:mrgreen: No progress on the van itself as work is kicking my arse at the minute! :shock:

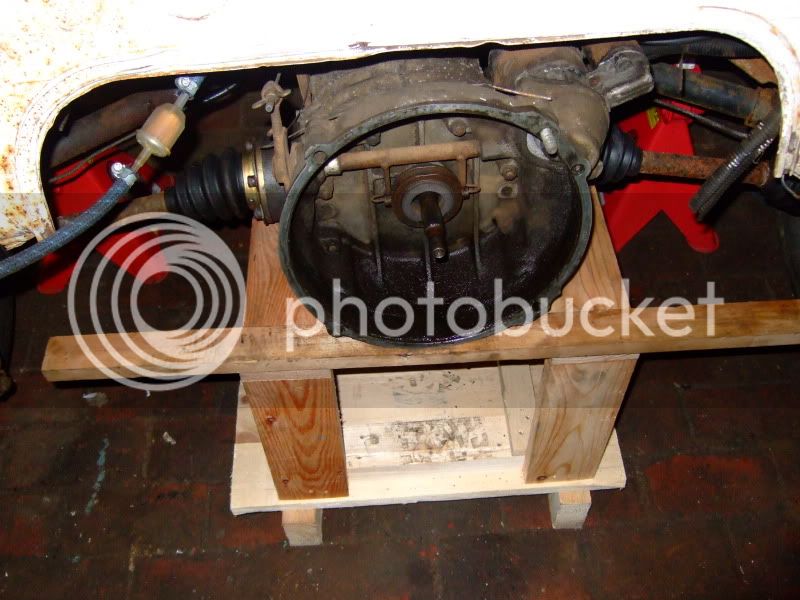

Managed to grab an hour this weekend to start stripping the motor. The plan was to just check it over but man am i glad i tore it down :shock: The decision was made when i noticed the pully was loose but the nut tight, then when taking the flywheel of to get it on the engine stand, the gland nut was about as tight as a $2 hooker!

once stripped it look rough, Not in bad condition just obviously been stood. Scott had told me about this when i bought it.

B&P's look newish but one of the fins had been broken when they where fitted but apart from that and some coking up all look ok. May be changing these anyway but need to see if i can afford a bug bore doo.

As you can see the rods are fairly rusty so a strip down seems to be the right choice so far.

Also bought these from Alfa1750 on fleabay! the man is ace!!

And after askin around about velocity stacks for drla 36's and not finding anything but 40's i though id make my own.

These pics show my first rough drawing and the rings ill be using to create the smooth lip (If you fancy copying these the rings can be bought from a stainlesss fitting stockest and reside under the name 2" female RJT flange. if the price seems abit steep they have quoted for the nut aswell, but thats not needed obviously :mrgreen: )

You get the idea :lol:

Im hoping my design will be a tad more efficent than the standard design which just sits on the top of the carb,filters, linkage plate and gaskets as these will go al the way to the carb eliminating the gap caused by the parts previouly mentioned when using the types that just sit on top.

Hopefully start on these on the moro.