redwards

Well-known member

Hi all,

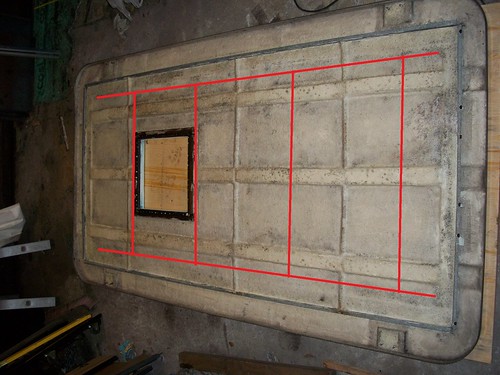

As we enter a new year, I am on a push to get the bus sorted. The weather last year literally put a dampner on things. After I stripped the interior I found the poptop was leaking, through the fibreglass. I have pull the top off and stripped everything off it, I have also picked up some 20x20mm Ali U channel.

100_2215

100_2217

The roof is all fibreglass, the thinner cross supports are cardboard rods with a thin wire through the centre. The 3 thicker ribs are filled with expanding foam. Around the edge is what appears to z profile metal which has been fibreglassed over to bond it in place.

So, has anyone repaired this type of roof before (I've seen 2/3 online)? My plan is to run the Ali down the full length (outside the ribs), then 3 strips to replace the cardboard tube.

Any help will be greatly appreciated. Thanks, Rich.

As we enter a new year, I am on a push to get the bus sorted. The weather last year literally put a dampner on things. After I stripped the interior I found the poptop was leaking, through the fibreglass. I have pull the top off and stripped everything off it, I have also picked up some 20x20mm Ali U channel.

100_2215

100_2217

The roof is all fibreglass, the thinner cross supports are cardboard rods with a thin wire through the centre. The 3 thicker ribs are filled with expanding foam. Around the edge is what appears to z profile metal which has been fibreglassed over to bond it in place.

So, has anyone repaired this type of roof before (I've seen 2/3 online)? My plan is to run the Ali down the full length (outside the ribs), then 3 strips to replace the cardboard tube.

Any help will be greatly appreciated. Thanks, Rich.