greg said:

nice but it is better to have the cooler in a certain angle cause mounted like you did it isn't gonna have any airflow threw it.

gretz greg

cheers greg,will take a look if theres a better alternative

Today i have concentrated on finishing the exhaust manifold,the slip joints that are standard are a pain to seal properly and on an early bay the engine bar gets in the way of the exhaust clamps,my solution was to fit the exhaust,mark where the slip joints would actually fit and put a spot of weld on them,i then cut the j tubes in half at a convenient point to get the exhaust off the motor.

I fully welded the slip joint and made some flanges to join the j tubes back together (using a standard exhaust gasket for a total seal) i then painted it black with woodburning stove paint

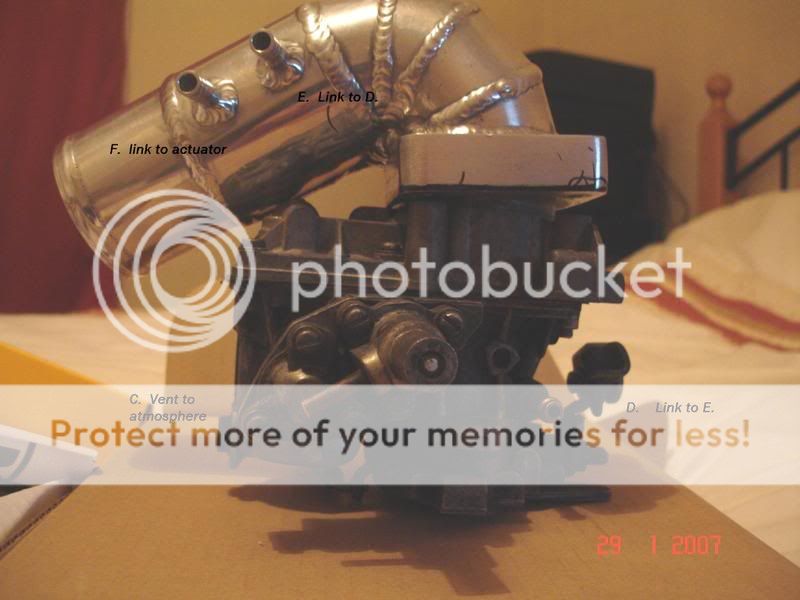

I did a bit more reading about blow off valves (dump valves) and as they are connected to a vacuum line i needed to insert a barb fitting below the carb butterfly (in the inlet manifold) a quick look through the trusty fittings box got me a 90 degree fitting that i welded in on the rear of the manifold,i have tried to put all the fittings bar one at the back to keep things neat and tidy,i hate seeing spaghetti wiring and piping.

i refitted it all and installed the carb,i have piped it up as the next photos show,it works so far so cant be that far out

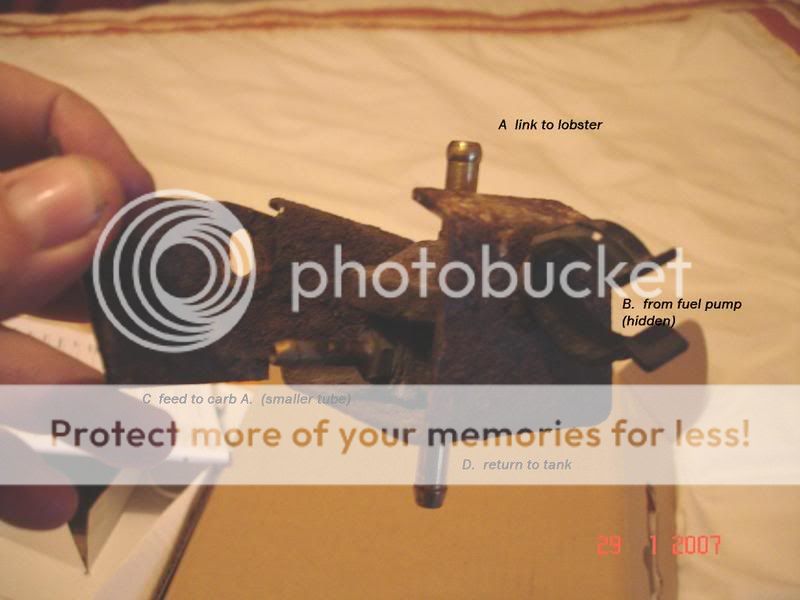

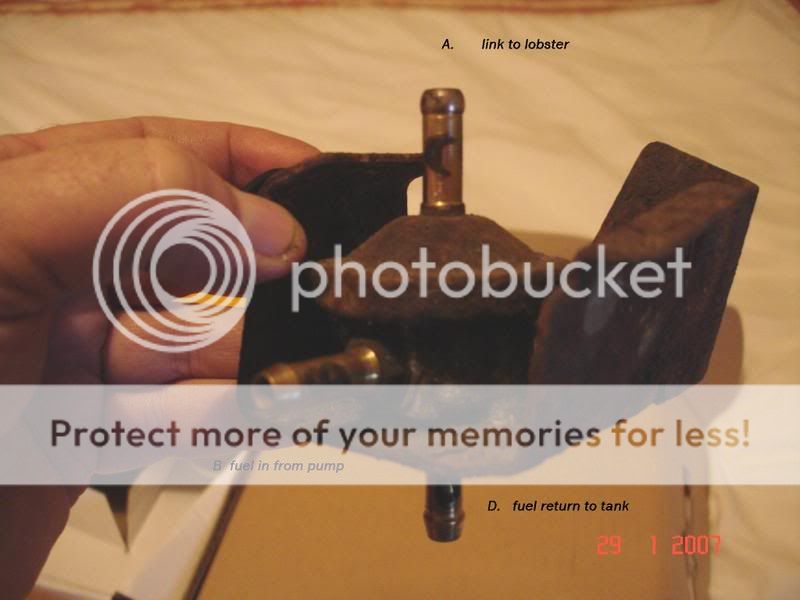

the photos show the old alloy 'lobster' that i was going to use but as i have replicated the fittings on the one i have made it is piped the same,the new fitting i welded into the inlet manifold is connected to the dump valve and a boost guage is tee'd off as well,

i was desperate to get it running so rigged up the fuel pump,after making sure every pipe that carries fuel or will be under pressure has a hose clip on it.

i fitted the oil filter and piped the full flow pipes into it,i have not piped up the cooler as yet as i want the swarf from the bearings etc to be contained in the filter and not in the cooler.

i made sure that everything was tight and filled it with oil,took the plugs out and spun the engine over untill the oil light went out,topped up the oil,refitted the plugs and turned it over,no one was more surprised than me that it started straight up,a bit wooly at first but after a bit of tweaking it idled ok and is not too loud,i am not sure if the drain is working or not yet,there is a small amount of blue smoke when it is revved but as it is a fresh engine i would expect this,if it continues when i eventually drive it i will definitely fit a scavenge pump

here is a video of its first breath,excuse the fat bloke laughing like a mentallist,my mrs thought it would be a good idea to film me as i had dragged her from in front of the fire

still need to wire in the fuel pump and fan properly,still waiting for my proper oil hose clamps to arrive,great isnt it,you can get stuff delivered from china and the states faster than your own back yard