When removing my J-tubes to fit my heat exchangers the threaded stud (...?) came out with the nut instead of the nut coming off alone from the front of the engine (gearbox end). Is there any reason I shouldn't reuse these like a bolt instead of a nut onto a thread?

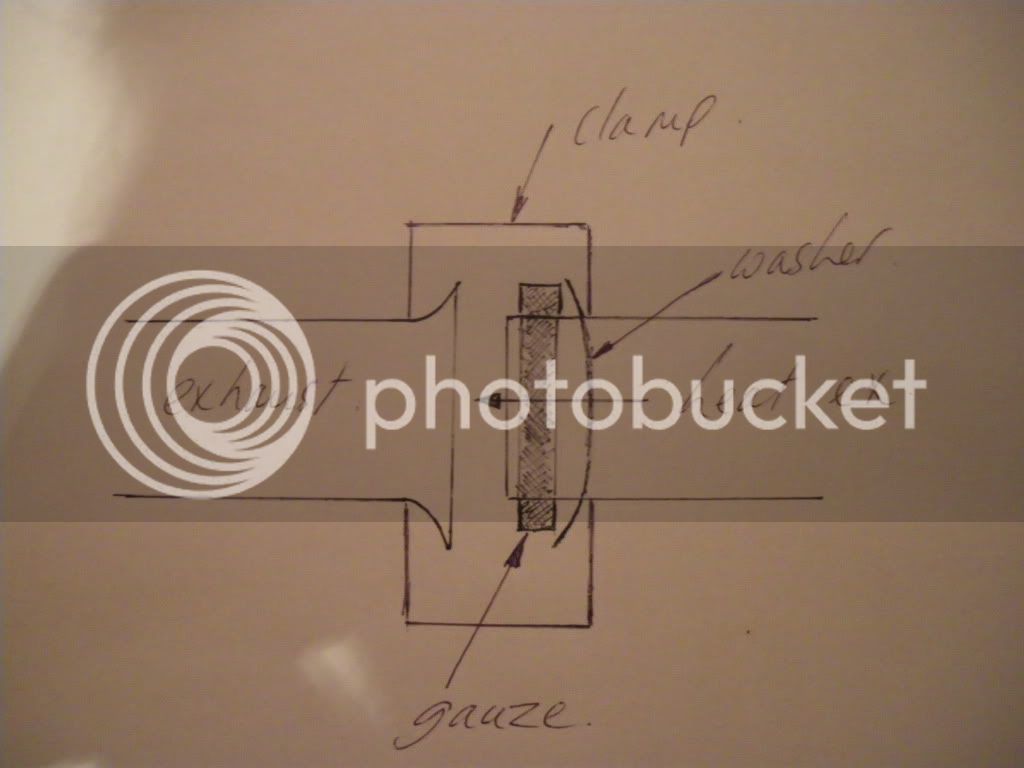

I also bought a fitting kit (gaskets & clamps etc) from JK, and the clamps (heat exchanger to exhaust) came as two large diameter washers either side of a wire gauze all inside the clamp, however the gause and washers don't fit over the exhuast so I have had to remove these to fit the clamp, will this have any negative effects if I just use firegum to seal the two together withthe clamp?

Running out of time to get the van running for the Christmas meet on Sunday :evil:

I also bought a fitting kit (gaskets & clamps etc) from JK, and the clamps (heat exchanger to exhaust) came as two large diameter washers either side of a wire gauze all inside the clamp, however the gause and washers don't fit over the exhuast so I have had to remove these to fit the clamp, will this have any negative effects if I just use firegum to seal the two together withthe clamp?

Running out of time to get the van running for the Christmas meet on Sunday :evil: