I have neglected this thread a bit so lets see if i can detail what i have been up to.

When i fitted the engine following on from having the tin powder coated i couldn't get my hands on a front tin at a reasonable price so i had a think and then decided i would use a late bay foam engine seal, after all i guess VW changed to it for a reason. The seal is in the shape of a H so i used double sided tape to secure to the front tin slipping the edge of the front tin into the seal. I then ensured that the foam sat under the rubber early bay seal. It worked a treat and made a better seal that the original front tin that had previously.

some months later.......

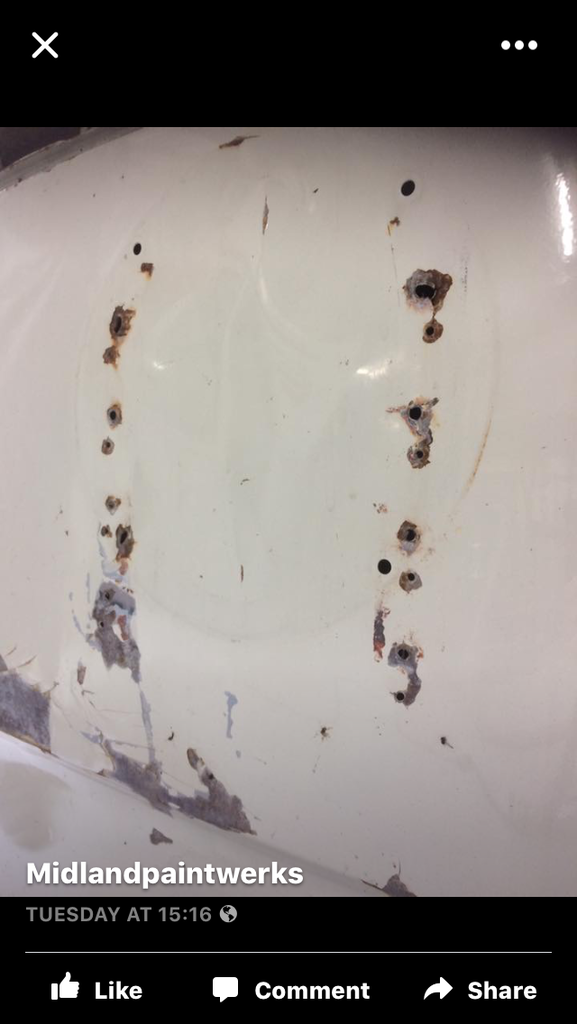

I had a slight problem with the lighting circuit in that someone in the states had put the incorrect fuse in unfortunately for me i didn't notice and further more it was of a much high rating so when the number plate light circuit decided to fail and short out the fuse didn't blow and it burnt out almost all of the loom :-( .

I decided it was best to replace the entire loom and order a bespoke loom, i had a few issues with it but these were mostly resolved by the supplier and the items that weren't i was able to sort with the help of my dad. I also sourced a mint 1970 fuse board from VWED on this forum and some german quality relays from Ron.

the first job was to remove the old loom, which i have gone through now and saved all the decent wore from should i need some correct colour trace wire at a later date, i then removed the dash and gave it a thorough clean as it was pretty grotty.

I seem to have stopped taking photos after this point, i can only assume that this where i ran into to problems and to be honest it was such a head ache at times that taking photos was certainly not at the forefront of my mind, any way the end result was a new main loom with extra wires for my air gauges, tacho and oil temp at a later date. i also replaced all of the dash loom, brake master cylinder loom, front and rear lights.

When we got it all fitted we found that the brake warning light had hoped the diode, so i sourced a replacement from maplins and fitted it, a satisfying job.

I now just need to fit the year correct NOS master cylinder i have.

Decided to go back to rubber mats in the cab, what a difference ! far less noise in the cab.

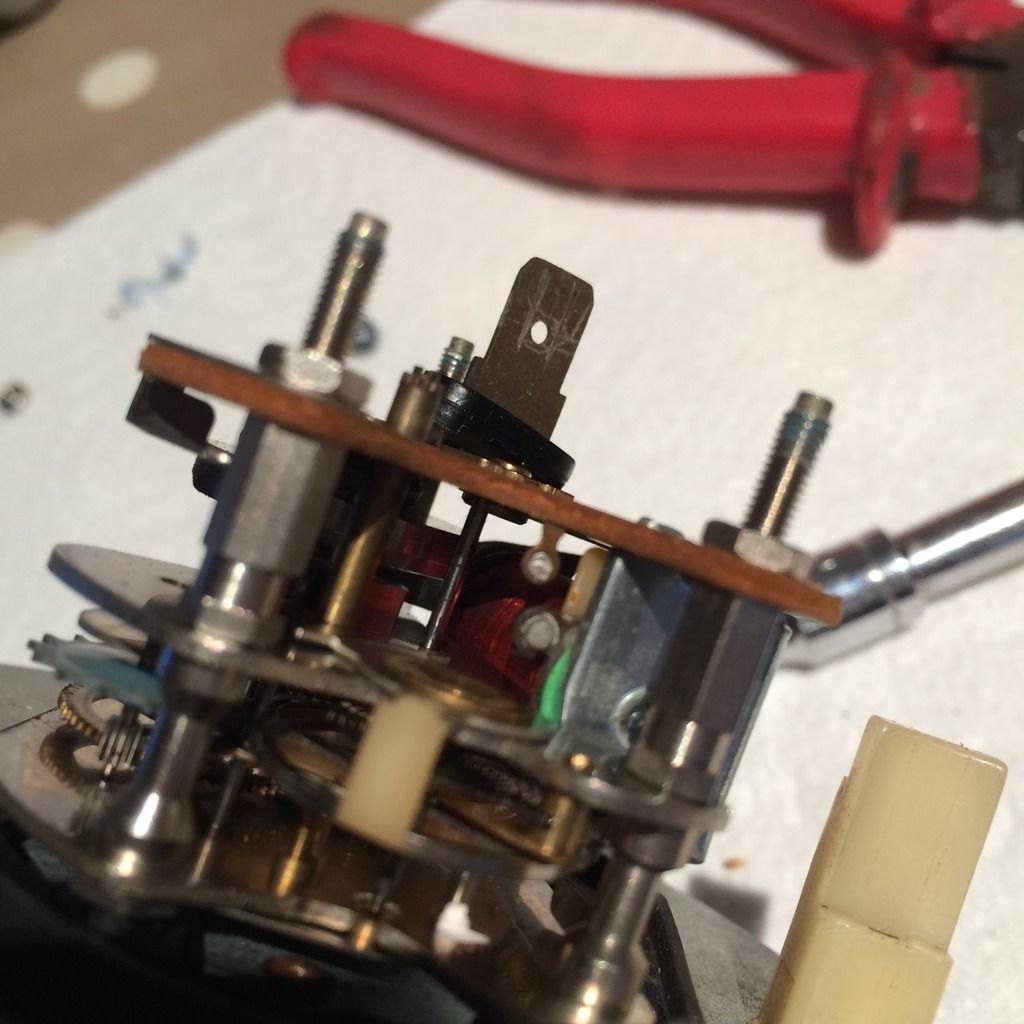

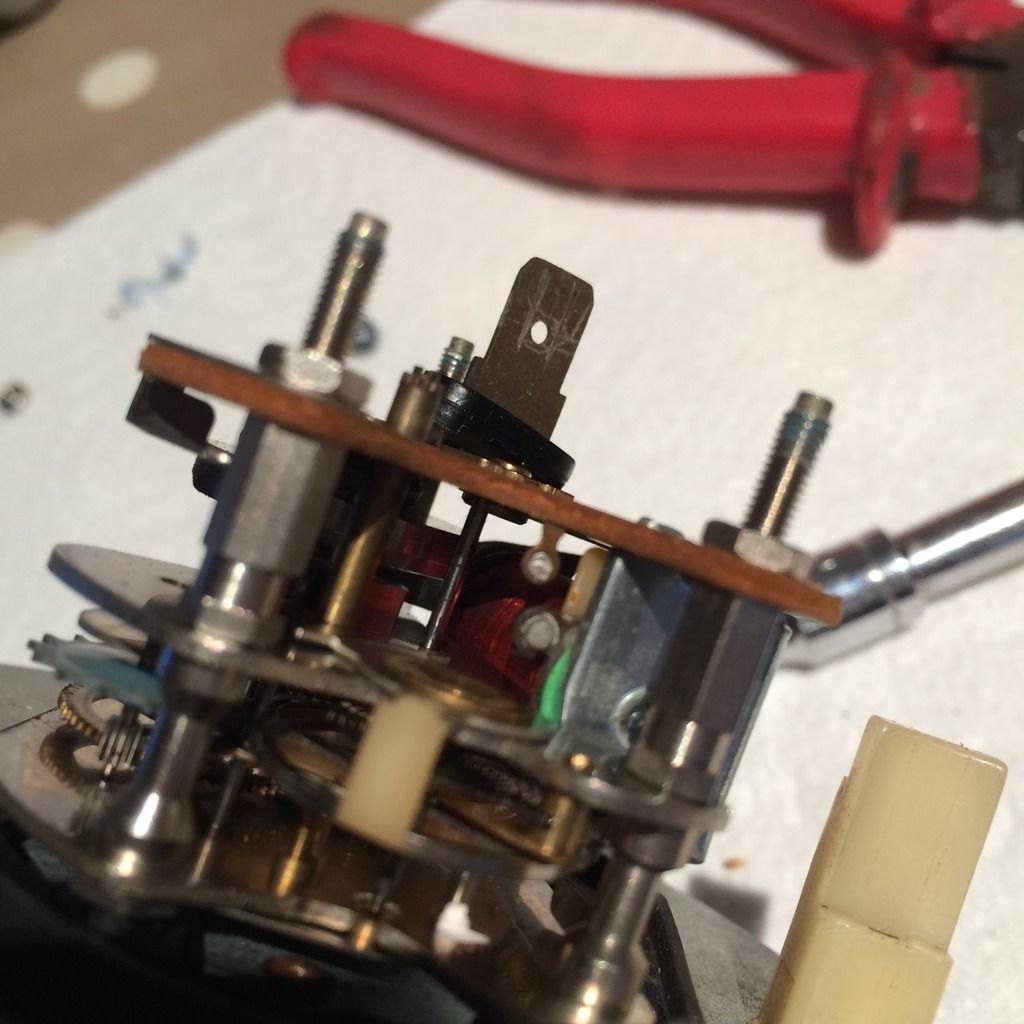

My dad got the deluxe clock working, which was a bonus, in the image you can see the two contacts that have separated, they in effect are a fuse that is made from solder that melts at different temp caused by current passing through them, or at least i think that how i remember my dad explaining it to me.

Then we shot down to cornwall to visit the family.

On my return from cornwall i decided to change the rear hubs, stub axles and bearings for some apparently better units that i had purchased about a year ago, there was no argument the stubbs were better as they were NOS but the hubs i don't thing are a great improvement, however they are serviceable and now they have the correct *** bearings in them i hope they will be good for some time.

Whilst doing this job i decided to treat the rear suspension to an inspection and paint allowing a dew little mods that i picked up of other forum members.

I found as part of the inspection that smaller portion of my adjustable spring plates (the splined part) had been fouling on the spacer between the torsion housing and the end cap, due to this i clearance it and gave it a lick of paint.