Ebeneezer

Active member

Quick background. Used to have a Beetle when I was in early twenties and fancied a Bay. Looked at a couple then saw one that looked ok in the pictures on Ebay. Didn't get time to go and look at it but in the early hours of one Sunday morning having drunk far too much red wine and cheered on by my brother-in-law found myself bidding a grand and winning it.

The description read :

All welding has been done (he forgot to say badly done by Blind Pugh!)

Lots of new panels (in most cases badly welded over the old ones!)

Complete engine (carefully stored in a least 12 separate boxes)

Sound chassis (at least what he could see of it, the bits under the belly pans are not so good!)

Easy project (if you have the McLaren workshops and team of mechanics at your disposal)

Unfortunately I have no pictures of vehicle in this sorry state as the camera died out of mechanical sympathy.

Took poor vehicle to various restorers who would "start on it as soon as this one's done, mate!"

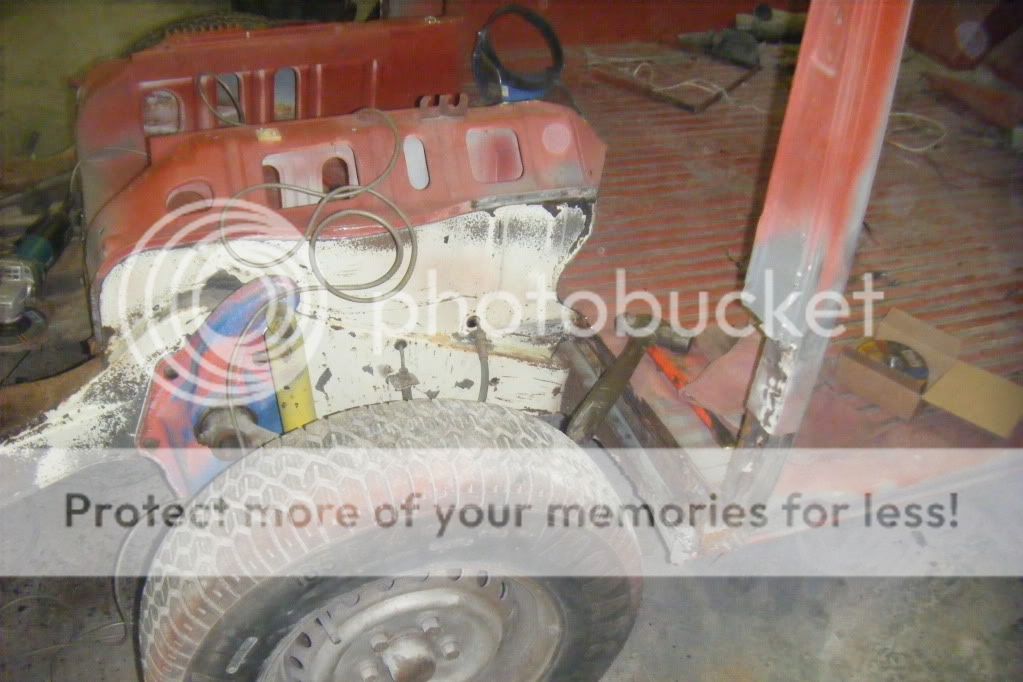

Two and a half years later and it's been sand-blasted, coated in primer and had a new front panel tacked into position.

Thats when I agreed with the latest restorer that I will drive 90 minutes every sunday morning to spend all day working on the van in his workshop and under his guidance during which he will teach me to weld and do panelwork.

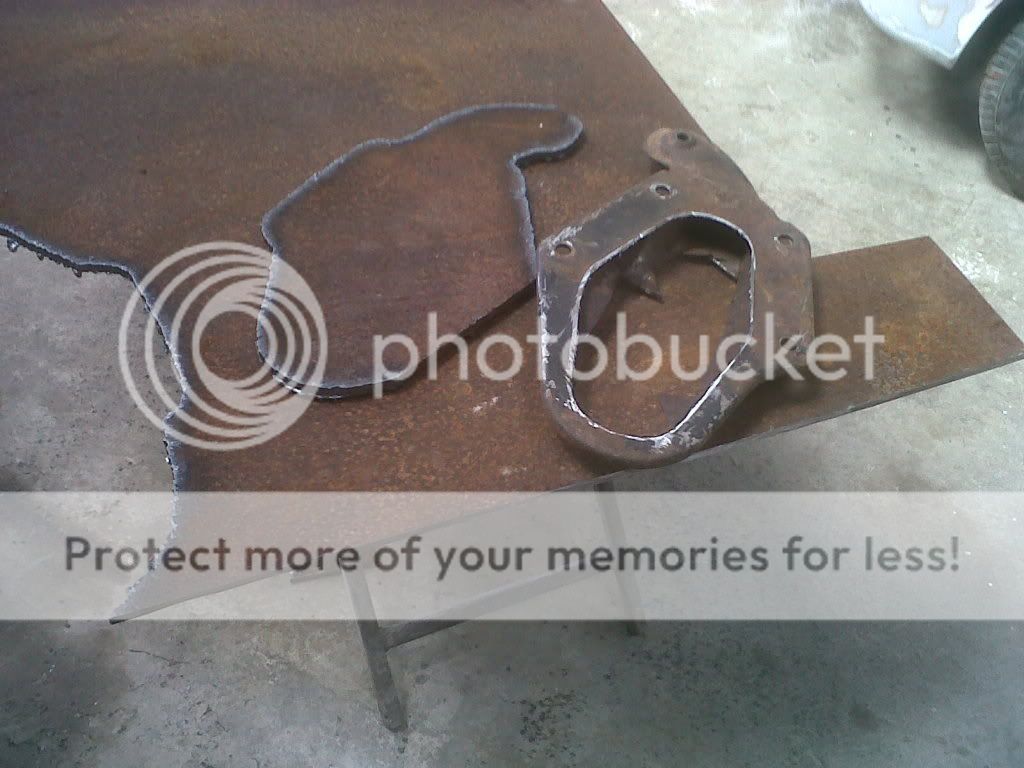

Here's where things started on 13 the 2009 :-

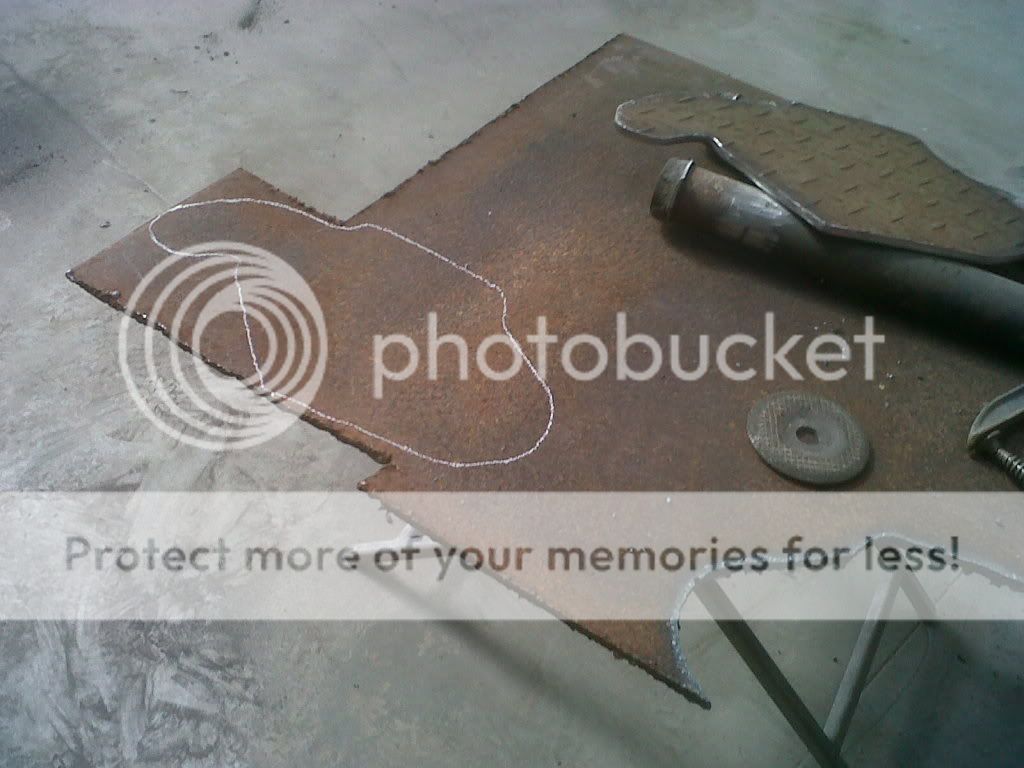

Oh, cab floor was rotten so my first job was to chop that out with a 9" cutter - bloody dangerous things.

Oh, and the wheel arches that had been replaced were wrong and had to come out too!

So while I had the grinder going I decided to take out the seat backs too.

The description read :

All welding has been done (he forgot to say badly done by Blind Pugh!)

Lots of new panels (in most cases badly welded over the old ones!)

Complete engine (carefully stored in a least 12 separate boxes)

Sound chassis (at least what he could see of it, the bits under the belly pans are not so good!)

Easy project (if you have the McLaren workshops and team of mechanics at your disposal)

Unfortunately I have no pictures of vehicle in this sorry state as the camera died out of mechanical sympathy.

Took poor vehicle to various restorers who would "start on it as soon as this one's done, mate!"

Two and a half years later and it's been sand-blasted, coated in primer and had a new front panel tacked into position.

Thats when I agreed with the latest restorer that I will drive 90 minutes every sunday morning to spend all day working on the van in his workshop and under his guidance during which he will teach me to weld and do panelwork.

Here's where things started on 13 the 2009 :-

Oh, cab floor was rotten so my first job was to chop that out with a 9" cutter - bloody dangerous things.

Oh, and the wheel arches that had been replaced were wrong and had to come out too!

So while I had the grinder going I decided to take out the seat backs too.