cunning plan

Well-known member

- Joined

- Jul 15, 2008

- Messages

- 2,625

- Reaction score

- 1

- Location

- Northamptonshire

- Year of Your Van(s)

- 1968

- Van Type

- Clipper / Microbus

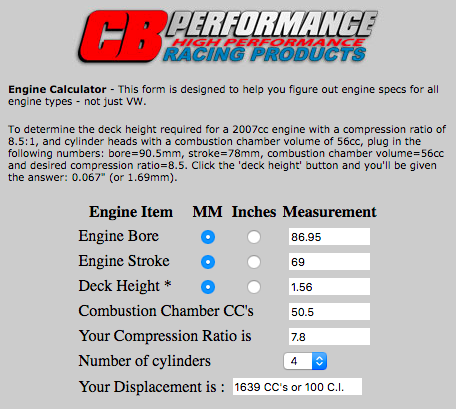

So I have measured deck height and I have values of:

Cylinder 1: Deck Height: 1.86mm - Compression Ratio: 7.7:1

Cylinder 2: Deck Height: 1.85mm - Compression Ratio: 7.7:1

Cylinder 3: Deck Height: 1.85mm - Compression Ratio: 7.7:1

Cylinder 4: Deck Height: 2.01mm - Compression Ratio: 7.6:1

So Cylinder 4 seems to be the odd one with 2.01mm and a 7.6:1 compression ratio.

Two questions.

Firstly, I want this engine to be a little lazy and not over-stressed as I want to try and make it as reliable as possible. So I was thinking of running below 7.5:1 compression, perhaps 7:2/7:3.

Is this too low, should I aim for 7.5 or leave it at 7.7, or is 7.7 too high?

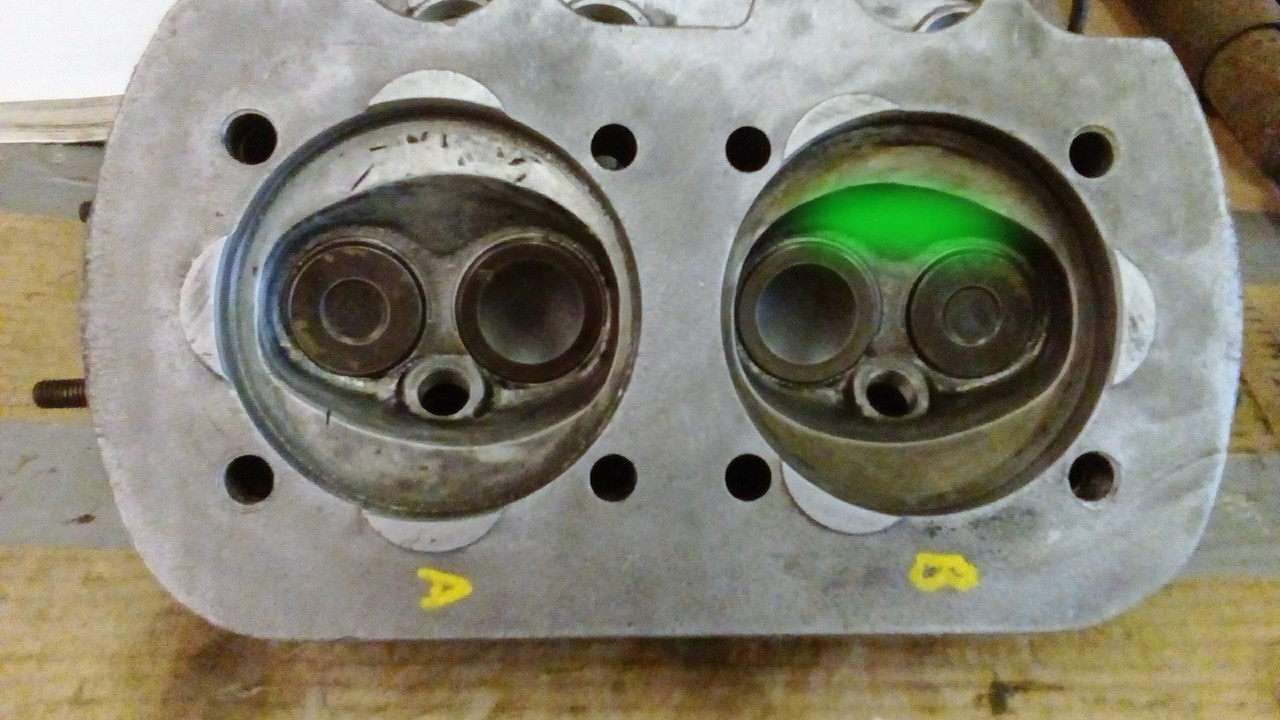

Second question, is the difference in Cylinder 4 a big problem? I presume you would want them all to be as close as possible? I am using an old case with an unknown history to build this engine and a new AA 1641 kit.

If it is a problem, is it just a case of adding deck height using shims to the other three cylinders to match cylinder 4 - which seems sensible if I want to lower the compression ratio anyway, I certainly do not want to go higher, so hopefully no machining is involved to cut the case on cylinder 4 to match the other 3?

What do you all think?

:?: :roll: :| :| :|

:roll: :| :| :|

:sign0009:

Engine Specs:

All stock 1600 parts except:

1641 Barrels and pistons

Twin 40 IDFs

Electronic Ignition

Cylinder 1: Deck Height: 1.86mm - Compression Ratio: 7.7:1

Cylinder 2: Deck Height: 1.85mm - Compression Ratio: 7.7:1

Cylinder 3: Deck Height: 1.85mm - Compression Ratio: 7.7:1

Cylinder 4: Deck Height: 2.01mm - Compression Ratio: 7.6:1

So Cylinder 4 seems to be the odd one with 2.01mm and a 7.6:1 compression ratio.

Two questions.

Firstly, I want this engine to be a little lazy and not over-stressed as I want to try and make it as reliable as possible. So I was thinking of running below 7.5:1 compression, perhaps 7:2/7:3.

Is this too low, should I aim for 7.5 or leave it at 7.7, or is 7.7 too high?

Second question, is the difference in Cylinder 4 a big problem? I presume you would want them all to be as close as possible? I am using an old case with an unknown history to build this engine and a new AA 1641 kit.

If it is a problem, is it just a case of adding deck height using shims to the other three cylinders to match cylinder 4 - which seems sensible if I want to lower the compression ratio anyway, I certainly do not want to go higher, so hopefully no machining is involved to cut the case on cylinder 4 to match the other 3?

What do you all think?

:?:

:sign0009:

Engine Specs:

All stock 1600 parts except:

1641 Barrels and pistons

Twin 40 IDFs

Electronic Ignition