I’ve nearly hit the buy button (on reached out to view some) used second hand motors I’ve found. Most have 44mm exhaust and lumpy cams which I’m not interest in. Also would like a stock flywheel.

I’m spending money I don’t even have yet!

Even the VW-Porsche 914's VW Type 4 style, 1970 cm³, 100 hp air-cooled engine, has relatively modest 42 mm inlet & 36 mm exhaust valves.

Apart from that, the largest factory-standard valves used on the VW Type 4 style, air-cooled engine, was

41 mm inlet & 34 mm exhaust valves, for the 1795 cm³ variant with either 68 hp or 85 hp. The 1976~79 VW 2000 Type 2's & 1980~83 VW Transporter T3's 70 hp 1970 cm³, air-cooled engine, actually had 39•3 mm inlet & 33 mm exhaust valves; except for the North American variant with Bosch L-Jetronic fuel injection, which had relatively small 37•5 mm inlet valves.

As many engine tuners will acknowledge, it's not just valve size which is important when trying to improve volumetric efficiency, but inlet & exhaust port configuration, surface finish and minimization of flow resistance, consistent with keeping the atomized fuel in suspension; which typically involves re-profiling the valve-head cross-sections.

Bill Fisher, "How To Hot Rod Volkswagen Engines", HP Books, 1970, ISBN 0-912656-03-4

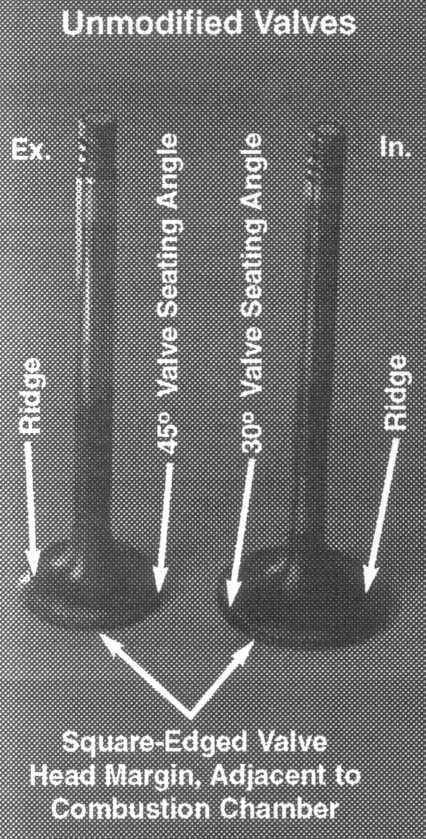

The annotated image below shows used, factory-stock, VW 1800 Type 4, 41 mm inlet & 34 mm exhaust valves.

Note the ridges, around the periphery of the valve seating angles (30º & 45º, for the inlet & exhaust valves respectively), where it adjoins the valve head & valve stem. Note also, the square-edged valve-head margins, which air must flow around, to enter or leave the combustion chamber.

These ridges and square-edged margins, have the effect of creating turbulence, which causes air-flow resistance and reduces the engine's volumetric efficiency.

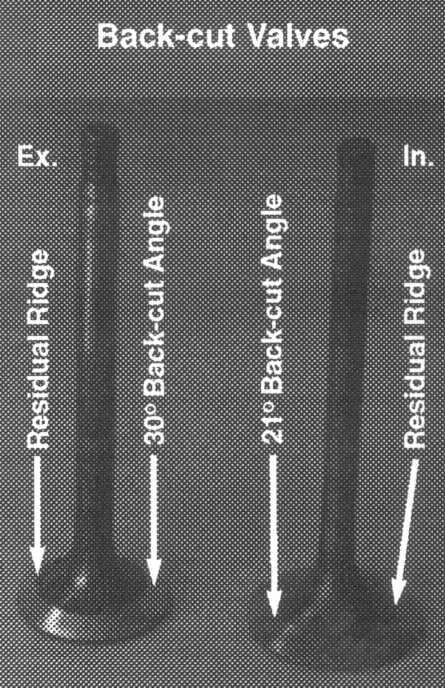

The annotated image below shows used, factory-stock, VW 1800 Type 4, 41 mm inlet & 34 mm exhaust valves, whose valve seating angles (30º & 45º, for the inlet & exhaust valves respectively), have been back-cut (21º & 30º, for the inlet & exhaust valves respectively), to improve air flow.

Note the slight residual ridges, around the periphery of the valve back-cut angles (21º & 30º, for the inlet & exhaust valves respectively), where it adjoins the valve head & valve stem.

Note also, the square-edged valve-head margins, which air must flow around, to enter or leave the combustion chamber.

These residual ridges and square-edged margins, have the effect of creating turbulence, which causes air-flow resistance and reduces the engine's volumetric efficiency.

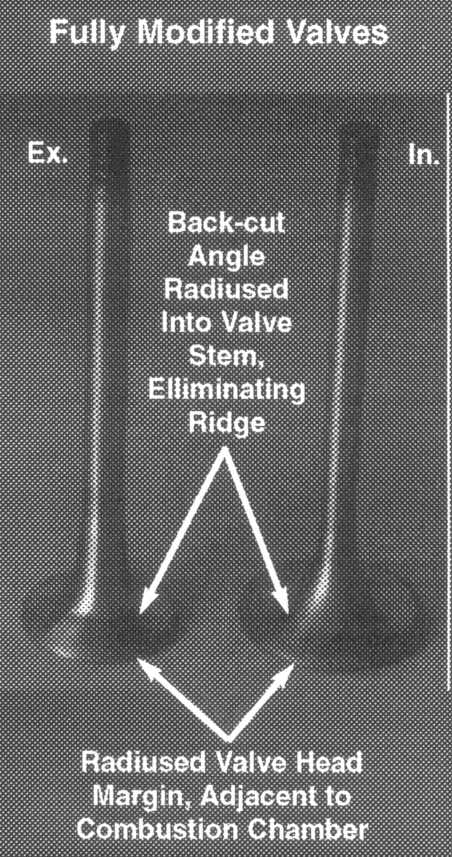

The annotated image below shows new, factory-stock, VW 1800 Type 4, 41 mm inlet & 34 mm exhaust valves, whose valve seating angles (30º & 45º, for the inlet & exhaust valves respectively), have been back-cut (21º & 30º, for the inlet & exhaust valves respectively) using a valve grinder. Using a lathe to rotate the valve about its stem axis, the residual ridge was ground smooth and radiused into the valve stem to improve air flow, using a hand-held grindstone and varying grades of emery cloth.

Note that the formerly square-edged, valve-head margins, have also been similarly radiused using a hand-held grindstone and varying grades of emery cloth, to reduce turbulence when air flows around them, to enter or leave the combustion chamber.