Thanks for the comments guy's.

buddysbuddy said:

Looking good bud, and I reckon extra credits for all that chassis work being done on axle stands!!!!! :shock:

Cheers Buddysbuddy, it isn't always easy or pain free...

Wow, i can't believe it's been 9 days since i last put up a post. It feels like i havn't got much done in that time yet have only had 3 days away from the unit! I've hit one of those stages where you're constantly doing something but not really seeing any return! or that's how it feels.

Anyway what have i done in those past 9 days..

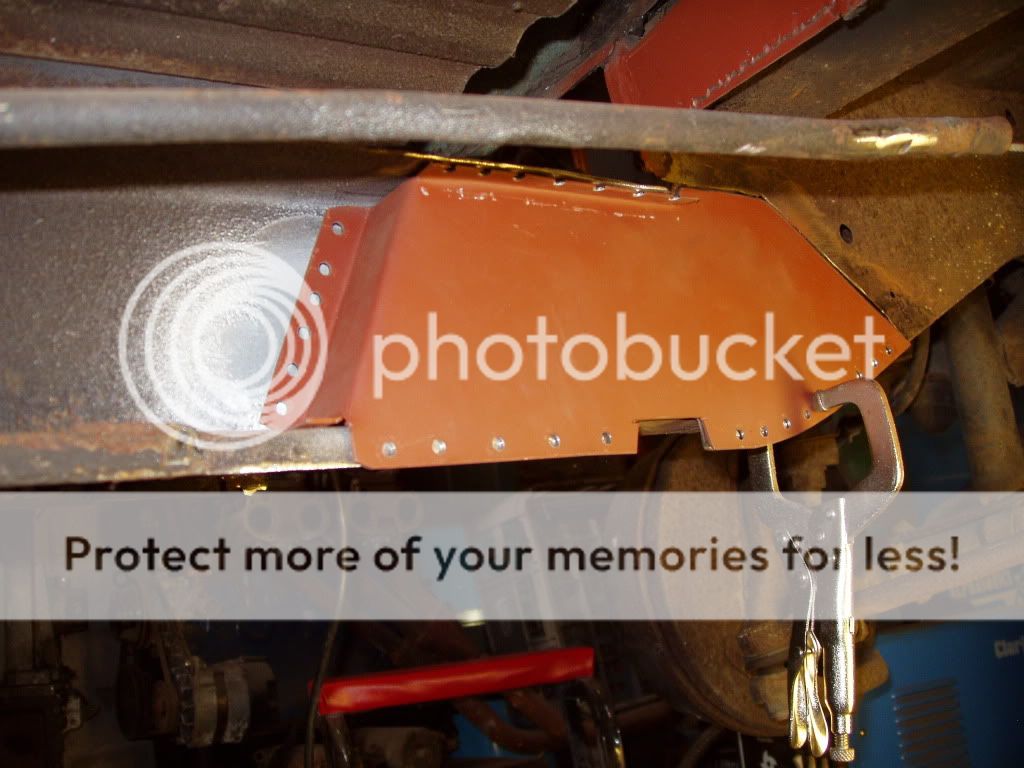

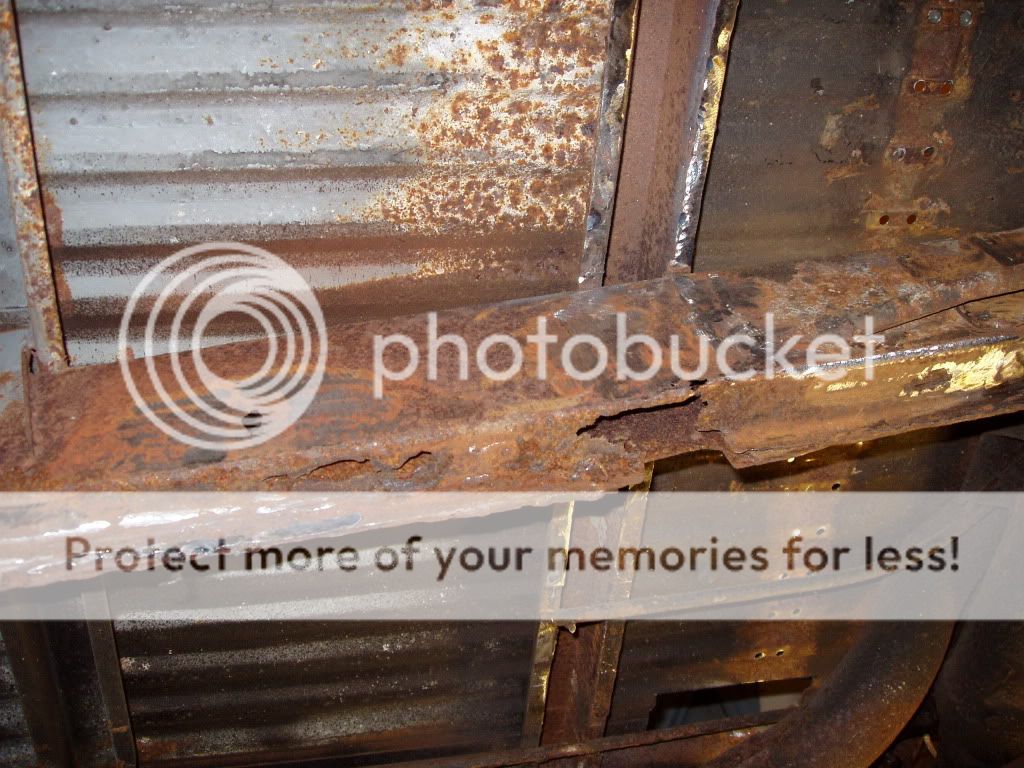

Cleaned all the chassis rails and repaired all rotton areas.

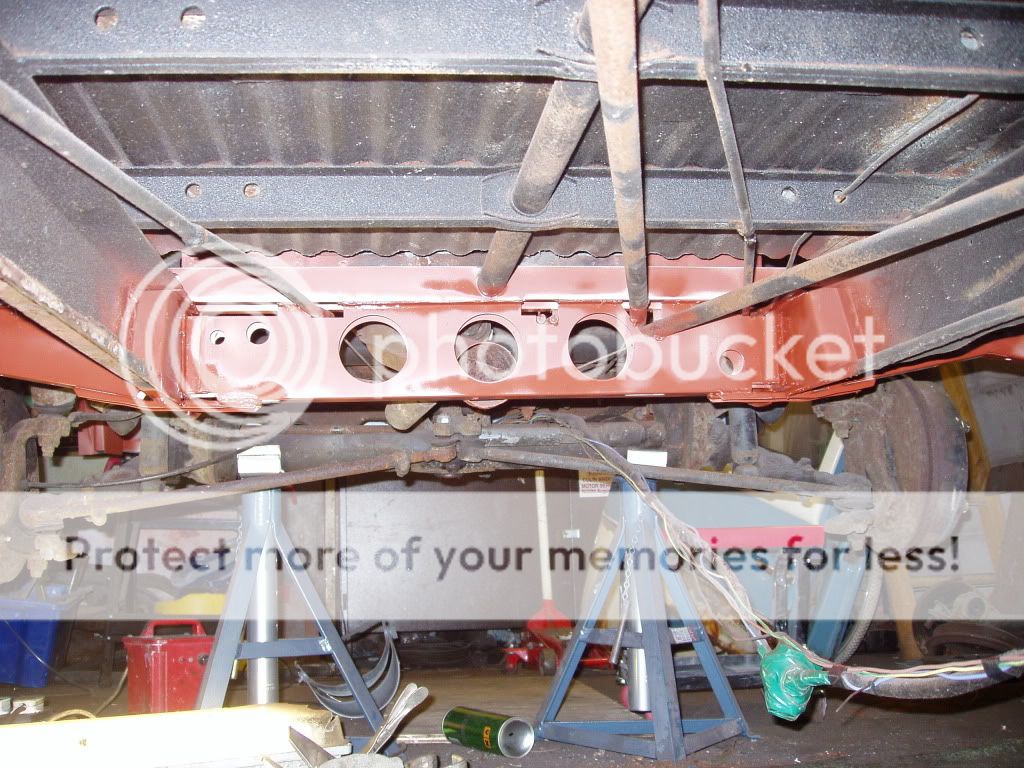

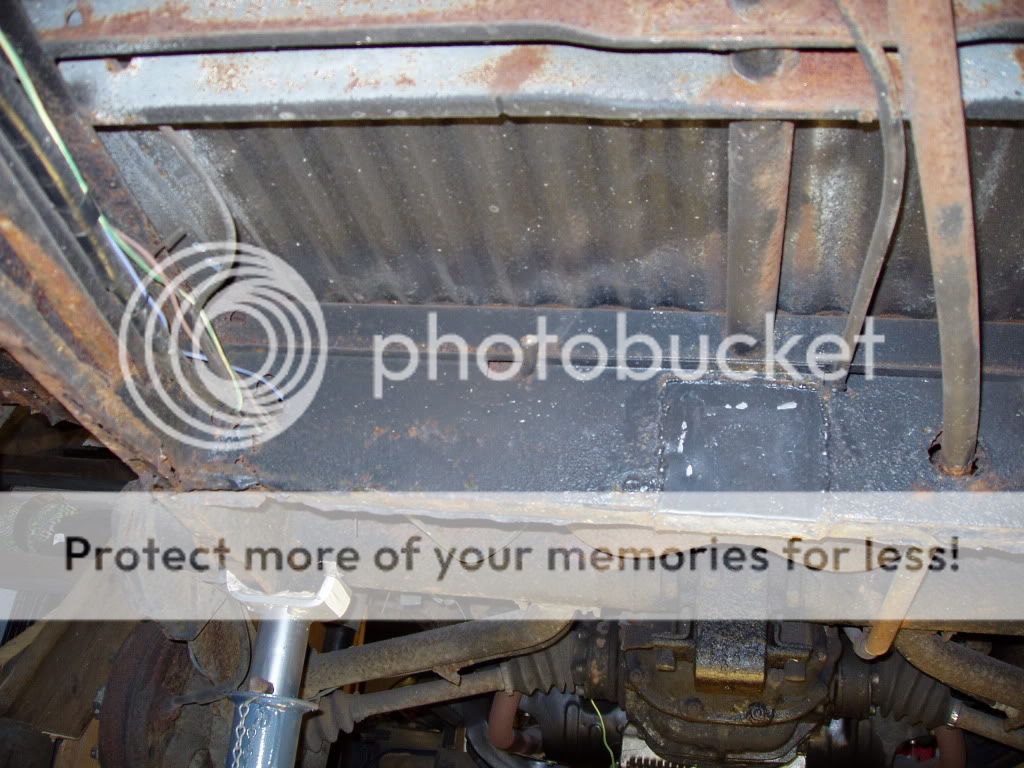

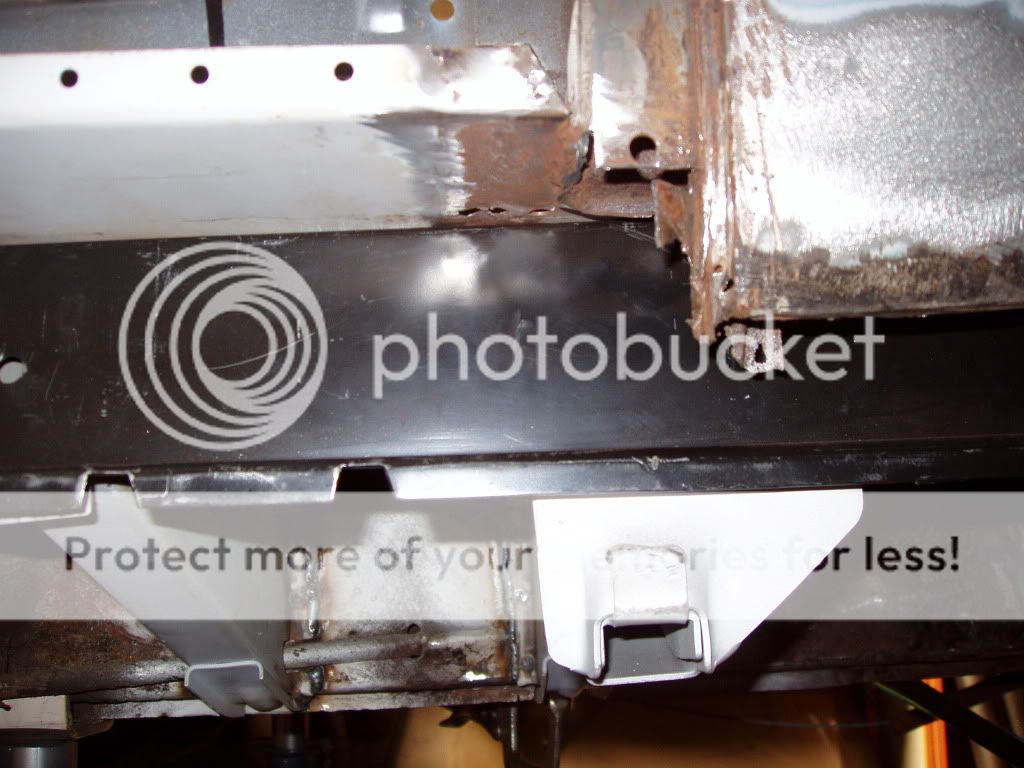

Rotary wire brushed the underside of the rear floor ready to fit the new top hat sections.

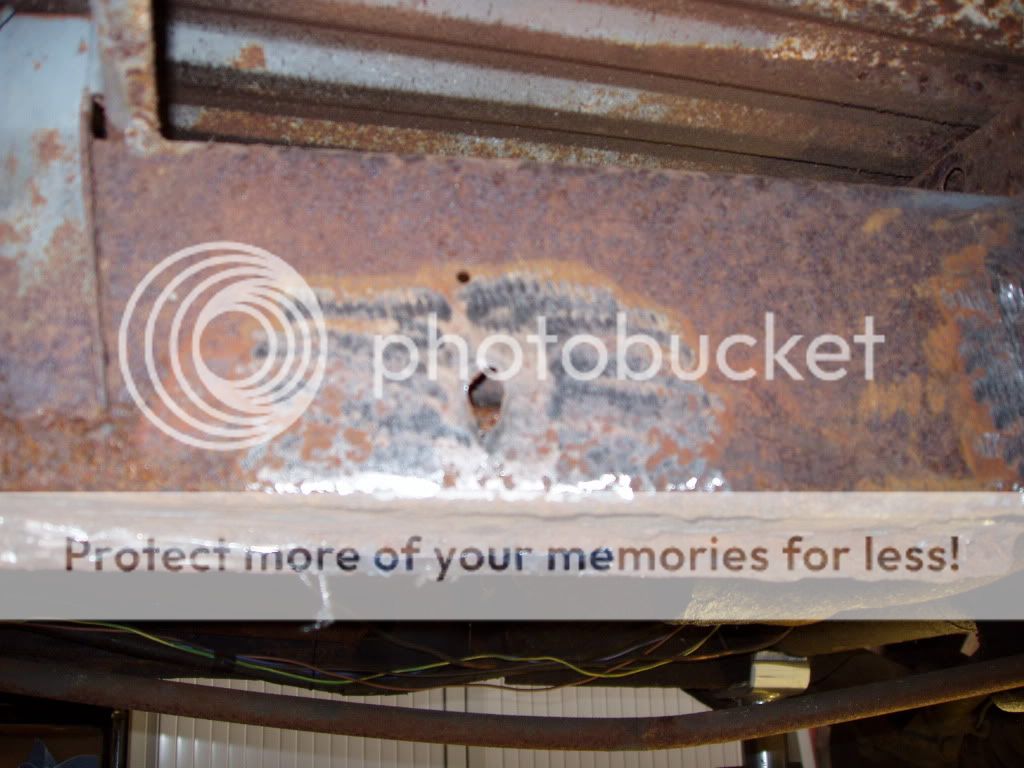

Removed some rotton floor section in the rear corners where they meet the rear arches. Cut out the rotton area of the inner rear wheel tub front closing panel ready for new metal.

The section of floor removed above the chassis was to gain access for a repair on top of the chassis.

Cut out some of the rear arch to give better access to the rear floor and inner arch area and position the new rear most top hat section.

Made and fitted new rear floor sections.

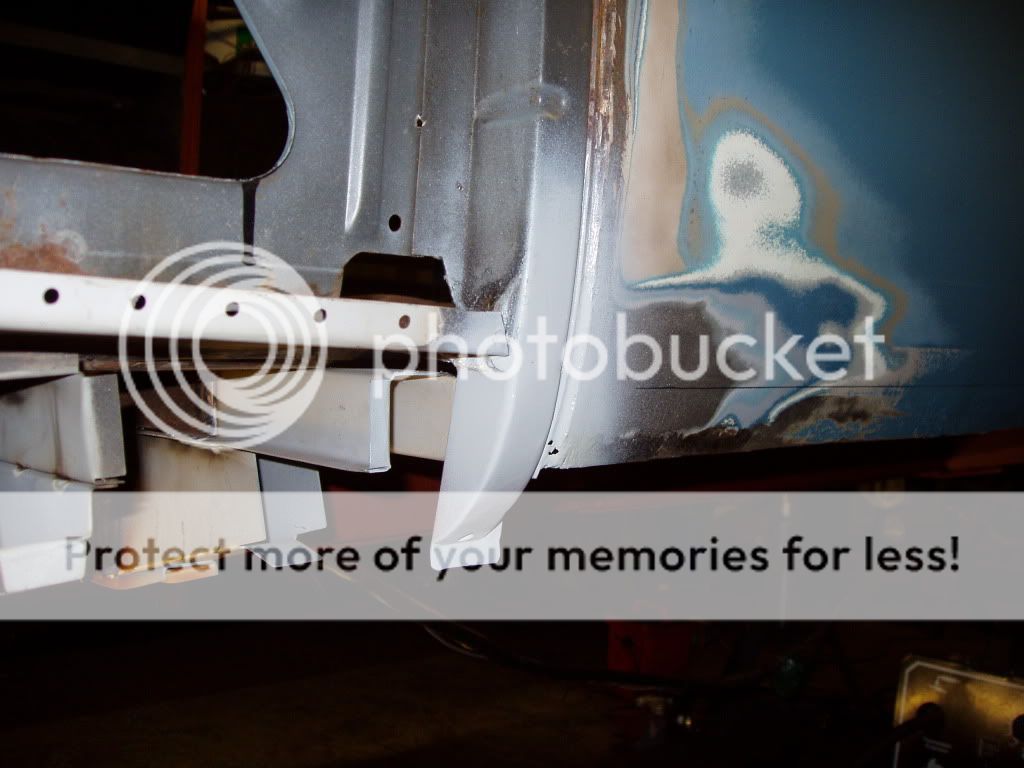

New inner wheel tub front closing panel checked with new floor section.

Measured and marked a new piece ready to be made for the bottom of the middle panel to accept the new outer sill (the previous bodger cut the lip off that the new sill welds to).

Next thing is to check the alignment of the new outriggers and top hat sections against the new inner sill!