We must not forget the influence the trailing arm has on th wheel travel...

let us consider the vehicle at stock height without a trailing arm. when the wheel travels up, the wheel travels in an arch with the arch length created by the spring plate. the wheel will obviously rotate about the torsion bar which has a linear stiffness. at stock height, as the wheel travels up it will also intially travel backwards until the springplate is horizontal. although only by a small amount, this does change the wheel base between the front and rear wheels. Without the trailing arm, there would be zero camber change as the wheel travel up. an example of this is if you picture the front trailing arms as 1 springplate, when you lower the front of your bus the camber angle remains unchanged.

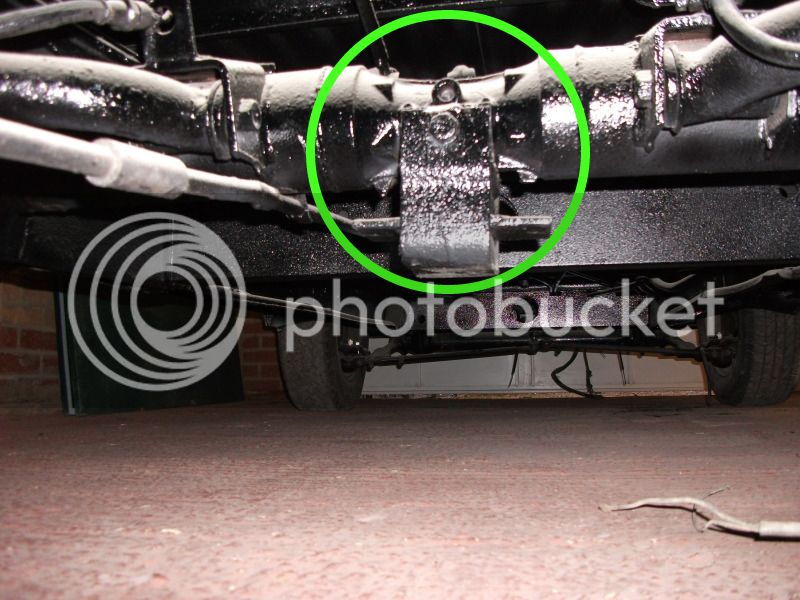

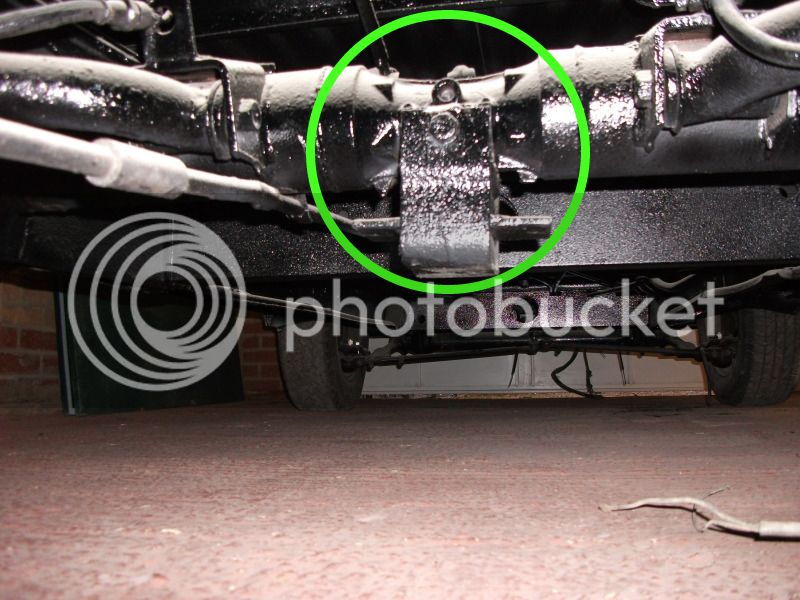

the introduction of the trailing arm provides the camber change with vertical wheel travel. how? well, as we know, the trailing arm is mounted to a cleat on the outside of the torsion tube/chassis by means of a bush. the axis at which the trailing arm rotates is slightly offset from the axis of rotation of the springplate (which is the centerline of the torsion bar). this offset, in rotation means that when the wheel travels the vertical direction, it also travel inboard at a predecribed motion. this is dependent on the position of these axis and the properties of the bushes used in the springplate covers and the trailing arm. if being pedantic, this setup is actually a semi trailing arm. this setup will also provide a level of toe change with vertical wheel travel.

I hope this doesnt confuse you more. if you want me to clarify anything just let me know.

you know notice a level of enthusiasm. This is because i have recently started working at Ford of Australia, modelling/designing suspension systems.

on a personal level i would love to get modelling our campervans to see exactly how good the "original" setup was compared to all the aftermarket suspension mods, from lowered buses, horseshoe plates, adjustable springplates, dropped spindles, coilovers, and the Red9Design wishbone suspension. none of which have actually quantified these "improvements".

NaFe

p.s. Trikky2, not to mention they are generally good over a large weight range similar to leaf springs