mrknuckles

Active member

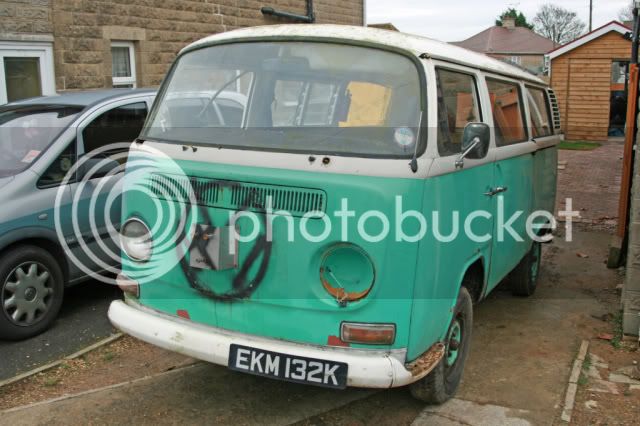

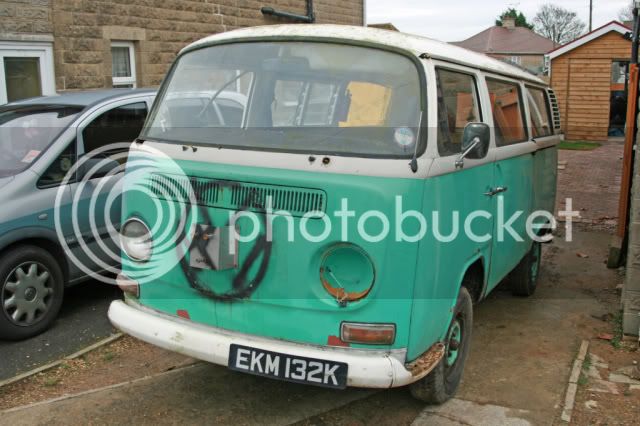

hi, introduced myself the other day and made a right balls up of everything! struggled to upload from photobucket then without realising it deleted it all so here goes again. Bought our '72 devon after deciding didnt want LHD, couldnt stretch to RHD import so only thing left was to try and reserect a uk RHD

the previous owners had used it as a donor vehicle taking everything except the rust!

started by removing the front wheelarch, good a place as any.

once arch removed started to get better idea of what i'd taken on

was going to be while before new arch was back on, next step-remove bellypans to start outrigger, jacking point and sill replacement. Still experementing with photobucket also

once jacking points cut away had to keep going until found something to weld to

this done front and rear the jack points could now go back on

before fitting inner sill had to make a reoair to the rear inner wheel arch where it joins sill

this done could now repair middle sill before continuing with front arch

maybe not! Bpost next then, after bracing A to B post, floor to roof, side to side and finally myself

this finally done just one more job before wheelarch can be fitted- the lower A post. Lokked at lots different shots of these on web trying to work out what should be there

and came up with this. My finest hour so far ha ha

when offering up new arch found the gap was not good, had a look around and saw how they were on new vans, nothing else for it, out came the trusty air cutter and off it came. Replaced the lower arch/ step with earlier step and this how it looks

the gap much more even, no beauty queen,but if you squint as i drive past(at dusk) should look ok

and this is the view inside the door ( S/H from fbivw) the step appears to line up ok with same clearance from inside door as other side . Thats about it for now currently sorting passengers front floor

and finally couldn't resist the reason for the strange name our bullie "knuckles" he's the one in the middle. Sorry to go on

the previous owners had used it as a donor vehicle taking everything except the rust!

started by removing the front wheelarch, good a place as any.

once arch removed started to get better idea of what i'd taken on

was going to be while before new arch was back on, next step-remove bellypans to start outrigger, jacking point and sill replacement. Still experementing with photobucket also

once jacking points cut away had to keep going until found something to weld to

this done front and rear the jack points could now go back on

before fitting inner sill had to make a reoair to the rear inner wheel arch where it joins sill

this done could now repair middle sill before continuing with front arch

maybe not! Bpost next then, after bracing A to B post, floor to roof, side to side and finally myself

this finally done just one more job before wheelarch can be fitted- the lower A post. Lokked at lots different shots of these on web trying to work out what should be there

and came up with this. My finest hour so far ha ha

when offering up new arch found the gap was not good, had a look around and saw how they were on new vans, nothing else for it, out came the trusty air cutter and off it came. Replaced the lower arch/ step with earlier step and this how it looks

the gap much more even, no beauty queen,but if you squint as i drive past(at dusk) should look ok

and this is the view inside the door ( S/H from fbivw) the step appears to line up ok with same clearance from inside door as other side . Thats about it for now currently sorting passengers front floor

and finally couldn't resist the reason for the strange name our bullie "knuckles" he's the one in the middle. Sorry to go on