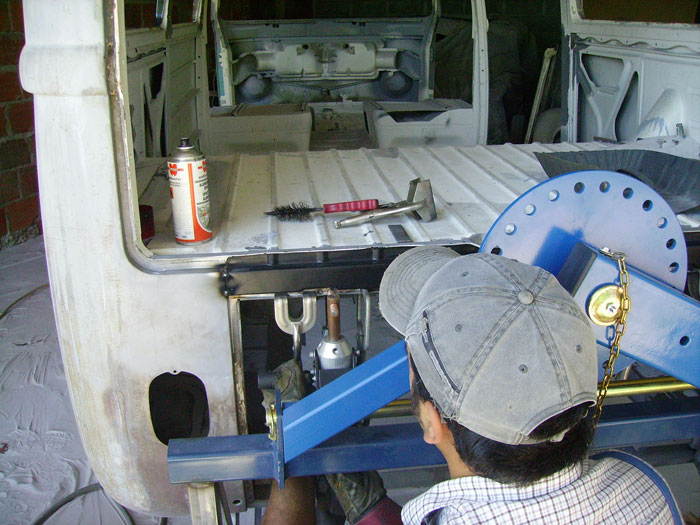

Glad you are still working on the bus

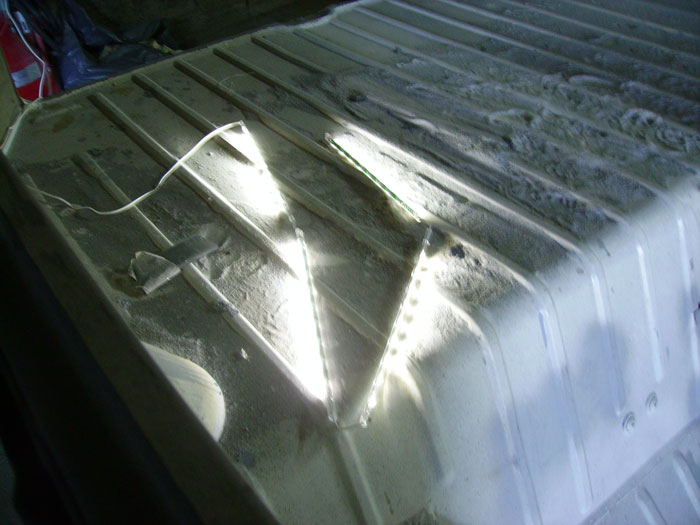

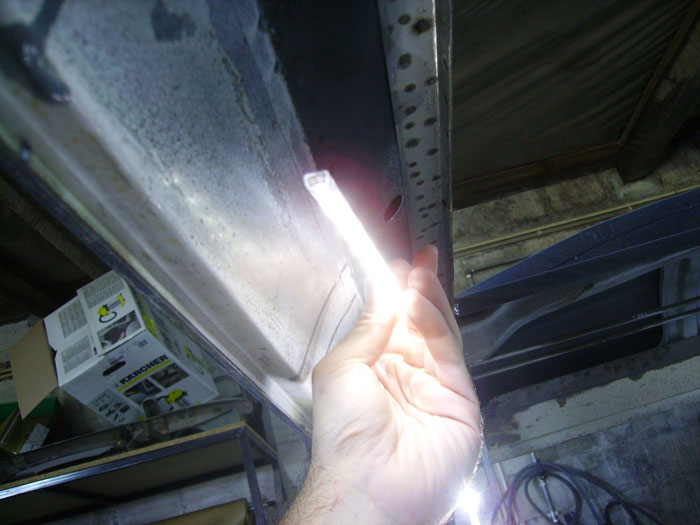

Looks like you have done a good job with the roof - used plenty of POR 15 (not cheap) and like you say, hope it does what it says on the tin

Looking forward to the updates :mrgreen:

Looks like you have done a good job with the roof - used plenty of POR 15 (not cheap) and like you say, hope it does what it says on the tin

Looking forward to the updates :mrgreen: