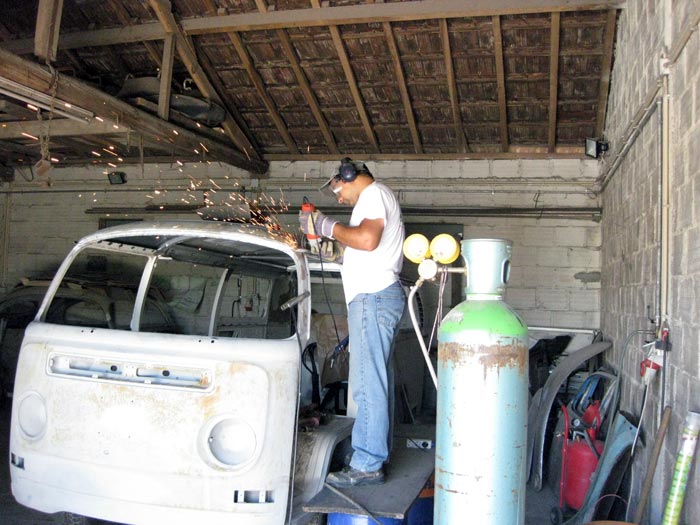

after welding all the parts in place, hugo started grinding all the welding excesses on the roof:

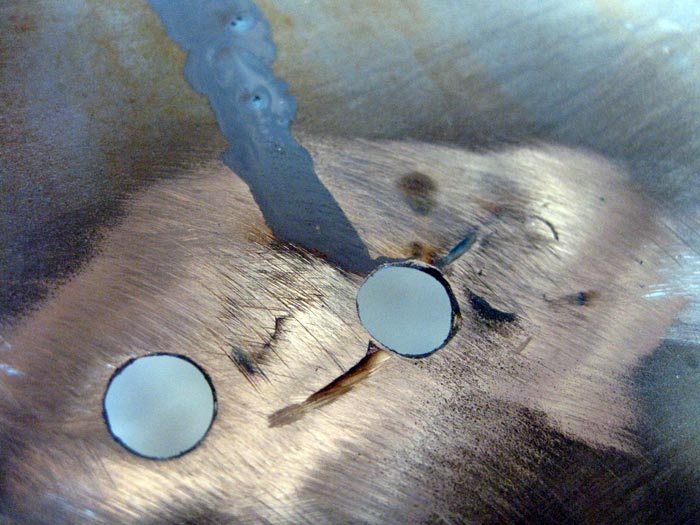

and here was when Hugo really started changing his mind about POR-15 products. The paint was really sticked to the roof.

While the metal gets grinded the paint remains in place :shock:

I just hope it really works.

and a general view of the task in progress:

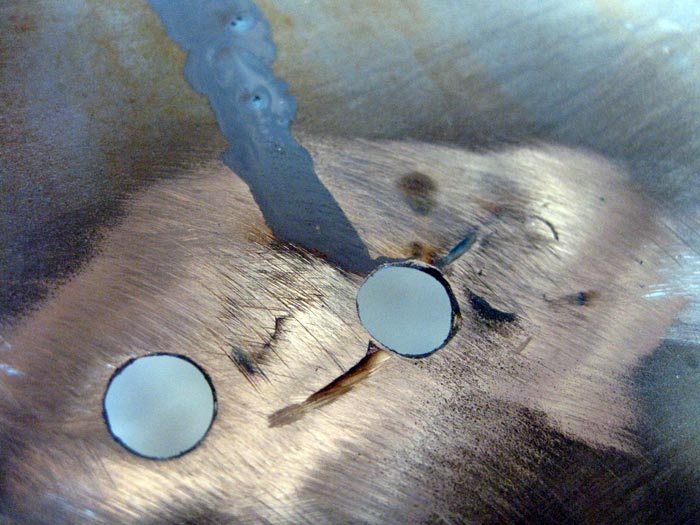

and after everything in place and before we started welding the roof, we filled all the empty spaces of the bus with 3M cavity wax. A lot more liquid than the one from Dinitrol:

.... and a couple of minutes later, we realized that the wax was leaving the bus from all the small holes:

If there hasn't been a huge rust treatment on the bus originaly, now I hope it will resist, at least, a few decades :mrgreen:

and here was when Hugo really started changing his mind about POR-15 products. The paint was really sticked to the roof.

While the metal gets grinded the paint remains in place :shock:

I just hope it really works.

and a general view of the task in progress:

and after everything in place and before we started welding the roof, we filled all the empty spaces of the bus with 3M cavity wax. A lot more liquid than the one from Dinitrol:

.... and a couple of minutes later, we realized that the wax was leaving the bus from all the small holes:

If there hasn't been a huge rust treatment on the bus originaly, now I hope it will resist, at least, a few decades :mrgreen: