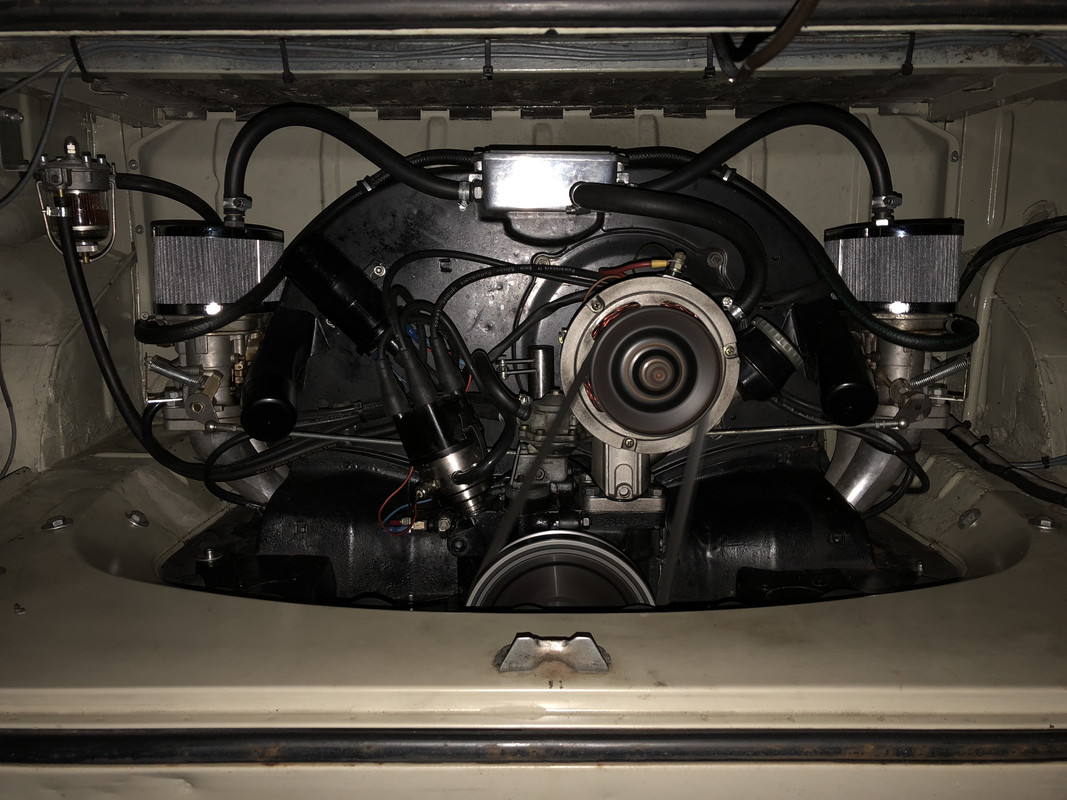

And a photo of one of the perished lines (which is going to be replaced with a proper 90 degree outlet), but I was surprised at how this had started to fail given it is less than a year old and not at a particularly tight angle:

Sent from my iPhone using Tapatalk

Whilst I was poking around my engine bay this weekend, I noticed that some of my fuel lines were perishing on the outside - a common problem it seems if the bends have been made too tight. I won’t mention that I also managed to dislodge one of the lines and drained most of my fuel tank onto the garage floor before I could get a jack underneath it to stem the flow [emoji23]. Certainly I’m now looking at changing around a few lines to make the runs straighter, but the one that I don’t know what to do with is the inlet to the left hand carb. Worst case, I’ll pop a couple of 90 degree elbows in there, but ideally I want a sweeping bend to minimise joints. I can’t seem to find anything that exists with some barbs to help grip the fuel line. What have others done?

And a photo of one of the perished lines (which is going to be replaced with a proper 90 degree outlet), but I was surprised at how this had started to fail given it is less than a year old and not at a particularly tight angle:

Sent from my iPhone using Tapatalk