Well she failed yesterday on 6 counts a couple of bits of welding

This is just by the offside rear jacking point I've also found a mahoosive gaping hole behind the offside wheel arch that had been covered up with a large plastic mudflap thing

Now some of the front shock mounts apparently the bottoms are hitting the beam causing them to have bent?

It's the same on the other side too any ideas how to sort it the mot guy said raise it back up and wack them straight but won't this weaken the mounts

Thanks for any advice dudes

Mark

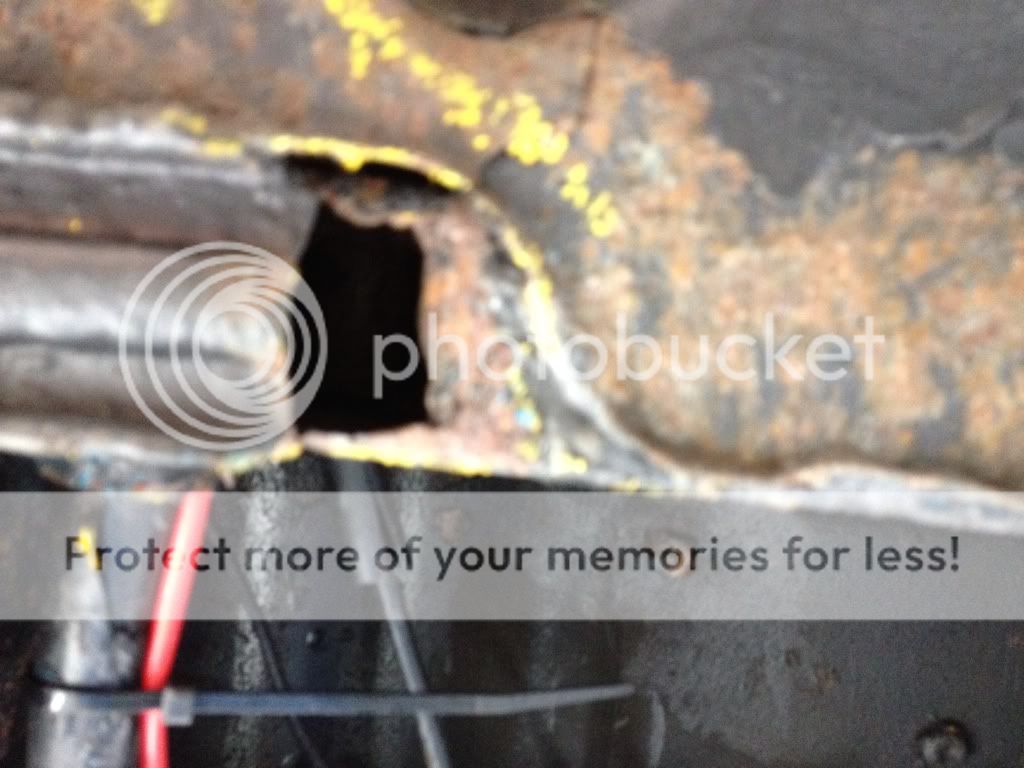

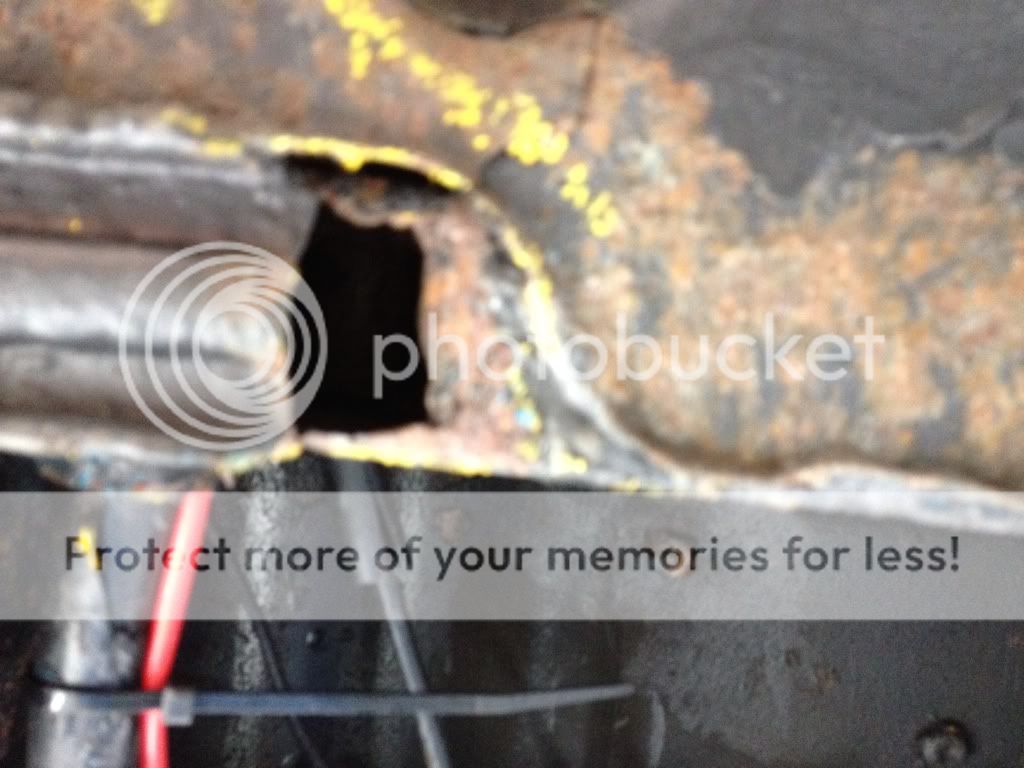

Ps this is the mahoosive hole

This is just by the offside rear jacking point I've also found a mahoosive gaping hole behind the offside wheel arch that had been covered up with a large plastic mudflap thing

Now some of the front shock mounts apparently the bottoms are hitting the beam causing them to have bent?

It's the same on the other side too any ideas how to sort it the mot guy said raise it back up and wack them straight but won't this weaken the mounts

Thanks for any advice dudes

Mark

Ps this is the mahoosive hole