Ok guys, as you may know I have been tinkering with heads over the past little while to try and make sense of what is needed for a bus vs what is available on the market. The following are my findings based upon my measurements with my home made flow bench with my modifications. It is valid for the heads I measured and modified and will apply to the majority of after market heads out there.

So here we go.

What does a bus engine need to deliver? In simple terms the vast majority of owners are looking for an engine that will pull cleanly, drag a fully loaded bus up hills and cruise along at 60 - 70 all day long.

In reality this equates to torque in an engine, the ability to pull you, your family and all the gear up hills without having to drop down to second gear.

How to you maximise torque? Well this is by getting the maximum fuel/air mixture into the cylinder across all revs, or in engine terms, maximising volumetric efficiency.

How do you go about achieving this?

Add a supercharger (including turbo) or for NA you need to maximise airflow into the cylinder.

How do you maximise inlet airflow?

Just stick big valve heads on ! - well not really. As you can see from the following, just upping the valve sizes can be detrimental as you run into shrouding issues, especially at low lift.

This plot shows a stock 043 head vs an AA 40x35.5 head (both standard bore).

Things look pretty impressive until you analyse the curve, here you will see that the big valve head actually flows LESS than the 043 at low valve lift.

You may say that this does not matter as the high lift gains are big. In a bug or a racer then this is fine, but a bus is going to be terrible to drive. Also remember that the average valve lift is a lot less than your max lift which I will come on to later.

If we take the 043s and modify them we can get a pretty decent result as seen below:

This shows a stock 043 that has had a decent valve job and some flowing of the intake ports.

A very important goal to remember at this stage is that at low rpm, the gas speed drops off, which kills the volumetric efficiency. For a torquey bus motor, you need the highest gas speed at low RPM. It is no good having all your torque over 4000rpm, you would go through clutch plates like nobodies business. The key to gas speed is port area, if you make the ports big to get high flow, you kill the gas speed at low rpm.

The vast majority of after market heads are basically over ported for a bus application. Big valves and big ports needs big revs to make them work.

So how do we maximise the flow, keep gas speed for the best response in a bus.

I looked at the "big valve" head and noticed that there were some significant gains to be made without having to open up the ports.

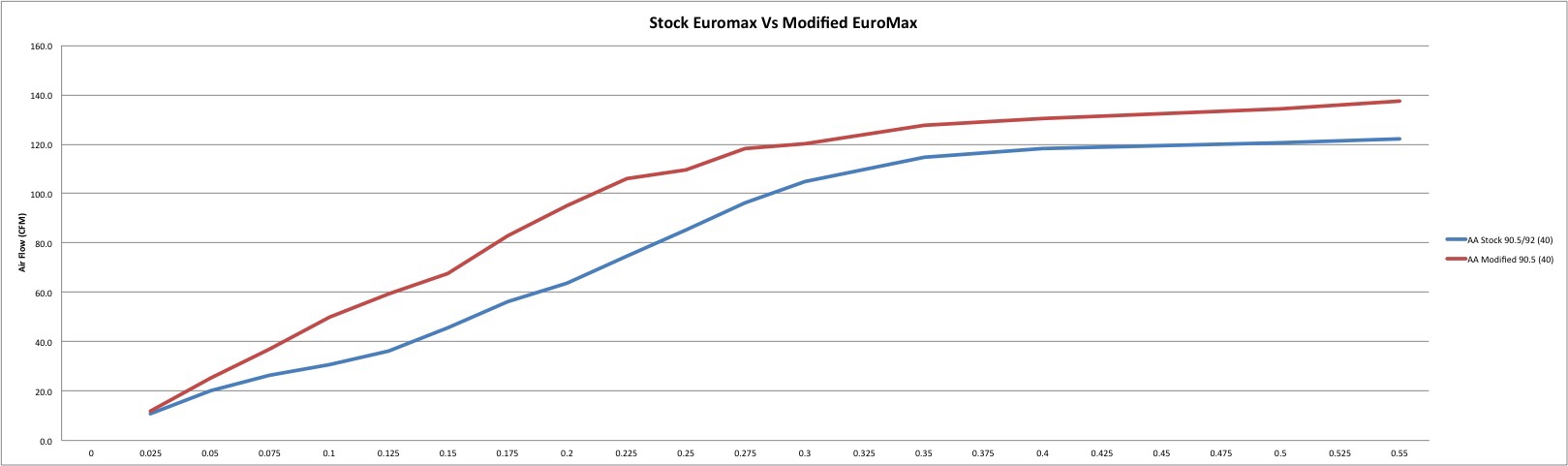

With some un-shrouding of the valve, 3 angled seat, valve reshape and minor flow work we can actually get some decent results.

Now remember what I said about cam lift earlier. The important factor to remember is the average cam lift, not just the max lift or duration. This gives the effective lift of the cam and when you play this against the flow of the head you can see that having a big cam in a stock head will not make much power difference, similarly, a stock cam in a good head is not the best use of your cash either.

So my conclusions are that to get the best from a bus engine, you need to balance flow for gas speed and select a cam that gives you a decent average lift but with short overlap. Stock big valve heads are inherently not the best for a bus motor.

If anyone has some other big valve heads they are willing to loan me I would be very interested to put them on my flow bench and see what they can really do.

Cheers,

Jon

Sent from my GX64 SatCom phone using Tapatalk

So here we go.

What does a bus engine need to deliver? In simple terms the vast majority of owners are looking for an engine that will pull cleanly, drag a fully loaded bus up hills and cruise along at 60 - 70 all day long.

In reality this equates to torque in an engine, the ability to pull you, your family and all the gear up hills without having to drop down to second gear.

How to you maximise torque? Well this is by getting the maximum fuel/air mixture into the cylinder across all revs, or in engine terms, maximising volumetric efficiency.

How do you go about achieving this?

Add a supercharger (including turbo) or for NA you need to maximise airflow into the cylinder.

How do you maximise inlet airflow?

Just stick big valve heads on ! - well not really. As you can see from the following, just upping the valve sizes can be detrimental as you run into shrouding issues, especially at low lift.

This plot shows a stock 043 head vs an AA 40x35.5 head (both standard bore).

Things look pretty impressive until you analyse the curve, here you will see that the big valve head actually flows LESS than the 043 at low valve lift.

You may say that this does not matter as the high lift gains are big. In a bug or a racer then this is fine, but a bus is going to be terrible to drive. Also remember that the average valve lift is a lot less than your max lift which I will come on to later.

If we take the 043s and modify them we can get a pretty decent result as seen below:

This shows a stock 043 that has had a decent valve job and some flowing of the intake ports.

A very important goal to remember at this stage is that at low rpm, the gas speed drops off, which kills the volumetric efficiency. For a torquey bus motor, you need the highest gas speed at low RPM. It is no good having all your torque over 4000rpm, you would go through clutch plates like nobodies business. The key to gas speed is port area, if you make the ports big to get high flow, you kill the gas speed at low rpm.

The vast majority of after market heads are basically over ported for a bus application. Big valves and big ports needs big revs to make them work.

So how do we maximise the flow, keep gas speed for the best response in a bus.

I looked at the "big valve" head and noticed that there were some significant gains to be made without having to open up the ports.

With some un-shrouding of the valve, 3 angled seat, valve reshape and minor flow work we can actually get some decent results.

Now remember what I said about cam lift earlier. The important factor to remember is the average cam lift, not just the max lift or duration. This gives the effective lift of the cam and when you play this against the flow of the head you can see that having a big cam in a stock head will not make much power difference, similarly, a stock cam in a good head is not the best use of your cash either.

So my conclusions are that to get the best from a bus engine, you need to balance flow for gas speed and select a cam that gives you a decent average lift but with short overlap. Stock big valve heads are inherently not the best for a bus motor.

If anyone has some other big valve heads they are willing to loan me I would be very interested to put them on my flow bench and see what they can really do.

Cheers,

Jon

Sent from my GX64 SatCom phone using Tapatalk