So today's progress...

- broke the fuel pump pedestal out (they must swell up the hell of a lot as it took some bashing out)

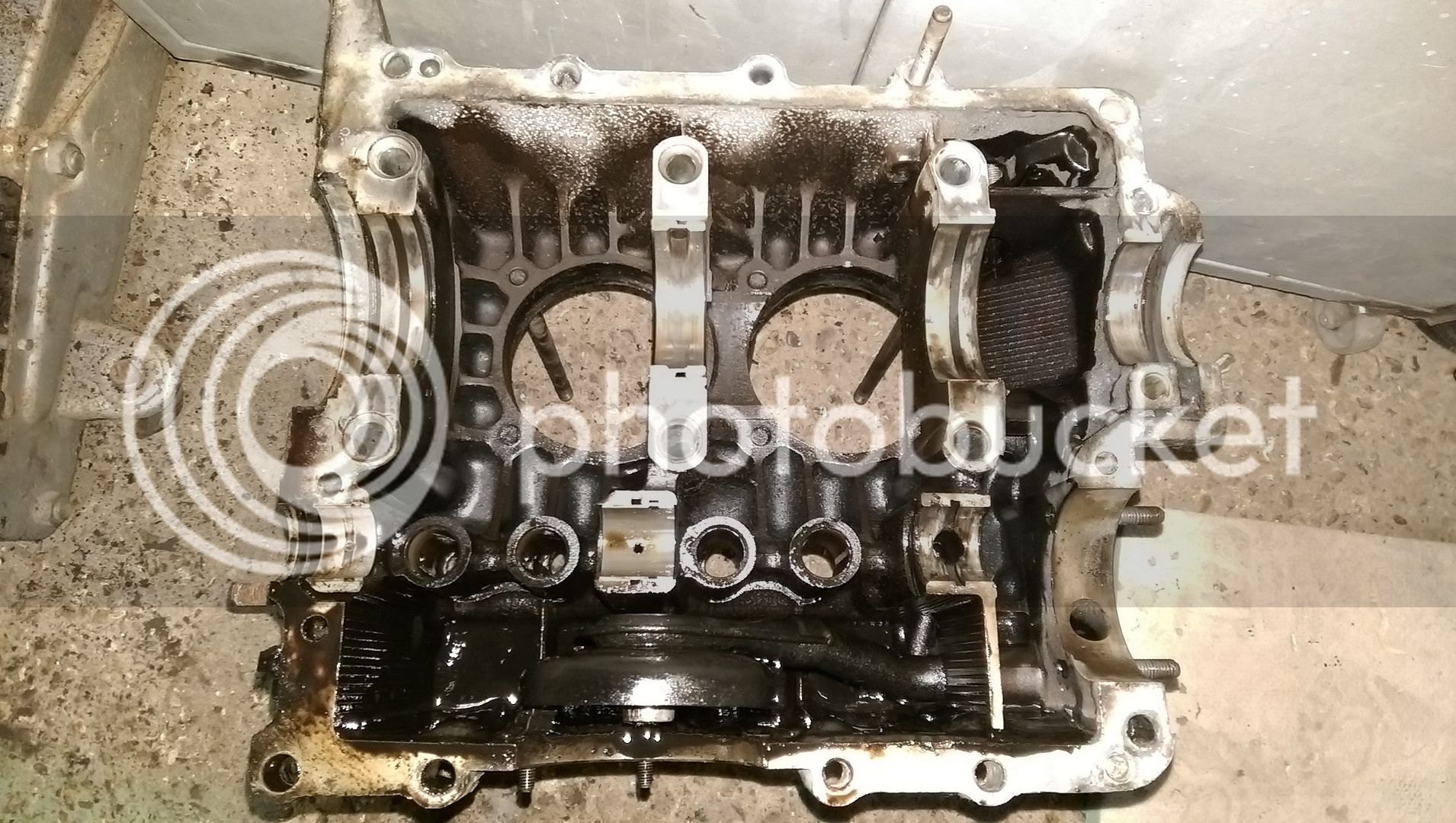

- removed the oil pressure relief valve plungers using a M12 tap and dragging them out (I didn't have any luck with the screwdriver). Both valves looked the same, even though the pictures I've seen of them one appears to have a groove in it.

- measured the side play in the con rods. Appears to be around 0.25mm, so within specs.

- took off the bearings from the crank as far as the dizzy and timing gear, but those are stuck.

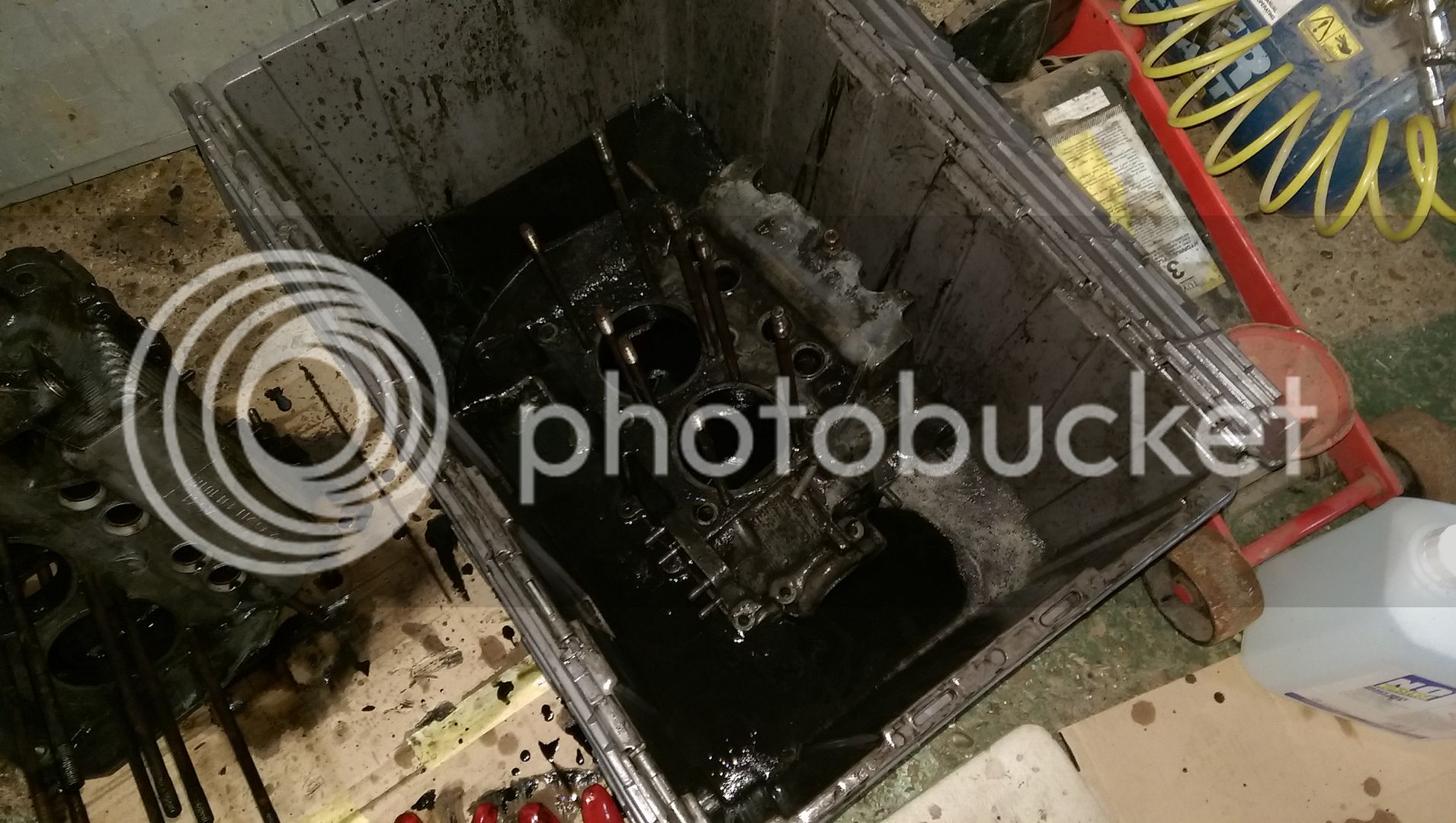

I think I'm going to have to buy the puller for the gear. I heated it up with a blow torch and the distirbutor gear moved a bit but I couldn't manage to get it off. The rest of the crank was heating up and I assume that expanded too much. Tried popping it in the freezer for 20 mins while I had a cup of tea and then tried to just heat the gear, but no luck getting it off. It doesn't appear to be possible to get a grip of it with a normal 3 legged puller, so I think I'm just going to have to get the right one.

The crank itself looked ok with no major scoring on the surfaces and I can hardly feel anything with my fingernails, so I don't think that will need any work.

With regards to new bearings, if the crank has no work done to it and the case doesn't have to have any, do I just get a normal set of bearings and put those in?