So I got my new bit of tin to put under the pully, need to remove the pully, Haynes says put something through one of the holes to stop it moving.... Except I don't have any holes, just degree markings. Any suggestions?

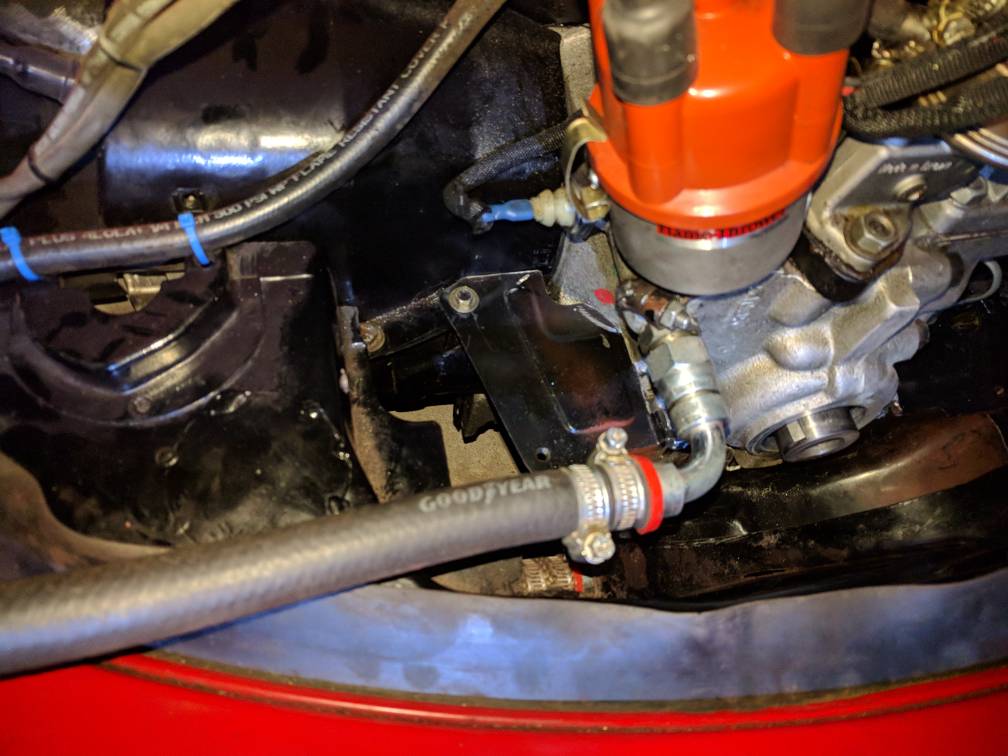

Also that lower oil pipe that goes to the external filter looks like it may be in the way?

Also that lower oil pipe that goes to the external filter looks like it may be in the way?