naskeet

Well-known member

Hahahah got a gauge fettish maybe? Hahah and Stella would be a reference to an Aleof sorts maybe? I get you don’t like alcohol but no likes a lead bottom or drunks I get it! But a little hummer can go a fair way to smoothing things I hope you all have a good day.

Anyway what I really want to know is when fitting a hot-rodded Type 4 engine into our busses, other than just fitting an oil cooler what mods can we do to the tinware to increase cooling due to you know a hotted up Type 4 engine?

My preference is for tea with milk, but no sugar. Alternatively, I am quite partial to various fruit juices, such as orange, grapefruit, lemon, lime, pineapple, mango, grape or guava.

People don't need to be "drunk" in order to be a greater danger when driving. Just a half-pint of beer or cider or similar quantity of alcohol from other beverages, has a measurable detrimental effect on one's judgement & reaction-times. To be on the safe side, I work on the basis that one should allow 48 hours before resuming driving, if one has been consuming any alcohol.

Make sure ALL of the casting-flash on the cylinder-head fins and inside of the aluminium-alloy fan housing, plus the fan-blades of fan & fan-hub. Use the type of fan which is used on The VW 411 & 412, which has three recessed socket-head fixing-screws instead of bolts, and a plastic conical centre. Add internal & external fins to the cylinder-head rocker covers.

Ensure that the thermostat mechanism & air-flow control-flaps function correctly without binding. Ensure that there is no oil, dirt or debris inhibiting heat transfer or restricting air-flow through the oil-cooler matrix or oil-flow though the oil-cooler's oil galleries.

One might wish to blue-print the oil-pump and mating oil galleries, plus notching the connecting-rods as recommended in one of the official Volkswagen factory bulletins, to provide spray oil-cooling for the underside of the pistons. One might also consider black-anodising the cylinder heads and crankcase to possibly increase radiant heat transfer slightly.

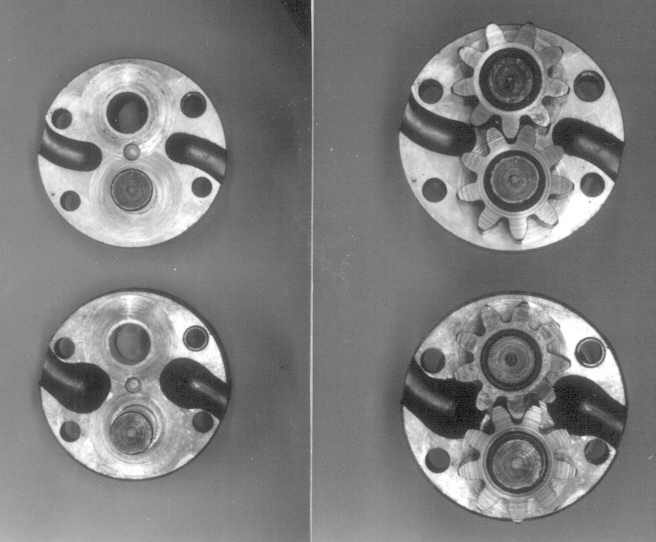

VW Type 4 oil pump – factory stock & modified

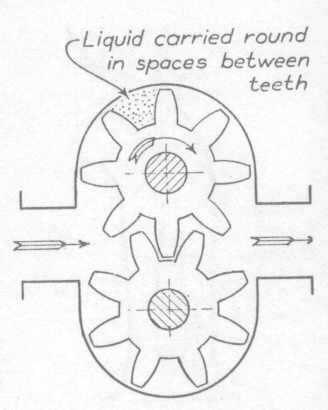

The VW flat-4 engines, are equipped with a positive-displacement, rotary, gear, oil pump; sometimes referred to as a positive-rotary gear pump.

In Bill Fisher's book re hot-rodding VW air-cooled engines, there is a reference to one after-market oil pump suffering from cavitation problems.

In an old book of mine, Herbert Addison, "The Pump Users' Handbook", Sir Isaac Pitman & Sons Ltd., 1958, Chapter 8 – Cavitation: Its Causes And Prevention, Pages 70~76, there are some relevant paragraphs, which address this issue:

« In positive-rotary pumps, cavitation sometimes manifests itself in a high-frequency vibration or rattling noise. Only experience with a particular pump and a particular liquid will show what are safe operating limits; and it is the manufacturer who should be able to give advice on this point. »

« In such machines and indeed in all positive-displacement pumps, conditions on the delivery side of the system, are quite without influence on cavitation on the suction side. It is only the suction head that matters, and not the delivery head. »

Last edited: