The pedal set up on my 71 was not opening up the throttle fully -- just half way. Comparing photos of the linkage and bell crank to parts diag I realized the bellcrank was installed inverted reducing the leverage. I thought that should be an easy 30min fix. Well, not quite...

Here's the original set up. The lower linkage rod is on the shorter arm of the bell crank and the pedal on the longer

The crank was inserted from the left side of the mount, not from the right as it should be. This made the shorter arm point down and the longer one point horizontal and be hooked to the pedal instead.

But, when I had removed the long link (link in the photo), I realized that there is not enough space on the left to pull out the bell crank as a cross member gets in the way. How did they install this??

Answer: By tearing out the mount and then welding bolts to refit it to the floor:

Once I got it out I realized refitting is going to be a challenge as the mount is not symmetrical - the thru hole on it is at an angle. So, I had to try both orientations. In one orientation (the first that I tried), it would bind. So, had to dismount it and reinstall. The previous mech had drilled and installed brass bushings to eliminate slop -- at first I thought it was good idea. But, the bushings also eliminate the little bit of flex needed to get the linkage inserted thru the holes in the cranks and pedal. So needed a lot of trial and error to figure out the combination in which the assembly would go back together. The original spring clips had been replaced by cotter pins -- but the holes had been drilled in inconvenient positions which made getting the pins in a challenge.

I finally had the pedal and bell crank mounted. just needed the lower linkage installed -- when I discovered that the lower linkage was too long. With pedal fully up and throttle fully closed the linkage was too long by about half inch. So, I decided to shorten the lower linkage by bending it.

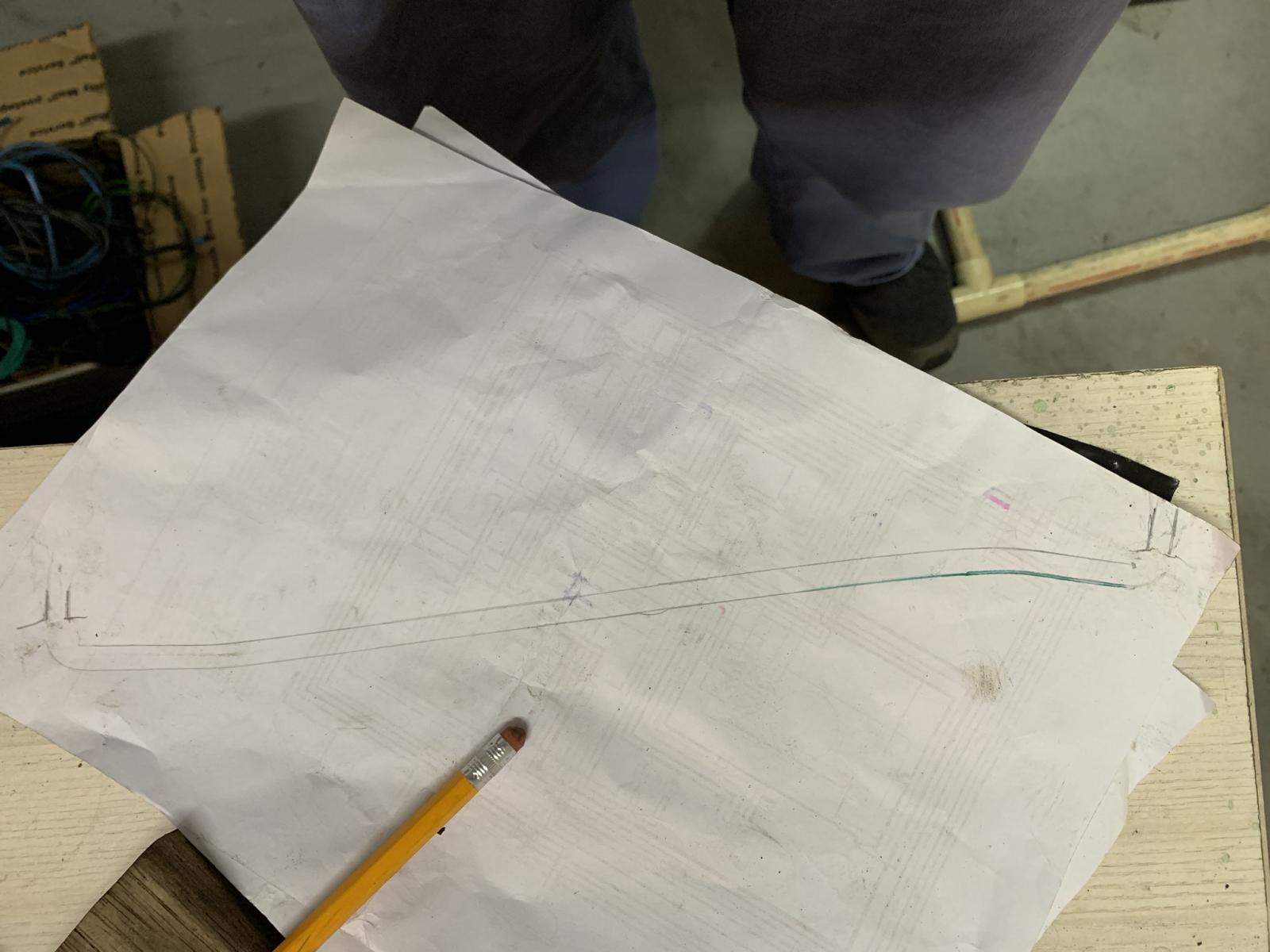

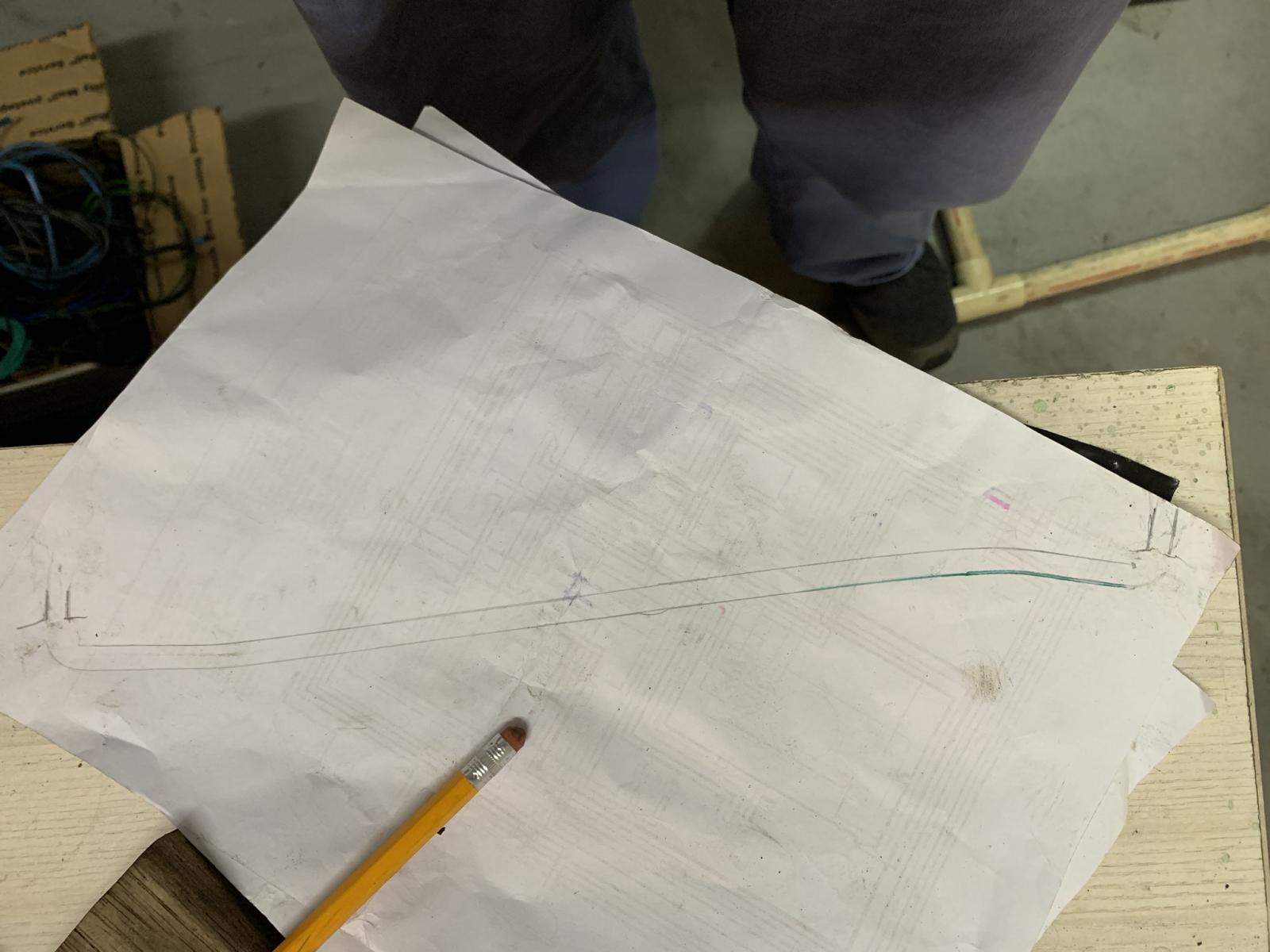

First I traced the linkage shape to have as reference.

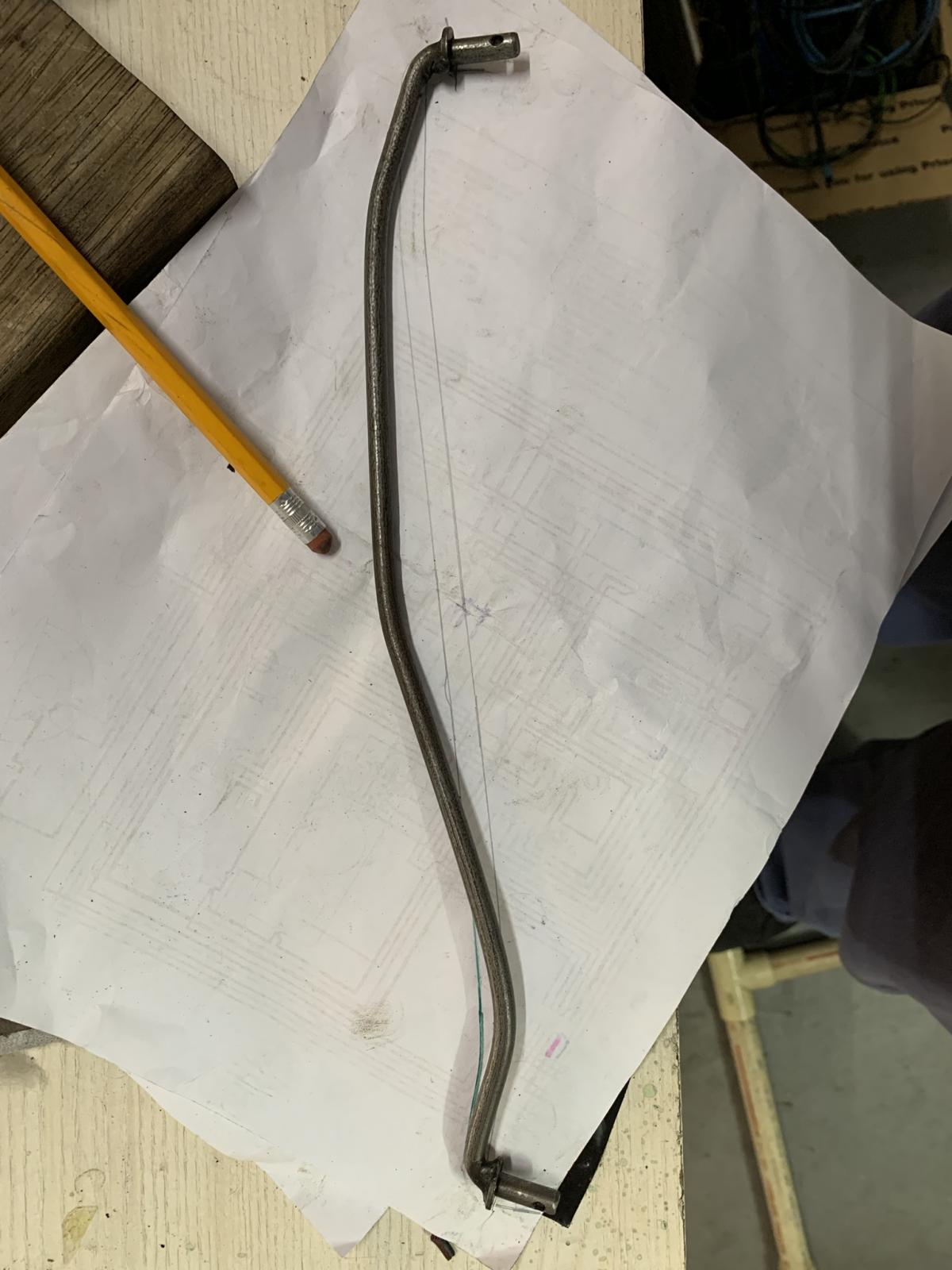

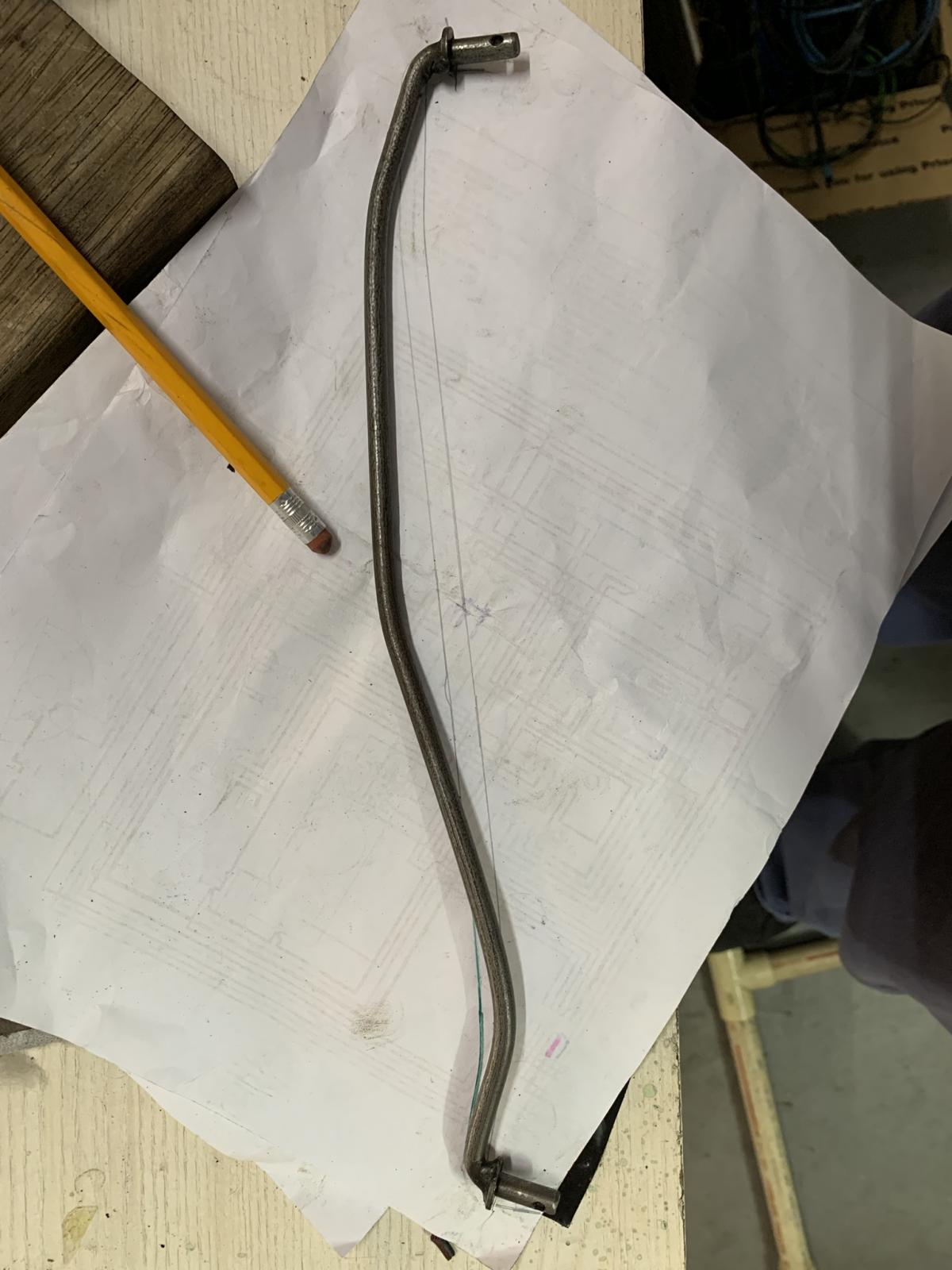

Then bent the linkage until it was shorter, but with the mounting ends maintaining a similar relative position.

After a few cycles of trying, rebending, refitting, it finally slid it.

I then confirmed that the throttle opened fully.

My 30min estimate was off by 3 hours. :roll:

I'm wondering why the lower linkage was off in length. I know there is an early linkage (till 69) and a 70-on available. VWHeritage does show 2 linkage of different lengths in a kit. What would the correct length be for a 71 RHD lower linkage? Part number 214721627A? Anyone have one handy to measure?

I plan to weld back the mount and repair the floor near it. Then replace the push rods with ball ends. I know Buty offers a kit. But, I don't need the bell crank and I think I can just buy some ball ends and create my own linkage locally vs. $100+shipping + 50% import duty for the kit from

VWHeritage or elsewhere.

Btw, I just discovered that VW Heritage sells just the pedal linkage for about $10. I think I'll buy 2, use one from pedal to bell crank and get a longer rod for the second and use that for the lower linkage. Anyone tried that?

Cheers!

Byas

Here's the original set up. The lower linkage rod is on the shorter arm of the bell crank and the pedal on the longer

The crank was inserted from the left side of the mount, not from the right as it should be. This made the shorter arm point down and the longer one point horizontal and be hooked to the pedal instead.

But, when I had removed the long link (link in the photo), I realized that there is not enough space on the left to pull out the bell crank as a cross member gets in the way. How did they install this??

Answer: By tearing out the mount and then welding bolts to refit it to the floor:

Once I got it out I realized refitting is going to be a challenge as the mount is not symmetrical - the thru hole on it is at an angle. So, I had to try both orientations. In one orientation (the first that I tried), it would bind. So, had to dismount it and reinstall. The previous mech had drilled and installed brass bushings to eliminate slop -- at first I thought it was good idea. But, the bushings also eliminate the little bit of flex needed to get the linkage inserted thru the holes in the cranks and pedal. So needed a lot of trial and error to figure out the combination in which the assembly would go back together. The original spring clips had been replaced by cotter pins -- but the holes had been drilled in inconvenient positions which made getting the pins in a challenge.

I finally had the pedal and bell crank mounted. just needed the lower linkage installed -- when I discovered that the lower linkage was too long. With pedal fully up and throttle fully closed the linkage was too long by about half inch. So, I decided to shorten the lower linkage by bending it.

First I traced the linkage shape to have as reference.

Then bent the linkage until it was shorter, but with the mounting ends maintaining a similar relative position.

After a few cycles of trying, rebending, refitting, it finally slid it.

I then confirmed that the throttle opened fully.

My 30min estimate was off by 3 hours. :roll:

I'm wondering why the lower linkage was off in length. I know there is an early linkage (till 69) and a 70-on available. VWHeritage does show 2 linkage of different lengths in a kit. What would the correct length be for a 71 RHD lower linkage? Part number 214721627A? Anyone have one handy to measure?

I plan to weld back the mount and repair the floor near it. Then replace the push rods with ball ends. I know Buty offers a kit. But, I don't need the bell crank and I think I can just buy some ball ends and create my own linkage locally vs. $100+shipping + 50% import duty for the kit from

VWHeritage or elsewhere.

Btw, I just discovered that VW Heritage sells just the pedal linkage for about $10. I think I'll buy 2, use one from pedal to bell crank and get a longer rod for the second and use that for the lower linkage. Anyone tried that?

Cheers!

Byas