G

Guest

Guest

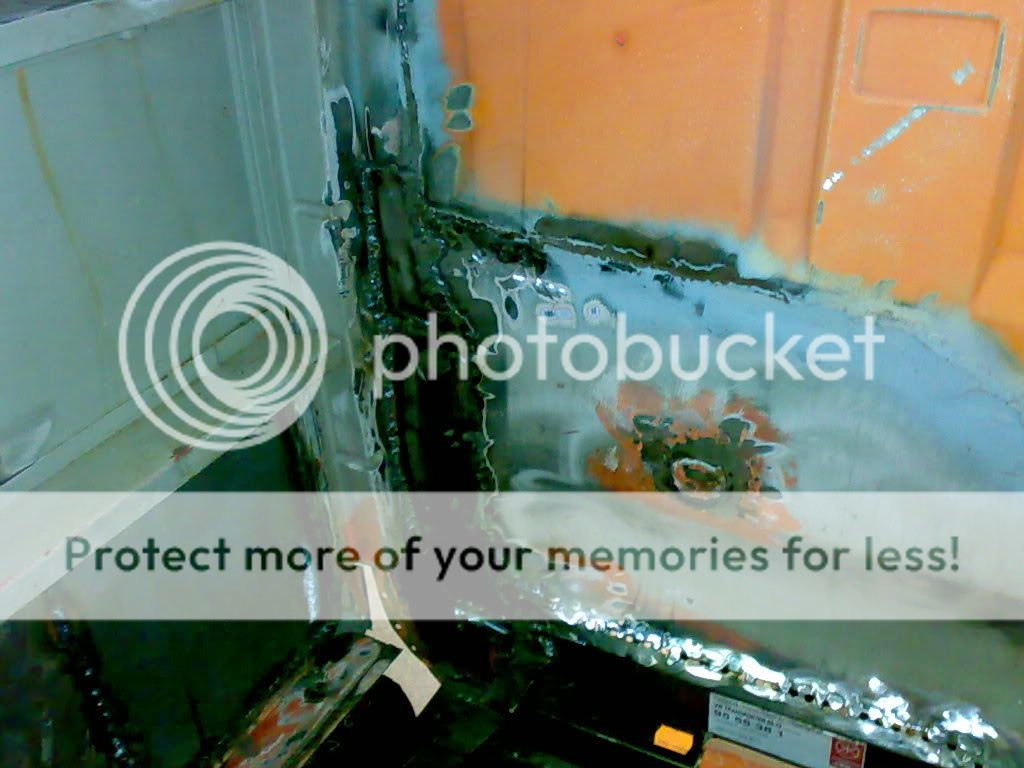

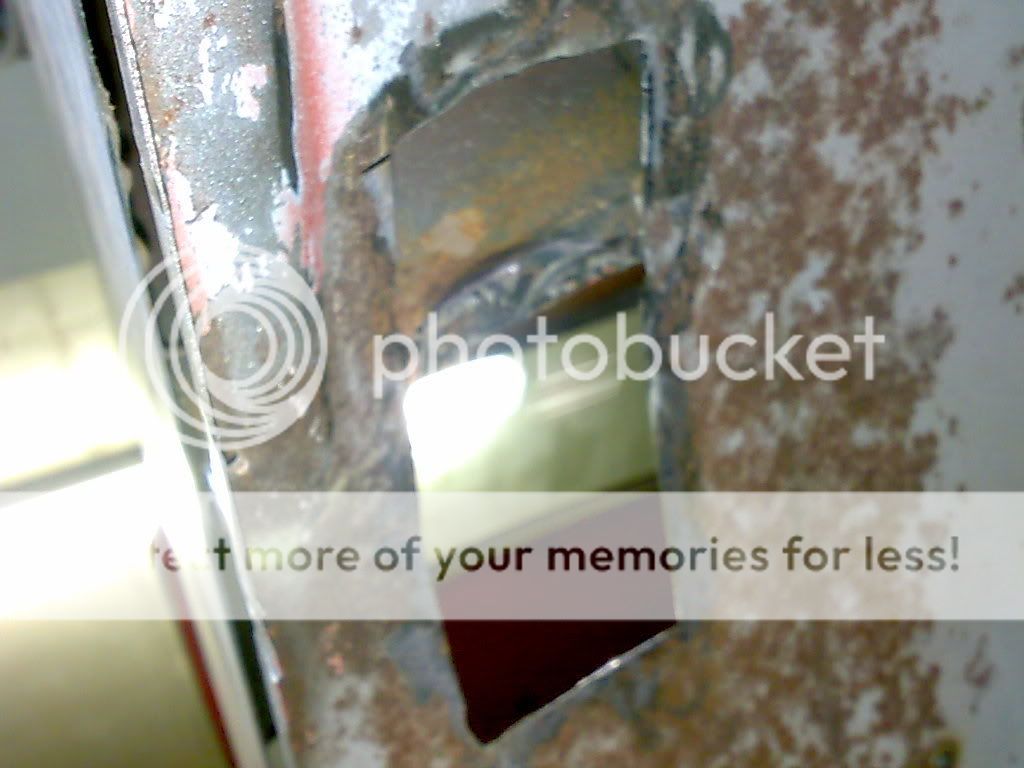

did you use nitromorse? and did you rinse with water?

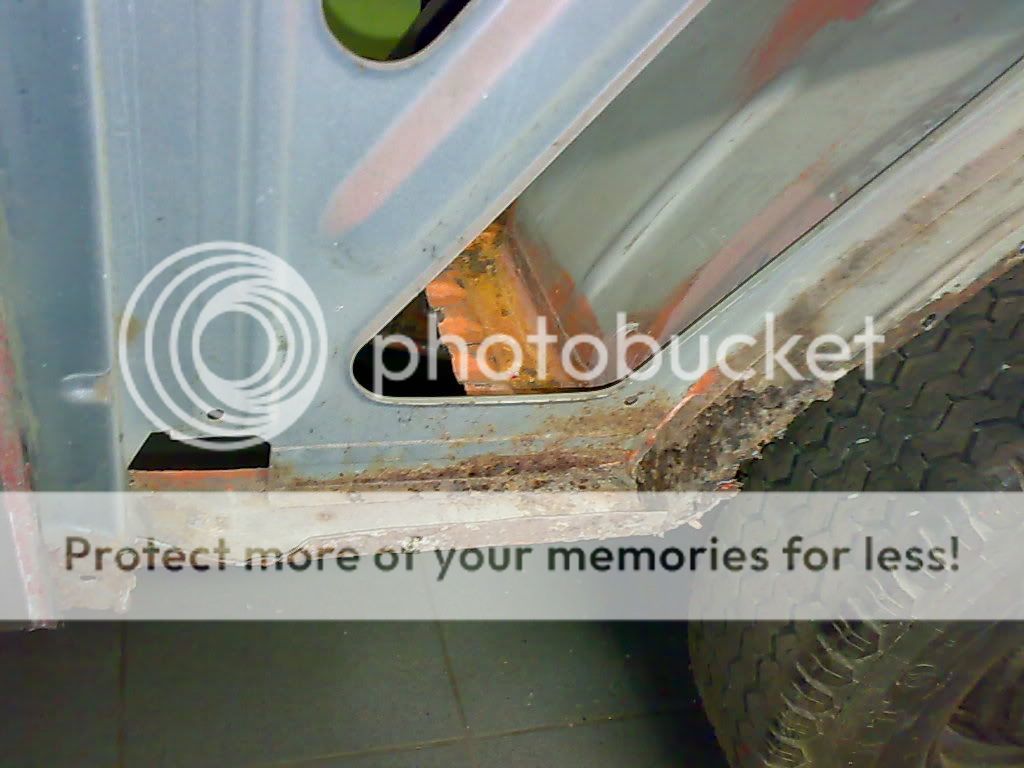

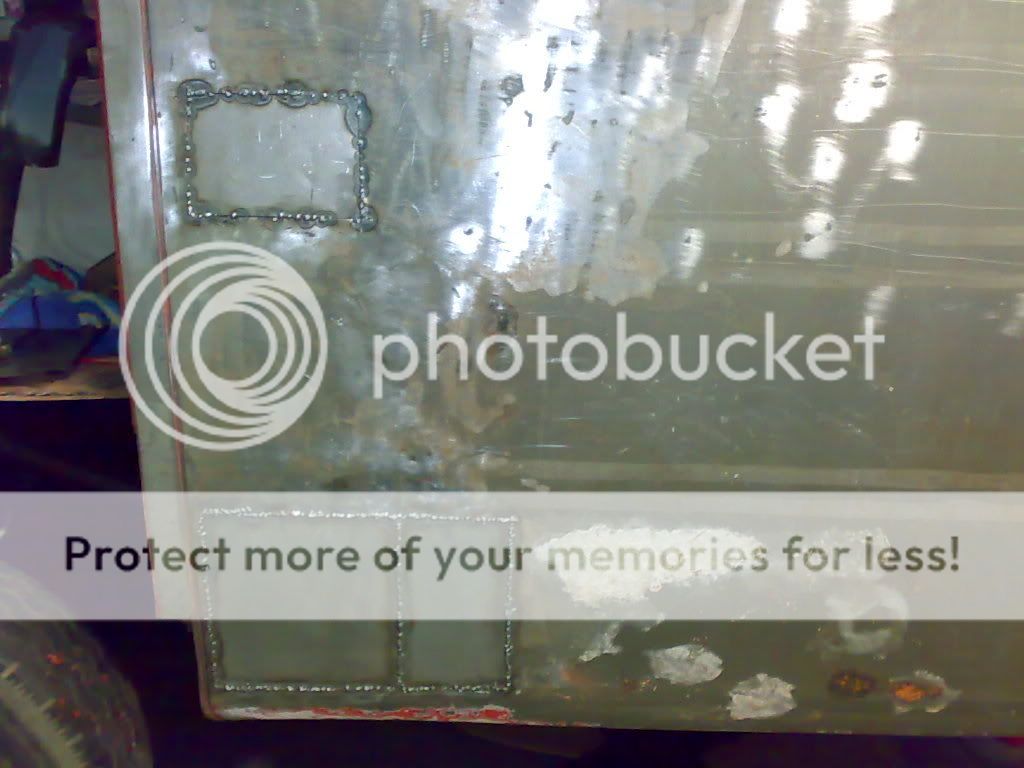

nice to see a nude bus

nice to see a nude bus

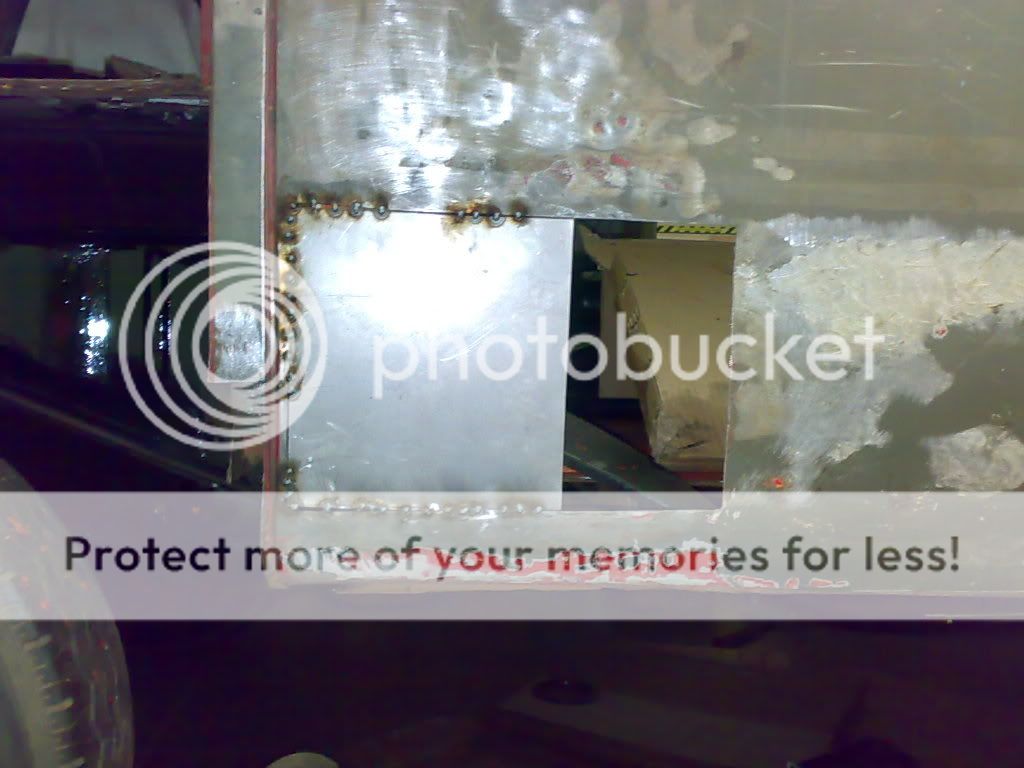

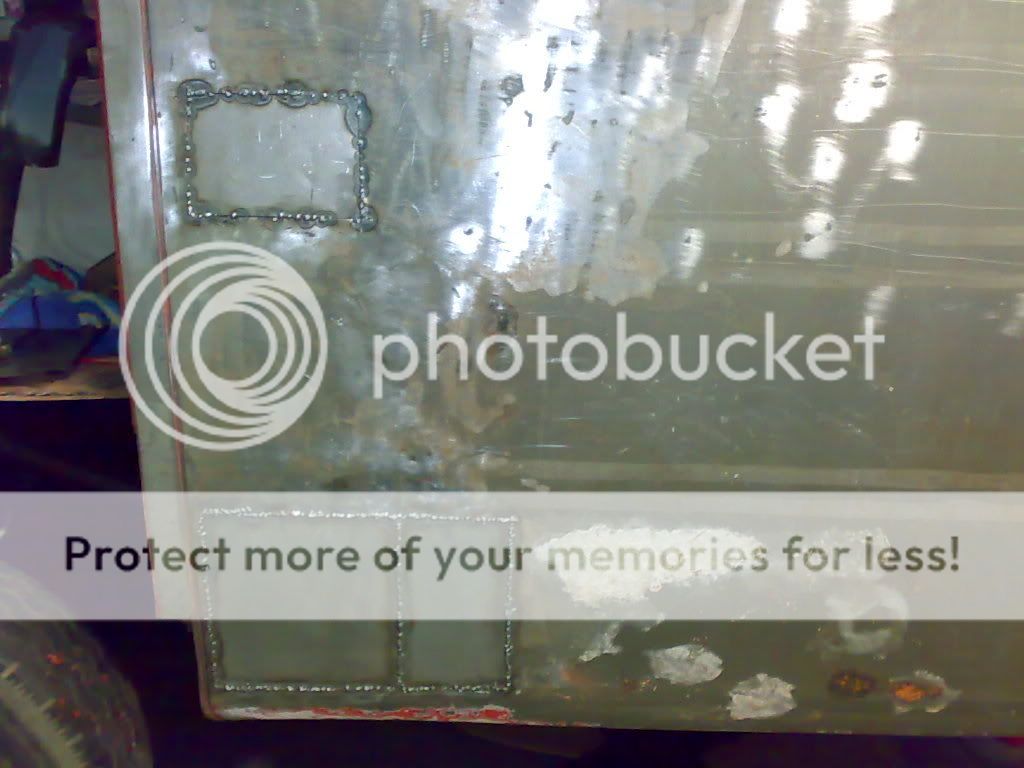

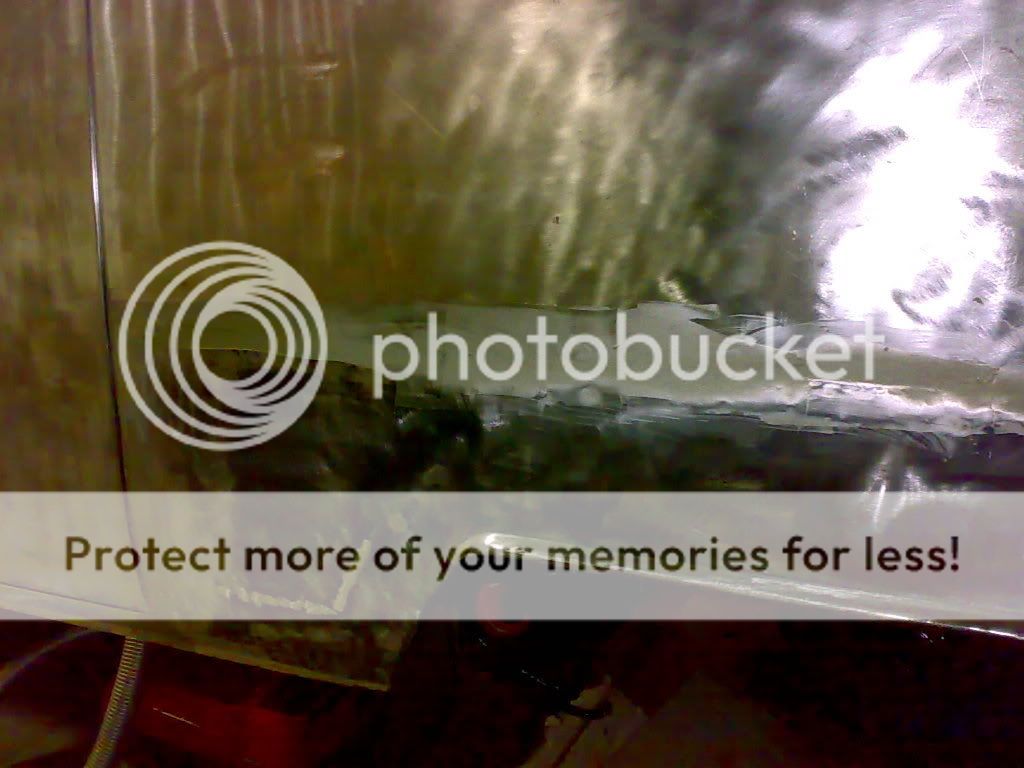

Nah, as it was only the bottom after the last crossmember, the engine compartment, wheel arches and whatever else is in that area I can't think of right nowJohnny said:nice work nate, was the media blast expensive?

Enter your email address to join: