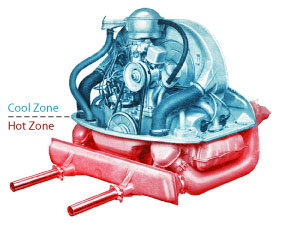

Cheers guys, turn out to be a great journey, purred along at 60 for 200 miles. It's so hot, but awesome.

Sent from my SM-G9600 using Tapatalk

Sent from my SM-G9600 using Tapatalk