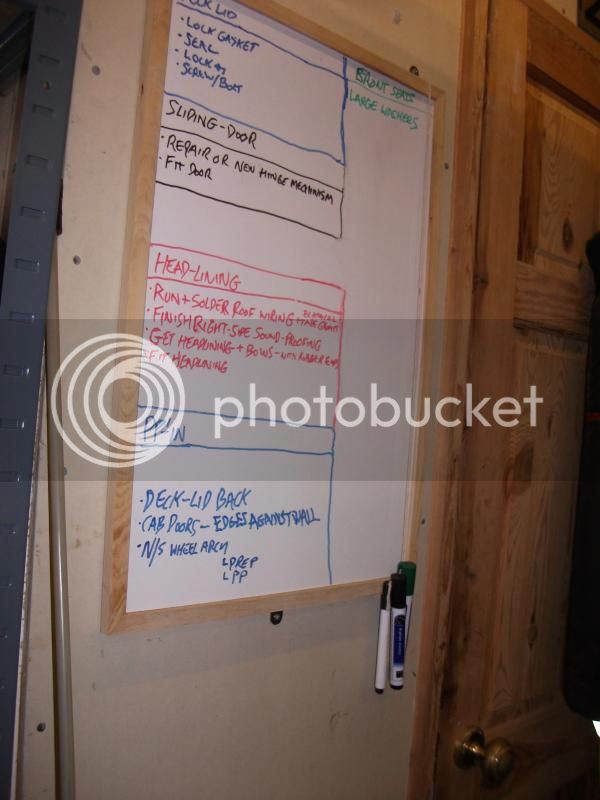

cunning plan

Well-known member

- Joined

- Jul 15, 2008

- Messages

- 2,625

- Reaction score

- 1

- Location

- Northamptonshire

- Year of Your Van(s)

- 1968

- Van Type

- Clipper / Microbus

Cleaned up the inside of the right cab-door before fitting properly with new fixings.

Not too worried about over-paint in some areas as I would rather have a solid door to paint when I've saved for a proper paint job when the bus is on the road than rust everywhere again.

Got to love fresh fixings.

Put the right cab door quarter light in - WOW, fiddleist job, EVER. :| Not enjoyable at all. looks good though. Just need to tidy up the scraper positioning.

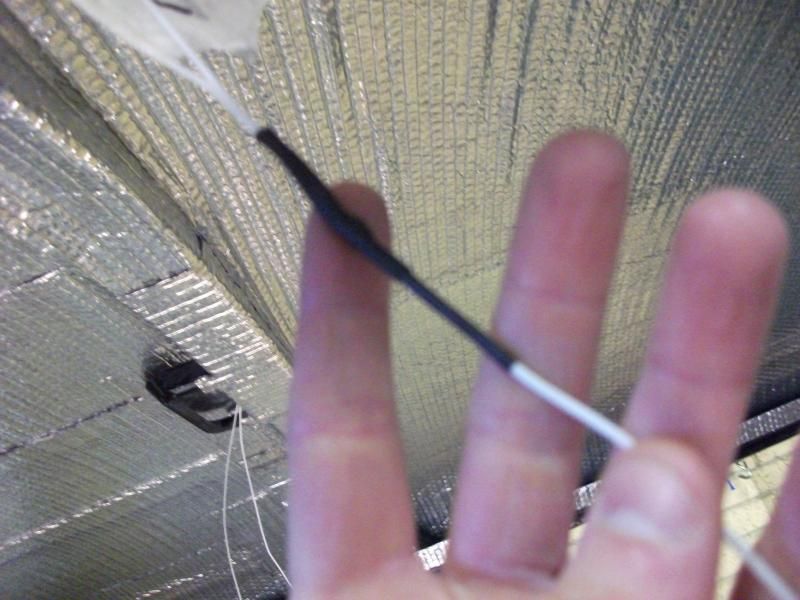

Old wiring loom is out ready for me to use it as a guide to build a new one.

Decided I will run the new loom through some existing holes in the chassis box-section rather than through the chassis legs as it was before as it seems extremely hard to run the wires through without stripping the plastic from them or damaging them in general.

Made up a spacer for the rear hatch alignment wedge to help get the hatch to sit more in the middle.

Works well.

Not too worried about over-paint in some areas as I would rather have a solid door to paint when I've saved for a proper paint job when the bus is on the road than rust everywhere again.

Got to love fresh fixings.

Put the right cab door quarter light in - WOW, fiddleist job, EVER. :| Not enjoyable at all. looks good though. Just need to tidy up the scraper positioning.

Old wiring loom is out ready for me to use it as a guide to build a new one.

Decided I will run the new loom through some existing holes in the chassis box-section rather than through the chassis legs as it was before as it seems extremely hard to run the wires through without stripping the plastic from them or damaging them in general.

Made up a spacer for the rear hatch alignment wedge to help get the hatch to sit more in the middle.

Works well.