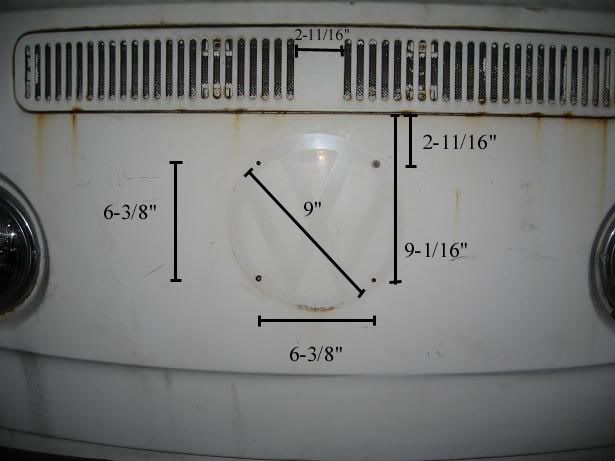

I finally got our NOS nose badge fitted, with measurement help from

@mike202

I drew a template on CAD, covered it in clear tape to make it more robust, then i folded the top edge to rest into the air box lower edge, masking taped it on centreline.

It must have been close as my pilot drill hit hard spots of the welding which filled the holes up a few years back. Snapped loads of 3-4 mm drills & got pushed off centre because of the hard weld spots so used a dremel/diamond burr to gradually work everything back on target as i increased to the size required for the plastic plugs. Sweating in case i slipped & wrecked the paint. Template helped a lot here, left taped in situ. Drills grabbed those hard welds a few times & pulled the chuck hard onto the panel which would have ruined the paint had it not been protected by the template, which was pure luck.

I have the template as a PDF if it can help anyone else.

I like the end result in the correct position & how the badge stands off the bodywork on the head of the plastic plugs, compared to the repro badge which was stuck flush onto the paint.

The drill hole i settled for was ¼ inch rather than the 6mm suggested elsewhere online (& by WW for their repro front panels.) 6mm was just too tight to push in the plugs without taking paint off. Badge was still a very firm push fit into the plastic plugs, which i put into the holes first, so the badge pin then expands the plugs to lock it in. I think it could still be removed if needed using a plastic tool with care for when our front panel needs a repair.