You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1970 San Francisco westfalia resto

- Thread starter K@rlos

- Start date

Help Support Early Bay Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

Well it’s been a good summer in the bus and other than a couple little niggles which is to be expected with any new engine the 2276 has performed superbly, fast smooth and surprisingly good on fuel for what it is.

Got 1 more show I’m doing next weekend then it’s gonna be tucked away in my workshop and the gearbox will be off to cogbox for some upgrades

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

dubdubz

Well-known member

looking epic my man - very jealous as mine is squirrelled away and I am taking bits off rather than getting it going...

I also like the water pumper to the right of the pic, thinking of getting one for the wife and getting it sign written for her business...

I also like the water pumper to the right of the pic, thinking of getting one for the wife and getting it sign written for her business...

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

Thanks man, I’ve loved it this year! New engine runs and pulls so nice. Willlooking epic my man - very jealous as mine is squirrelled away and I am taking bits off rather than getting it going...

I also like the water pumper to the right of the pic, thinking of getting one for the wife and getting it sign written for her business...

Be getting some TLC over winter though.

The T5 belongs to my mate Marcus, it’s trick af. On air with a lush interior and banging stereo. They are good vans providing you get a decent 1 (like all things)

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

Brought an auto meter pro-lite (the red 1) ages ago but only just got round to fitting last week. Is wired up as an additional oil pressure light bit more noticeable when I’m on the strip lol. I’ve got a 10psi oil pressure switch, my logic is if anything happened like a cooler or pipe split etc the light would come on before total destruction

$27.95 ($13.98 / Count)

Marketplace Auto Parts Window Crank Handle Set of 2 - Chrome with Black Knob - Compatible with 1968-1978 Volkswagen Beetle

Parts Geek LLC

$22.27

$29.89

ハセガワ Hasegawa HMCC11 1:24 Scale VW Type 2 Pick-Up Truck Model Building Kits

Amazon Japan

$52.99

Tamiya 51616 VW Bus Type 2 (T1) Remote Control Car Accessory Body RC Model Making

Sunset Retail

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

- Joined

- May 17, 2021

- Messages

- 457

- Reaction score

- 392

Amazing venue!

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

It was superb! Klabang camping in Laxfield on the Norfolk/Suffolk borderAmazing venue!

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

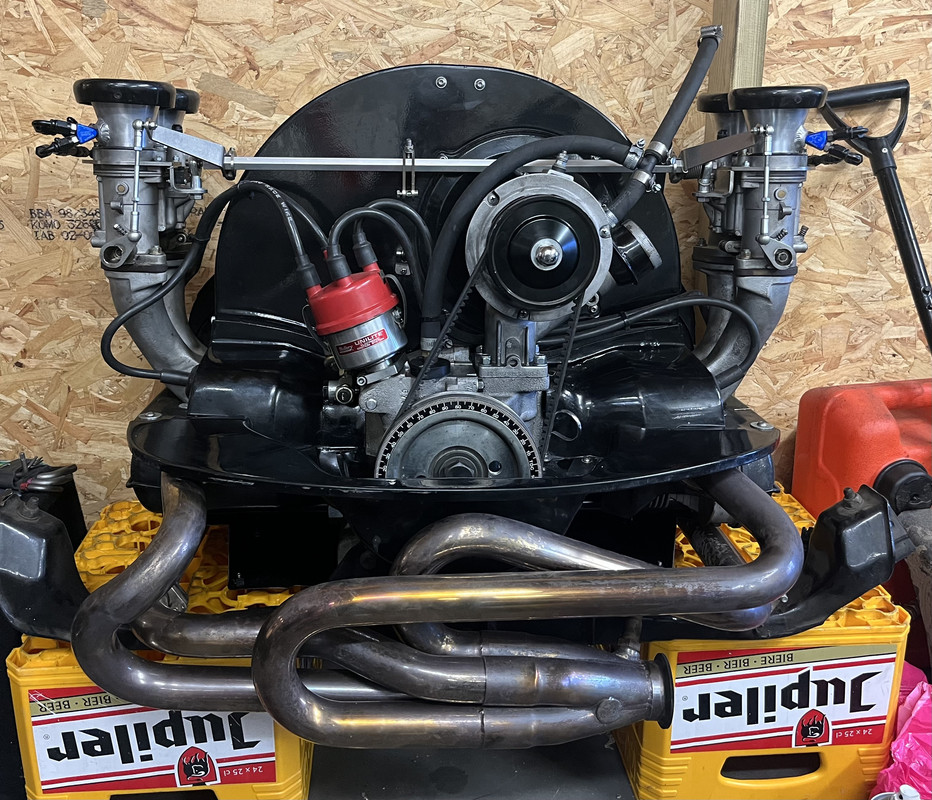

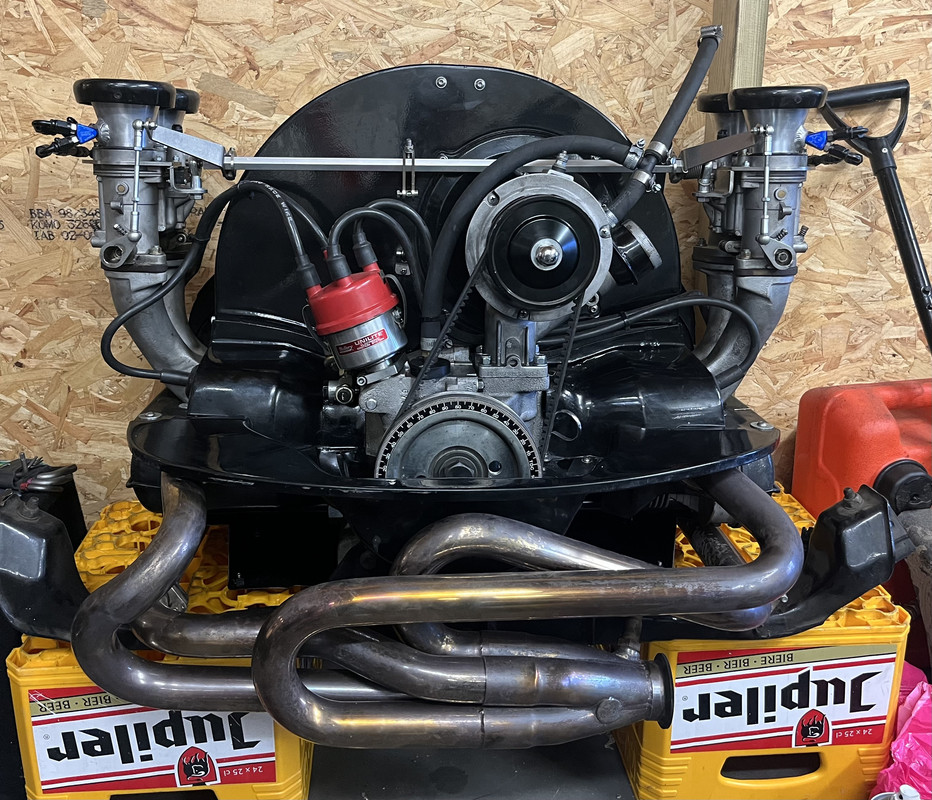

While my 091 gearbox is with Pete at cogbox I went through the 2276. Fresh plugs, cleaned the rotor & cap and checked the valve lash.

image hosting

image hosting

I then made a start on fitting my 2nd line lock switch. The 1 facing forward holds the front brakes and engages the 2-step rev limiter while disabling the wide open throttle switch for the nitrous for launching and the switch facing sideways is just purely the line lock for burnouts.

image hosting

image hostingI then made a start on fitting my 2nd line lock switch. The 1 facing forward holds the front brakes and engages the 2-step rev limiter while disabling the wide open throttle switch for the nitrous for launching and the switch facing sideways is just purely the line lock for burnouts.

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

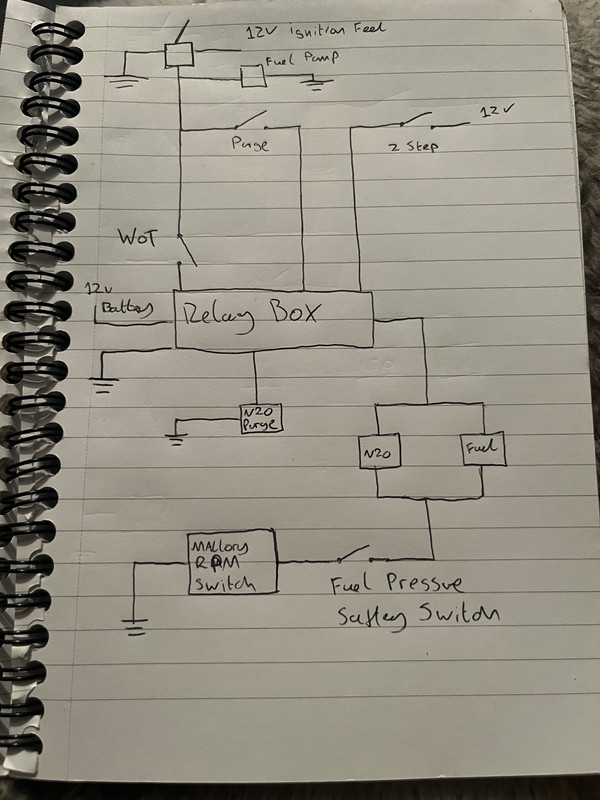

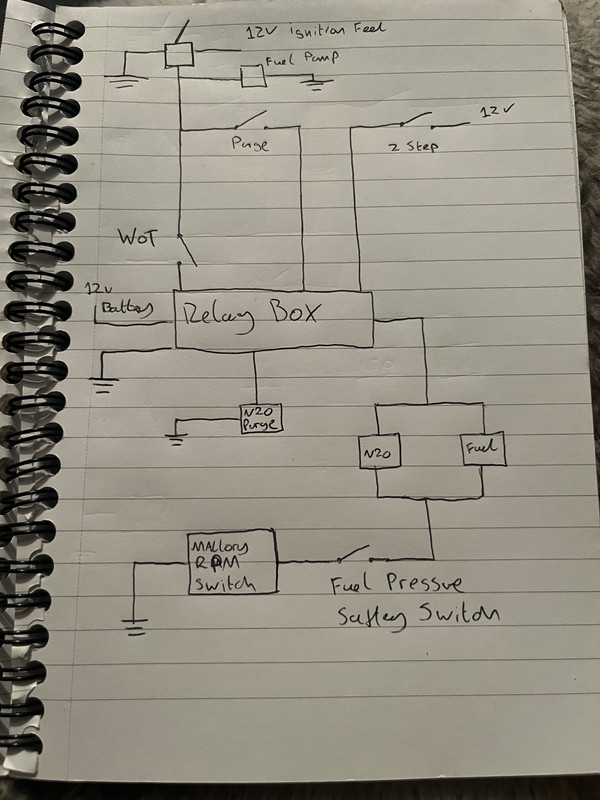

Decided to re do the wiring for the nitrous, it was a quick job and wasn’t that neat, I also found this which is made by a company in the states. Will contain everything in little box so 1 is on the way

I’ve now drawn up (badly) a new wiring diagram to work with with the control box, only need to run 3 wires from the cab to the back end now

a new wiring diagram to work with with the control box, only need to run 3 wires from the cab to the back end now

I’m got everything I can to make it as safe for the engine as possible.

Hobbs fuel pressure safety switch, if the fuel pressure drops below a pre set pressure it kills the entire system, most nitrous failures are due to not enough fuel which results in a blow torch effect.

My Mallory ignition box has an rpm window switch. I can set what RPM range the gas will work in, I’ll go with 3500-7000. This is so if the engine bogs off the line it won’t cause damage

And a ‘Wide open throttle’ switch, this only activates the system when I’ve got it floored, which will protect engine during gear changes, if I let off it shuts down and will help consistency. Basically if it’s floored between 3500-7000 it will be injecting nitrous. So no red button and warp speed effects on the landscape as the fast & furious would like you to believe

I’ve now drawn up (badly)

I’m got everything I can to make it as safe for the engine as possible.

Hobbs fuel pressure safety switch, if the fuel pressure drops below a pre set pressure it kills the entire system, most nitrous failures are due to not enough fuel which results in a blow torch effect.

My Mallory ignition box has an rpm window switch. I can set what RPM range the gas will work in, I’ll go with 3500-7000. This is so if the engine bogs off the line it won’t cause damage

And a ‘Wide open throttle’ switch, this only activates the system when I’ve got it floored, which will protect engine during gear changes, if I let off it shuts down and will help consistency. Basically if it’s floored between 3500-7000 it will be injecting nitrous. So no red button and warp speed effects on the landscape as the fast & furious would like you to believe

Last edited:

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

Progress has slowed a bit as I’ve been busy on customers vws and the postal strike has been an issue, but anyway…

Well I got the engine ready to run, fitted a new clutch cable etc. Spun the engine for oil pressure, primed the carbs and pressed the clutch down to start it and the clutch felt weird. I then remembered that on 1 of the last drives in October, I dipped clutch at a roundabout and there was a clunk then some shuddering. In my excitement and haste to get it running again I had totally forgot about that So engine out again

So engine out again

Looks like the pressure plate has failed

James at Stateside tuning hooked me up and balanced the pressure plate to zero too

Also acquired some Dubshop pressure plate shims from a mate so I can dial in the breakaway torque perfectly. Tedious job to do but is a must for a properly functioning clutch, amazing how many experts don’t do this I normally trim rocker pedestal shims to fit, this will save me ******* about doing that.

I normally trim rocker pedestal shims to fit, this will save me ******* about doing that.

Well I got the engine ready to run, fitted a new clutch cable etc. Spun the engine for oil pressure, primed the carbs and pressed the clutch down to start it and the clutch felt weird. I then remembered that on 1 of the last drives in October, I dipped clutch at a roundabout and there was a clunk then some shuddering. In my excitement and haste to get it running again I had totally forgot about that

Looks like the pressure plate has failed

James at Stateside tuning hooked me up and balanced the pressure plate to zero too

Also acquired some Dubshop pressure plate shims from a mate so I can dial in the breakaway torque perfectly. Tedious job to do but is a must for a properly functioning clutch, amazing how many experts don’t do this

Last edited:

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

K@rlos

Well-known member

- Joined

- Sep 8, 2008

- Messages

- 5,336

- Reaction score

- 1,261

- Location

- Woodbridge, Suffolk

- Year of Your Van(s)

- 1970

- Van Type

- Westfalia pop-top

mcvw

Well-known member

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 0

- Views

- 2K

- Replies

- 7

- Views

- 3K

Vehicle For Sale

Early Bay Deluxe 1971

- Replies

- 5

- Views

- 2K

Vehicle For Sale

Very rare Oslo edition SO69-01 1969 Early Baywindow £12K Ono

- Replies

- 0

- Views

- 1K