cheers johnny. they looked at me very odd when i got on the plane with a 165 45 15 tyre as hand luggage as only one of them fitted in my suit case. :roll:

on the van i have hit a bit of a wall, a shortage of ready cash means that i have no play money for the van and since my bonus at work came in £1.5 light things are a going to be a bit slow till i get the vans spray money back together.

as my bus had rotted away everywhere, the accelerator linkage was useless. after having a look at what repair kits there are about for them i decided to have a go at improving on the original theme.

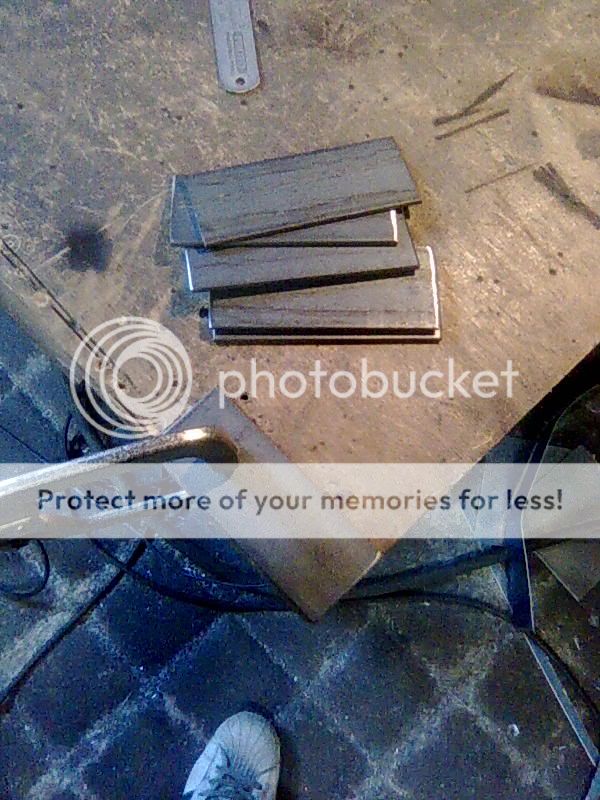

used a bit of large 10mm thick angle iron i had around and made a little l shape

drilled 10mm and 6mm holes

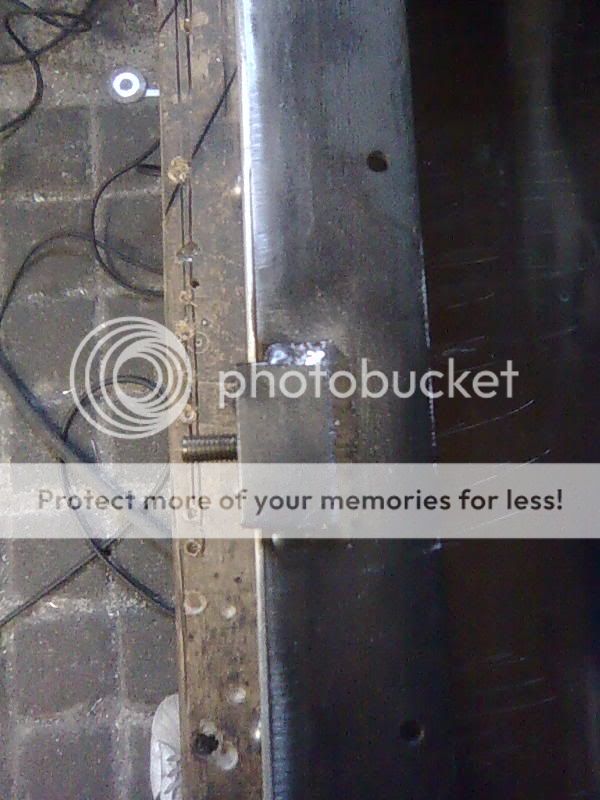

after having a sleepless night about where i was going to get the bush from to rotate the linkage on. i went to work the other day and discovered this on my work bench. it is basically what is left over after fitting a new door closer to a door at work

trimmed and welded in place

fitted a 6mm uniball end i got from ebay

i am now just waiting for a 6mm stainless threaded rod to arrive from ebay that will link to the uniball on the accellerator pedal. i can then do a little tweaking, fit the stop for the linkage then run the cable.