andewilson

Well-known member

my lovely wife and kids have gone to cleethorpes for a few days as of yesterday arvo  . this will be there longest time i have been apart from her in 8 years. one plus point though is i went round last night night and recruted a few boys to get it flipped again.

. this will be there longest time i have been apart from her in 8 years. one plus point though is i went round last night night and recruted a few boys to get it flipped again.

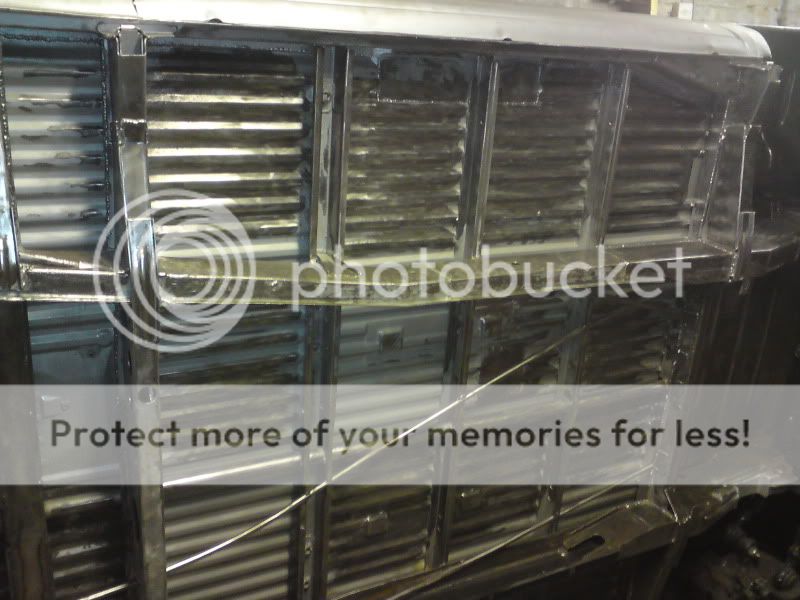

probably dont need to notch my van but all you guys are doing it and i felt a little left out so here goes

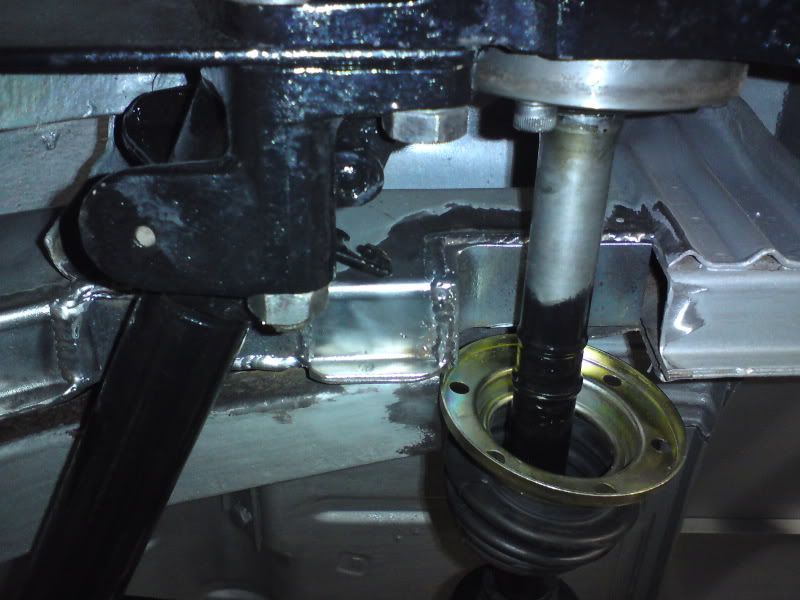

a little clearance for the trailing arm which a lot of folks seem to forget about. only around 15 mm of clearance but it all counts

then to the drive shaft

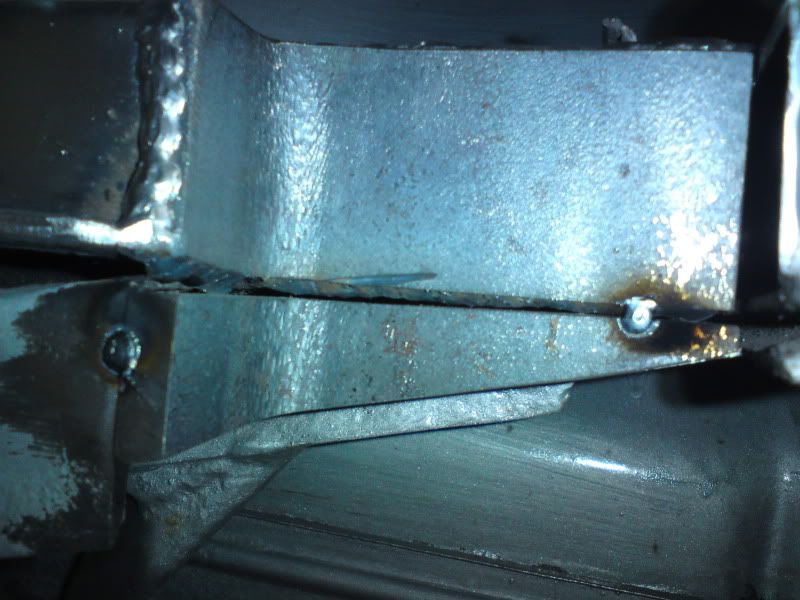

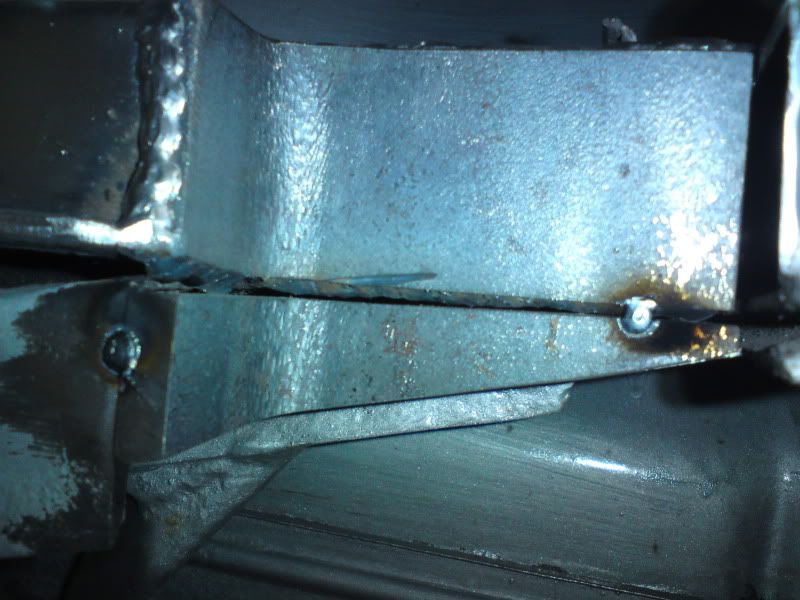

i did the notch in two sections to make sure the chassis was fully welded all round then the diagonal section welds to it

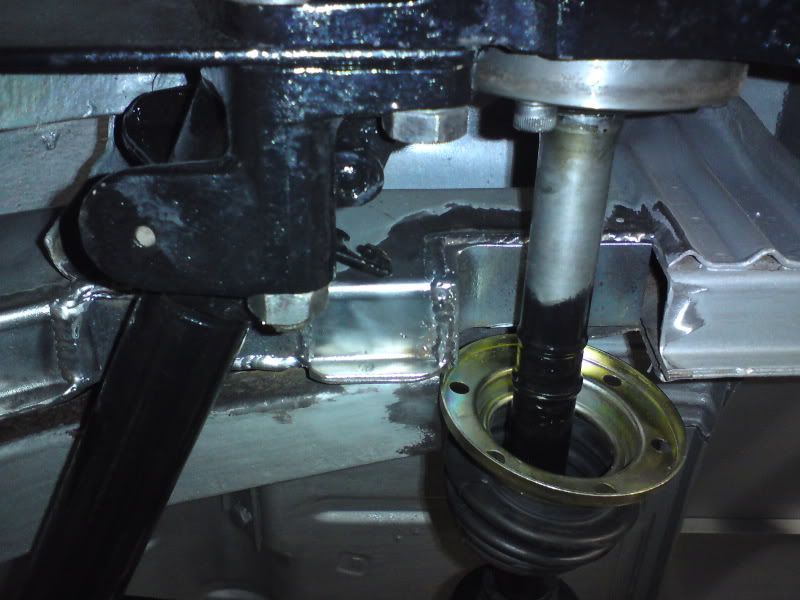

little bit of clearance on the arm pivot

bit of camber

probably dont need to notch my van but all you guys are doing it and i felt a little left out so here goes

a little clearance for the trailing arm which a lot of folks seem to forget about. only around 15 mm of clearance but it all counts

then to the drive shaft

i did the notch in two sections to make sure the chassis was fully welded all round then the diagonal section welds to it

little bit of clearance on the arm pivot

bit of camber