Hi EarlyBay,

After owning my bus for a year now I thought it was about time I got a thread going over her progress. Late 2020 I bought a crossover bay looking a little worse for wear with the idea of converting it to electric. I know you have all probably seen electric conversions done before but me being me, this wasn't ever going to be to your standard ev conversion and so hopefully some of you will find this at least somewhat interesting.

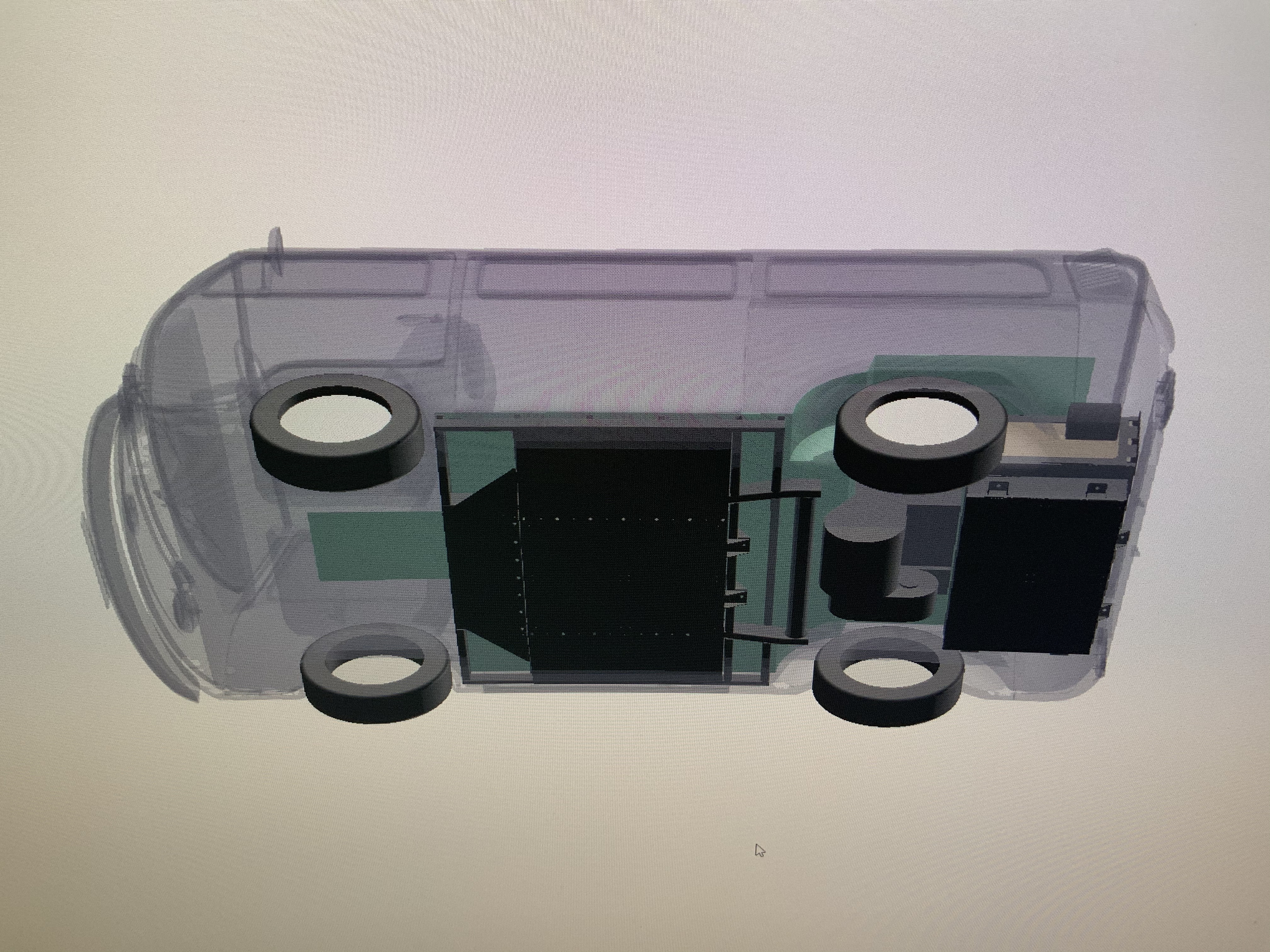

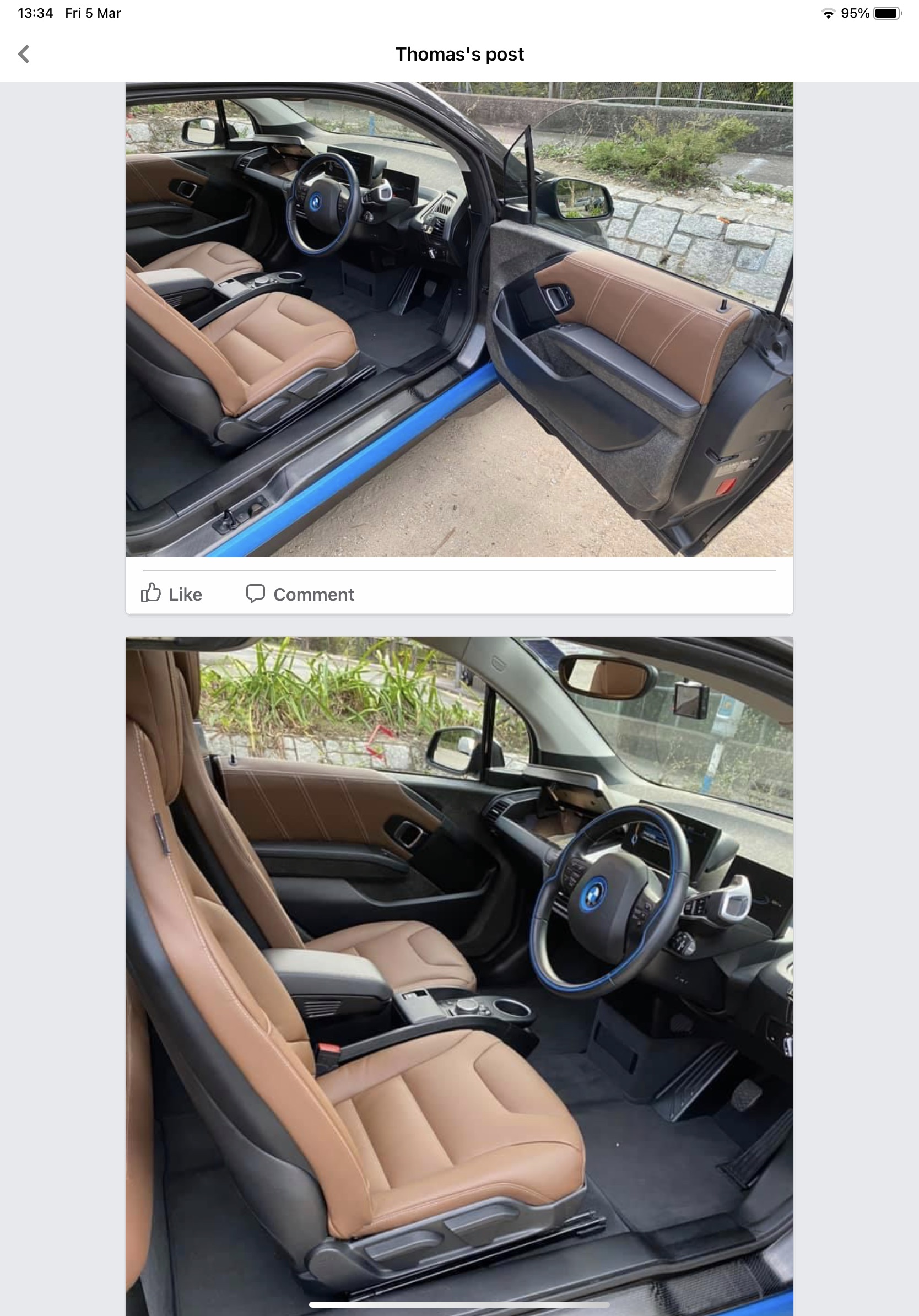

The grand plan is to 'transplant' the running gear from a 2019 BMW i3 into the camper, resulting in a mid-'engined' 170bhp bus which should have a driving range of around 140 miles. The batteries will be placed under the bus (between the chassis rails under the floor) and in the engine bay, whilst the motor will sit in place of the gearbox just in front of the rear wheel line.

*Disclaimer* As of December 2021 the bus is nowhere near complete and so I will be going over what I got done this last year (mainly body work and paint) but I have started to get into the conversion side of things in the past few weeks. You will have to bear with me as this project is a slow burner , but this year I should have some more time to spend on getting her finished (famous last words and all that).

So here she was when I bought her back in 2020, the previous owner had decided to paint it on his drive in what he called 'Audi Nardo Grey' except for some reason had given up half way through, leaving a patchy and waxy finish which was obviously gonna have to go.

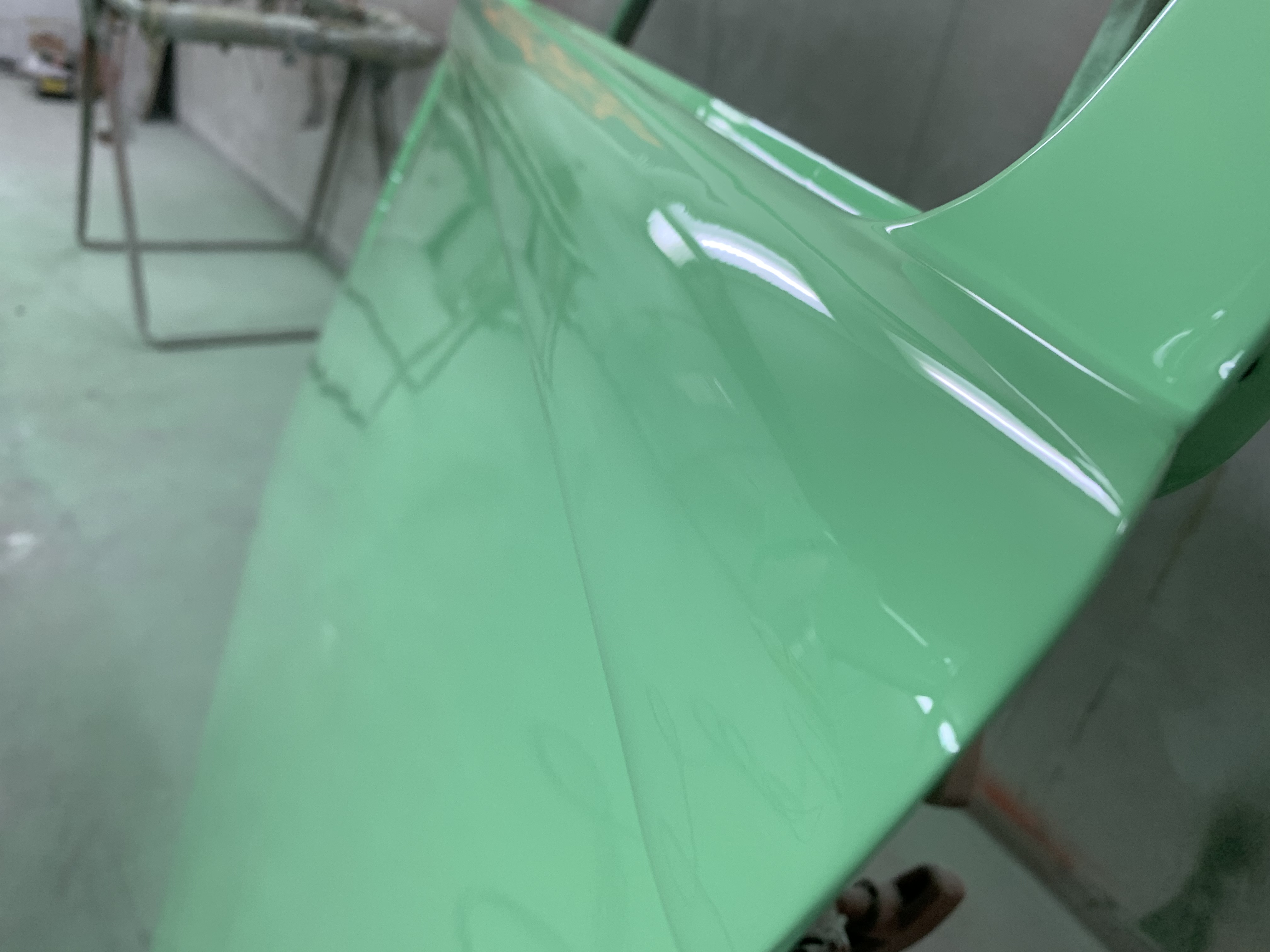

After getting her inside and starting to strip her down, I managed to sell the engine and gearbox and few other pieces over the winter and then went about tackling that paint job before getting into the resto any further.

I am gathering together some photos of the work done so far and so I will be slowly adding them to thread. Obviously I am looking back at work that has already been done for now, but I imagine that I will soon catch back up with myself and then progress will seem a little slower!

Thanks,

Nick

After owning my bus for a year now I thought it was about time I got a thread going over her progress. Late 2020 I bought a crossover bay looking a little worse for wear with the idea of converting it to electric. I know you have all probably seen electric conversions done before but me being me, this wasn't ever going to be to your standard ev conversion and so hopefully some of you will find this at least somewhat interesting.

The grand plan is to 'transplant' the running gear from a 2019 BMW i3 into the camper, resulting in a mid-'engined' 170bhp bus which should have a driving range of around 140 miles. The batteries will be placed under the bus (between the chassis rails under the floor) and in the engine bay, whilst the motor will sit in place of the gearbox just in front of the rear wheel line.

*Disclaimer* As of December 2021 the bus is nowhere near complete and so I will be going over what I got done this last year (mainly body work and paint) but I have started to get into the conversion side of things in the past few weeks. You will have to bear with me as this project is a slow burner , but this year I should have some more time to spend on getting her finished (famous last words and all that).

So here she was when I bought her back in 2020, the previous owner had decided to paint it on his drive in what he called 'Audi Nardo Grey' except for some reason had given up half way through, leaving a patchy and waxy finish which was obviously gonna have to go.

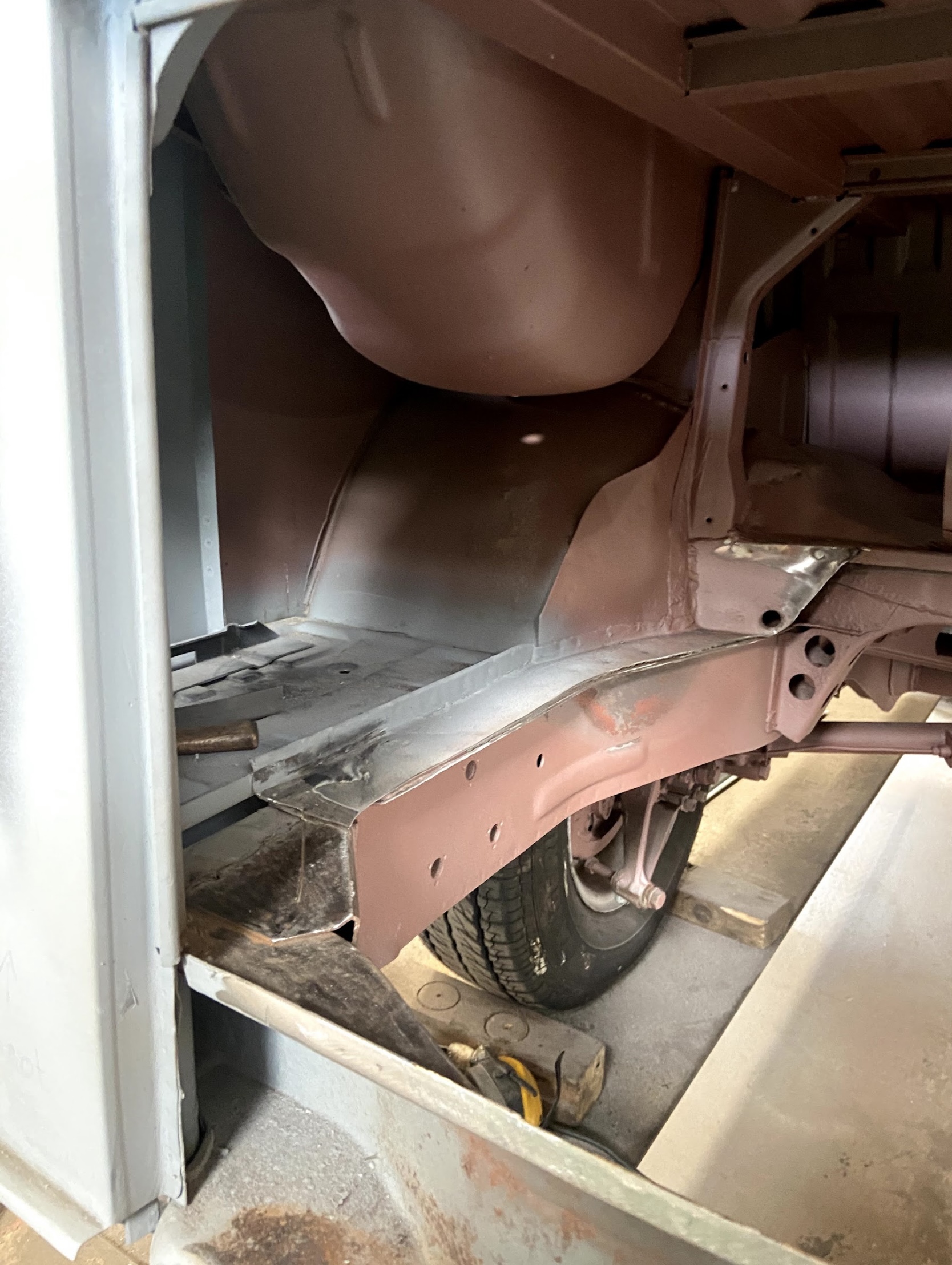

After getting her inside and starting to strip her down, I managed to sell the engine and gearbox and few other pieces over the winter and then went about tackling that paint job before getting into the resto any further.

I am gathering together some photos of the work done so far and so I will be slowly adding them to thread. Obviously I am looking back at work that has already been done for now, but I imagine that I will soon catch back up with myself and then progress will seem a little slower!

Thanks,

Nick