Ldv126

Member

- Joined

- Sep 26, 2017

- Messages

- 13

- Reaction score

- 5

- Location

- Nottingham

- Year of Your Van(s)

- 1968

- Van Type

- T2 Dormobile

Hi All

First time poster.... !

!

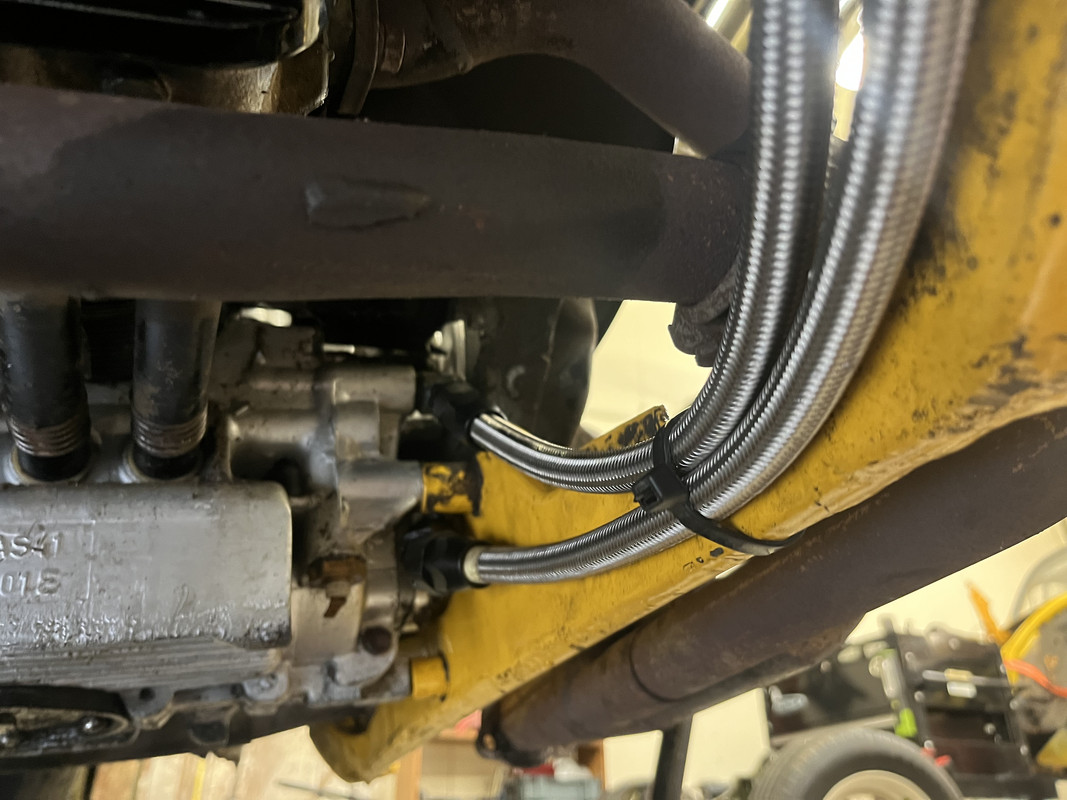

We have a '68 Dormobile with a 1914 engine that's been great for the last few years - had it since 2003, full restoration; love it! - it has a full flow oil system (proper filter / external cooler underneath / hydraulic hoses / jubilee clips).

We've had the odd oil hose problem where it popped off the engine which we can usually fix (replace filter sometimes / put it back together / top up oil etc). The last time it happened was on the motorway - had to call breakdown man, who had a quick glance and said "Wrong hoses. They're hydraulic hoses and the jubilee clips won't compress them enough. You need proper hydraulic hoses".

That all makes sense, but just finding info on getting hydraulic hoses made and fitted is proving 'challenging'!

Can anyone help with a couple of things?

1) What's the right thing to do, to stop oil hoses coming off?

2) Is there some useful information out there that I can have a read of to understand what I need to do if I want to go hydraulic?!?

I'm sure I'll need to provide more info - just let me know what!

Cheers in advance...

First time poster....

We have a '68 Dormobile with a 1914 engine that's been great for the last few years - had it since 2003, full restoration; love it! - it has a full flow oil system (proper filter / external cooler underneath / hydraulic hoses / jubilee clips).

We've had the odd oil hose problem where it popped off the engine which we can usually fix (replace filter sometimes / put it back together / top up oil etc). The last time it happened was on the motorway - had to call breakdown man, who had a quick glance and said "Wrong hoses. They're hydraulic hoses and the jubilee clips won't compress them enough. You need proper hydraulic hoses".

That all makes sense, but just finding info on getting hydraulic hoses made and fitted is proving 'challenging'!

Can anyone help with a couple of things?

1) What's the right thing to do, to stop oil hoses coming off?

2) Is there some useful information out there that I can have a read of to understand what I need to do if I want to go hydraulic?!?

I'm sure I'll need to provide more info - just let me know what!

Cheers in advance...