Hello all,

I am looking for a little advise. I am just back from a 1300 mile trip in my 1973 Bay round Ireland starting from Portsmouth.

Had a great time and the van did not let me down. As I am sure you may have recently experienced very hot weather. The midday run back from Wales to Portsmouth was very hot so we plodded along just passing lorries to help the engine.

I would like to drive faster and do in cold weather, so I have started planning a winter project to install an external oil cooler so I can have a little peace of mind.

I have started reading about external oil cooling systems and thought I would drop a message here to find out pitfalls of a particular systems, things to avoid and ask a few questions.

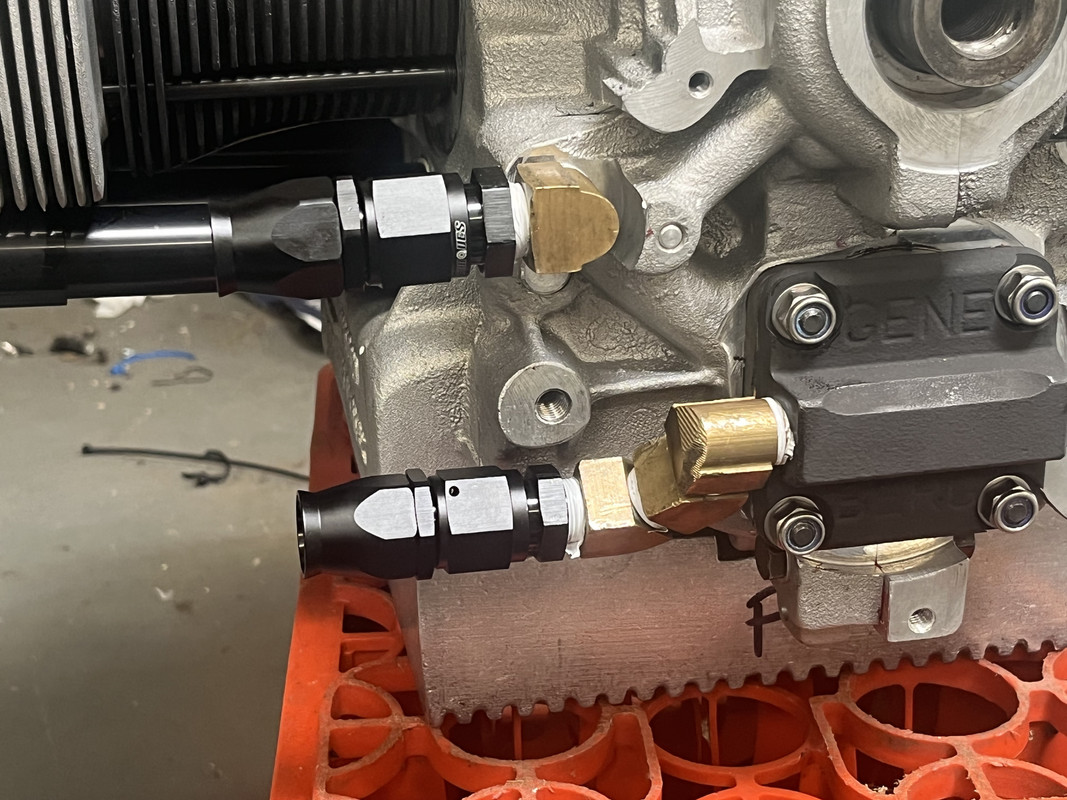

1 - Full flow, can any type1 case be drilled to fit a full flow system? I think I have the blank on mine and I am confident I can drill and tap a hole.

2 - Is full flow better than / worth the hassle compared to a Maxi pump 3?

3 - What is the best location for the oil cooler (with fan and thermostat)?

1973 Bay, Engine 1776 (Engine Shop, fast road cam), duel weber cabs, electric fuel pump, 123 Tune distributor, stupid loud SS Exhaust with J tubes.

When the engine is out I will spend some time "adjusting" the tinware, it could fit better and blow more over the heads. In winter I replace the J tubes with heat exchangers but getting warm air to the front is still work in progress, bloody cables..

Photo of my van on Inch Beach, Ireland. Thanks for reading and any advise.

Mat.

I am looking for a little advise. I am just back from a 1300 mile trip in my 1973 Bay round Ireland starting from Portsmouth.

Had a great time and the van did not let me down. As I am sure you may have recently experienced very hot weather. The midday run back from Wales to Portsmouth was very hot so we plodded along just passing lorries to help the engine.

I would like to drive faster and do in cold weather, so I have started planning a winter project to install an external oil cooler so I can have a little peace of mind.

I have started reading about external oil cooling systems and thought I would drop a message here to find out pitfalls of a particular systems, things to avoid and ask a few questions.

1 - Full flow, can any type1 case be drilled to fit a full flow system? I think I have the blank on mine and I am confident I can drill and tap a hole.

2 - Is full flow better than / worth the hassle compared to a Maxi pump 3?

3 - What is the best location for the oil cooler (with fan and thermostat)?

1973 Bay, Engine 1776 (Engine Shop, fast road cam), duel weber cabs, electric fuel pump, 123 Tune distributor, stupid loud SS Exhaust with J tubes.

When the engine is out I will spend some time "adjusting" the tinware, it could fit better and blow more over the heads. In winter I replace the J tubes with heat exchangers but getting warm air to the front is still work in progress, bloody cables..

Photo of my van on Inch Beach, Ireland. Thanks for reading and any advise.

Mat.