Hello

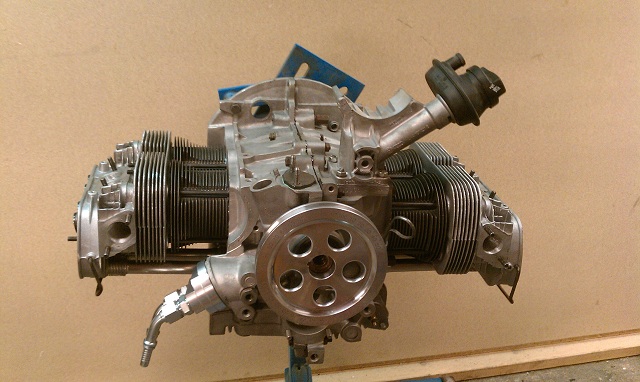

Nice to see a serious WBX engine built in a early westy, it is also used here in Denmark (mostly in type1).

Question:

I have just bought a modified CU type4 engine for my 68' westy.

It is already converted to upright cooling, trimmed to 110 hp with twin 45 dellortos and has a 228mm flywheel.

I will mate it with a 6 rib gearbox from a 77 latebay, so the flywheel should fit.

You wrote about using a starter from a TDI powered 4 cylinder car.

Did you end up doing this? (with spacer) and do you have any suggestions which starter i should chase?

(i will update my old thread, when i'm doing the swap.)

Regards

Ronnie

Copenhagen

Nice to see a serious WBX engine built in a early westy, it is also used here in Denmark (mostly in type1).

Question:

I have just bought a modified CU type4 engine for my 68' westy.

It is already converted to upright cooling, trimmed to 110 hp with twin 45 dellortos and has a 228mm flywheel.

I will mate it with a 6 rib gearbox from a 77 latebay, so the flywheel should fit.

You wrote about using a starter from a TDI powered 4 cylinder car.

Did you end up doing this? (with spacer) and do you have any suggestions which starter i should chase?

(i will update my old thread, when i'm doing the swap.)

Regards

Ronnie

Copenhagen