Commercial Phil

Well-known member

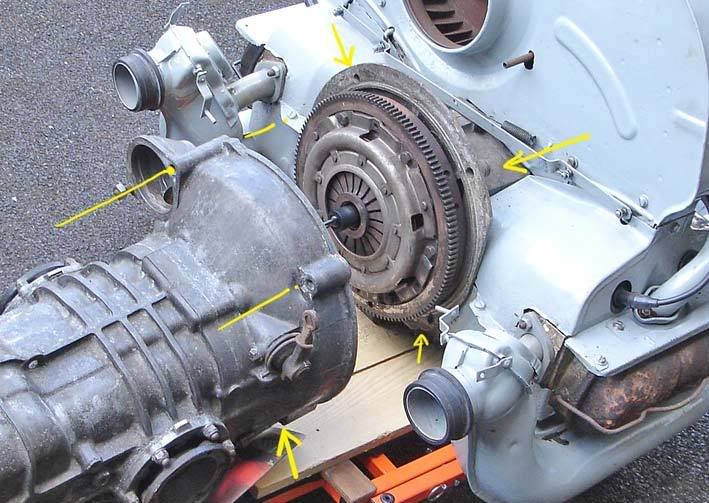

Just started stripping down the back of my van do remove the engine :?

Got to sort out release bearing noise as i think it's shifted due to catching the floor now the vans lower :roll:

It's a 70 and i've removed the bumper and rear engine valance bit... The guide to keeping your aircooled alive book then say's to undo the four bolts on the support brace (just after the exshaust). i seem to have about six bolts in total 4 in the centre.

Was going to support the engine with a block of wood and jack on the sump plug area but would i be better off draining the oil and then removing the brace? Book says to drain oil after removing brace but can't see a sensible place to support the engine :?

Any hints or tips guess it's easy once you've popped your cherry Don't fancy getting it wrong

Don't fancy getting it wrong

Cheers

Phil

Got to sort out release bearing noise as i think it's shifted due to catching the floor now the vans lower :roll:

It's a 70 and i've removed the bumper and rear engine valance bit... The guide to keeping your aircooled alive book then say's to undo the four bolts on the support brace (just after the exshaust). i seem to have about six bolts in total 4 in the centre.

Was going to support the engine with a block of wood and jack on the sump plug area but would i be better off draining the oil and then removing the brace? Book says to drain oil after removing brace but can't see a sensible place to support the engine :?

Any hints or tips guess it's easy once you've popped your cherry

Cheers

Phil