K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,347

- Reaction score

- 1,299

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

Now I’ve heard of them but not that particular product. It does sound like it should be one of the better performers. Not even sure how I’ve heard of them? If it cures as a primer then even better I guess. How did you get to hear of it then ?

I stumbled across it last winter when I was doing some work on my beetle. Only used it on a couple of areas but was so impressed im going all out with it on the busNow I’ve heard of them but not that particular product. It does sound like it should be one of the better performers. Not even sure how I’ve heard of them? If it cures as a primer then even better I guess. How did you get to hear of it then ?

Ozziedog,,,,,,,,,,we always like recommends

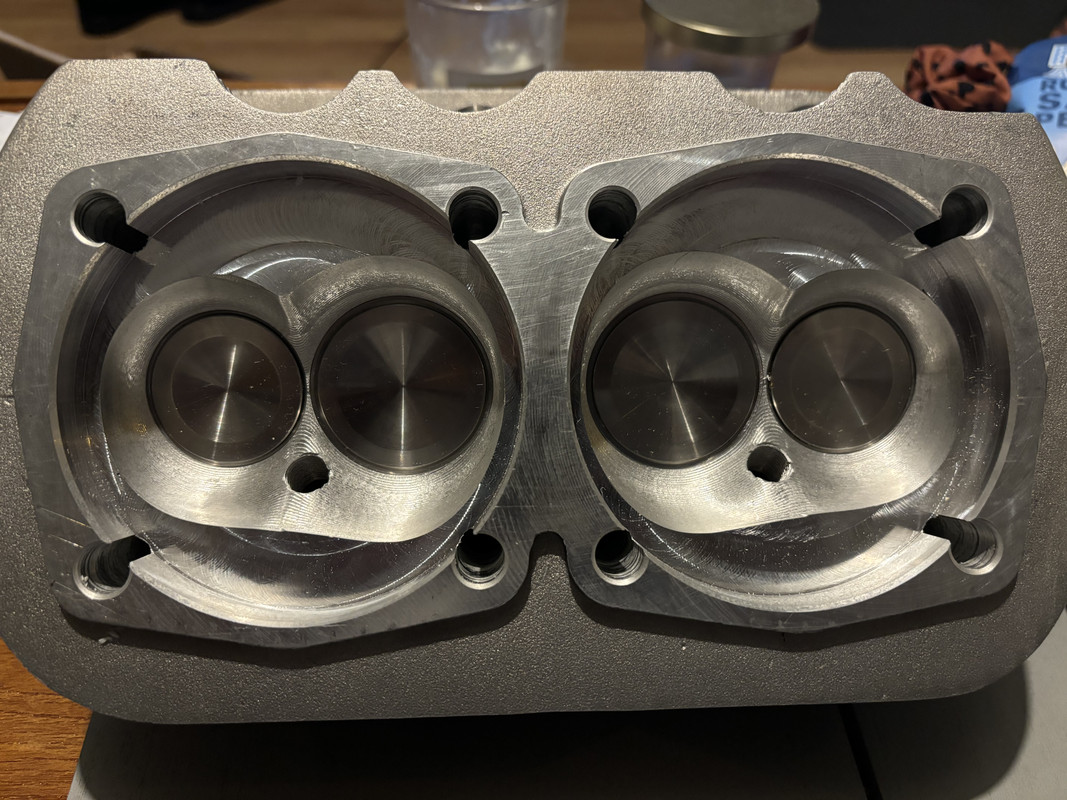

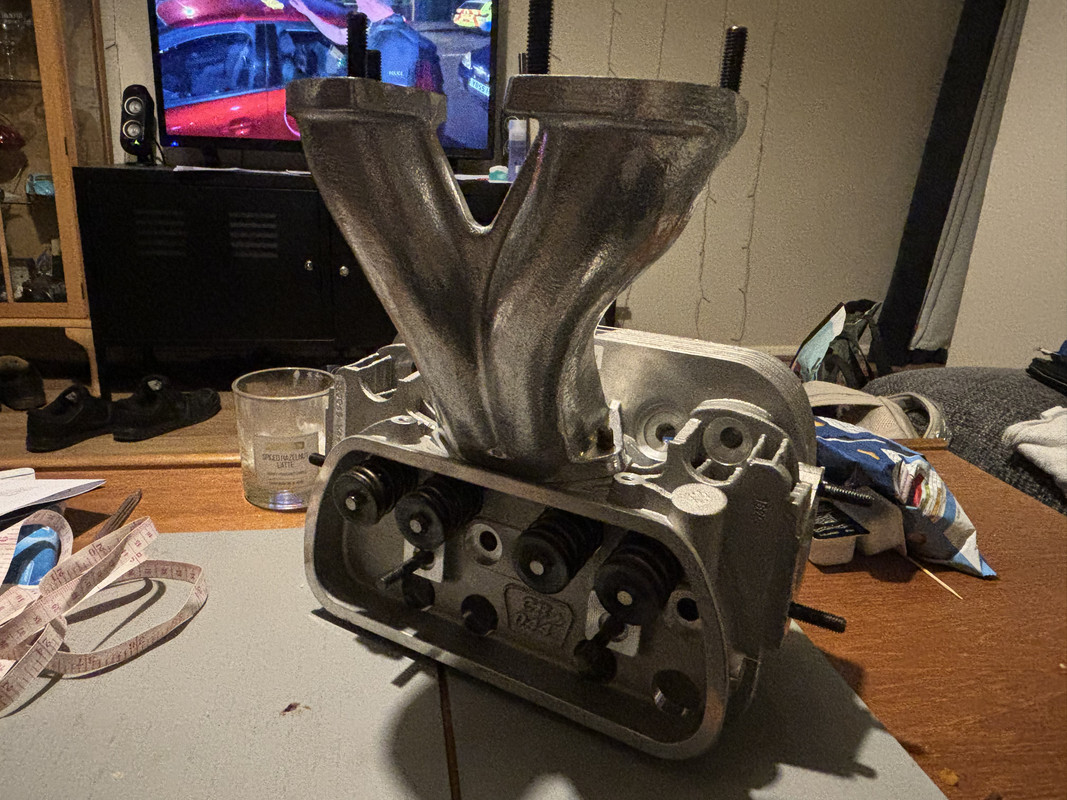

The Holley pump feeds the carbs via a matched Holley regulator set at 4psi, the other 1 is a Bosch high pressure fuel injection pump regulated down to 35psi which delivers the supplementary fuel for the nitrous system.So you have two fuel pumps, how are they configurated? And those heads look great, the valves are huge

As you know I’ve just done this, have you used spacers?

unpicked the rusty section of inner sill

Outer sill & bottom of the B are solidthat will all get a good clean and dose of anti corrosion coating before it weld the new metal in.

Something I’ve been meaning to do for literally years! Machine the snout of the drums down and fit shorter 71> stub axles so I can get the rear centre caps on.