Zcat7

Well-known member

- Joined

- Apr 12, 2010

- Messages

- 662

- Reaction score

- 3

- Location

- Oxfordshire

- Year of Your Van(s)

- 1972

- Van Type

- Crossover

I fitted an electric fuel pump this weekend but before getting stuck in I came up with a wiring configuration to give me a dedicated fused supply through a relay which protects against the engine stopping/stalling (and leaving the pump running) by using the oil pressure switch. Like the best laid plans it relied upon the oil pressure switch being "normally open" and putting an earth on when it gets pressure. This turned out not to be the case; it was in fact "normally closed" and removed the earth when pressured up...

Anyway, it wasn't the end of the world but ultimately it has resulted in me using an ignition switched +ve supply from the coil to both power the relay and supply the pump. I have fused the supply at 5 amps so I don't think I'm putting to much strain on the circuit but I wondered if anyone could see any problem with loading the coil feed further?

It all works OK, cuts out if the oil pressure fails etc but I thought I'd seek a sanity check! If necessary I have found an oil pressure switch that has both NC and NO connections on it but I'm unsure if it has the correct thread and would need to make an adaptor if not. I would be happy to leave as is if you auto elecs think it's OK as is.

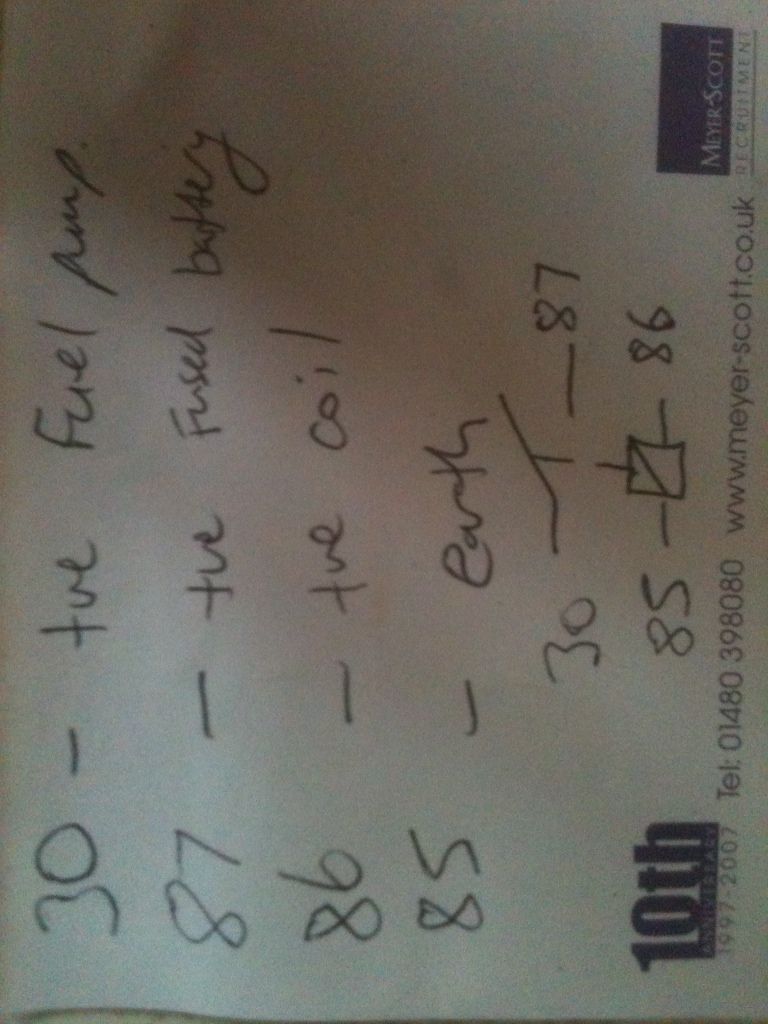

Wiring as follows -

85 - Switched +ve from coil

86 - Earth from oil pressure switch (NC)

87A (NC) - Switched +ve from coil

30 - Feed to fuel pump

So basically if the engine stalls or I get oil pressure failure it will cut the pump by activating the relay and switching to an open terminal (87).

I've also put a manual switch in to prime the pump in case I have trouble starting (as the pump won't run until the engine has generated enough oil pressure) or the bus has stood for a while. This just piggy backs on to terminal 30.

Neil

Anyway, it wasn't the end of the world but ultimately it has resulted in me using an ignition switched +ve supply from the coil to both power the relay and supply the pump. I have fused the supply at 5 amps so I don't think I'm putting to much strain on the circuit but I wondered if anyone could see any problem with loading the coil feed further?

It all works OK, cuts out if the oil pressure fails etc but I thought I'd seek a sanity check! If necessary I have found an oil pressure switch that has both NC and NO connections on it but I'm unsure if it has the correct thread and would need to make an adaptor if not. I would be happy to leave as is if you auto elecs think it's OK as is.

Wiring as follows -

85 - Switched +ve from coil

86 - Earth from oil pressure switch (NC)

87A (NC) - Switched +ve from coil

30 - Feed to fuel pump

So basically if the engine stalls or I get oil pressure failure it will cut the pump by activating the relay and switching to an open terminal (87).

I've also put a manual switch in to prime the pump in case I have trouble starting (as the pump won't run until the engine has generated enough oil pressure) or the bus has stood for a while. This just piggy backs on to terminal 30.

Neil