Darrencambs

Well-known member

- Joined

- Nov 14, 2010

- Messages

- 76

- Reaction score

- 0

Well. Here I am again with another thread revival. Last year's rivival stalled around October with far too many things going on - including getting married on Christmas Eve. Middi (Dave) from Earlybay.com kindly provided transport for the bride and her brother. Here's a quick pic of Nikki and her brother, Liam, arriving.

Our wedding present list comprised solely of JK vouchers, so those have been spent on new floor panels, rear brake back plates, n/s rear wheel arch tub and various other panels, and I've now finally resolved to get cracking on the bus again, so we're good to go for another welding frenzy.

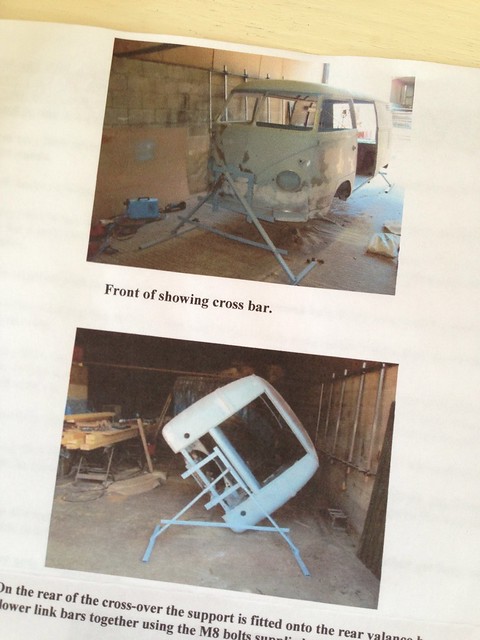

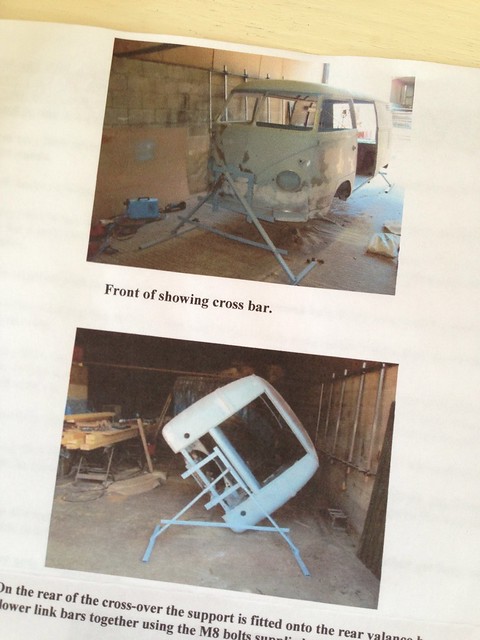

I mentioned in my previous post that I'd bee thinking of buying a roll-over jig. I picked that up a week or so ago, so now faced with the challeng of turning this pile of steel and nuts and bolts...

...into something that looks like this:

Although the jig looks a bit lightweight, I'm happy that will be OK for rolling the bus over. What I'm not confident about is the way it mounts to the bus - particularly at the back end where it's just designed to use the rear valance bolts. So this weekend I knocked up another bracket that extends round to the engine mounting brackets. Needs a bit of beefing up still with some webs, but it should hold when I roll it over.

Got the gearbox out which has been suspended from a rope round a block of wood in the engine bay ever since we've had the bus. Crusty on the top and caked in grease underneath. The allen bolts in the CV joints were mostly seized so I had to grind a number of them off.

Then jacked up the rear end and onto axle stands ready to strip off the rest of the rear suspension.

Gave the torsion bar and suspension plate a quick skim with the grinder so I can align it properly when it comes to putting it all back together again:

The rest of the day has been spent wrestling with those bloody great bolts holding the swing-arms to the rear hub carrier. Despite cleaning the threads and soaking with penetrating oil they have been very reluctant to budge even with a 3 foot breaker bar. Managed to get the near-side done though, and half way there now with the off-side.

Hopefully next weekend I'll have everything off the rear end and will have dropped the front beam off too. Probably have to beef up the front bracket for the roll-over jig, but if all goes well, Bunty should be enjoying a spit-roast this time next week!

Our wedding present list comprised solely of JK vouchers, so those have been spent on new floor panels, rear brake back plates, n/s rear wheel arch tub and various other panels, and I've now finally resolved to get cracking on the bus again, so we're good to go for another welding frenzy.

I mentioned in my previous post that I'd bee thinking of buying a roll-over jig. I picked that up a week or so ago, so now faced with the challeng of turning this pile of steel and nuts and bolts...

...into something that looks like this:

Although the jig looks a bit lightweight, I'm happy that will be OK for rolling the bus over. What I'm not confident about is the way it mounts to the bus - particularly at the back end where it's just designed to use the rear valance bolts. So this weekend I knocked up another bracket that extends round to the engine mounting brackets. Needs a bit of beefing up still with some webs, but it should hold when I roll it over.

Got the gearbox out which has been suspended from a rope round a block of wood in the engine bay ever since we've had the bus. Crusty on the top and caked in grease underneath. The allen bolts in the CV joints were mostly seized so I had to grind a number of them off.

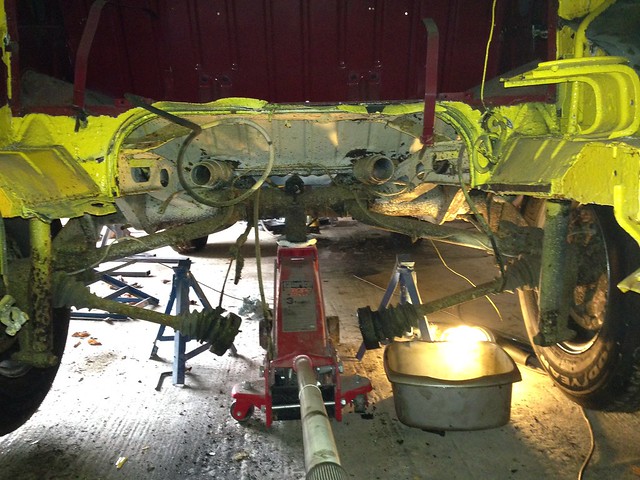

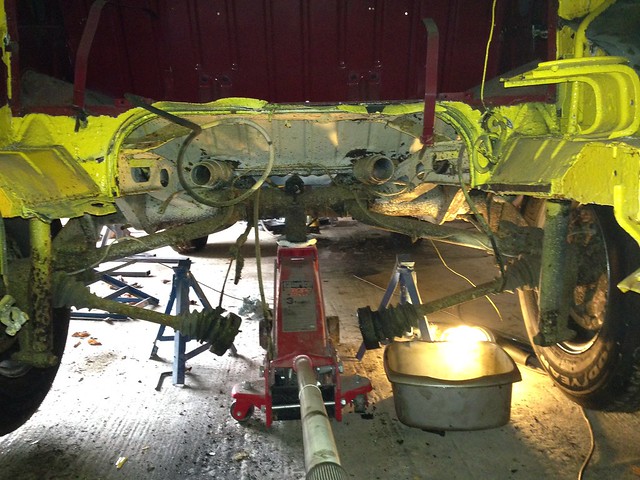

Then jacked up the rear end and onto axle stands ready to strip off the rest of the rear suspension.

Gave the torsion bar and suspension plate a quick skim with the grinder so I can align it properly when it comes to putting it all back together again:

The rest of the day has been spent wrestling with those bloody great bolts holding the swing-arms to the rear hub carrier. Despite cleaning the threads and soaking with penetrating oil they have been very reluctant to budge even with a 3 foot breaker bar. Managed to get the near-side done though, and half way there now with the off-side.

Hopefully next weekend I'll have everything off the rear end and will have dropped the front beam off too. Probably have to beef up the front bracket for the roll-over jig, but if all goes well, Bunty should be enjoying a spit-roast this time next week!