When I was cleaning up the arches I noticed the rear jacking points (edit NOT jacking points, they're fine, I meant to say seatbelt anchors) were not looking too clever and since I'm putting the original bench seats back in I wanted all the seatbelt anchors to be in good order. I also had a few holes to fill from an abandoned heater install and I wanted to build up a level of competence with my welding on the bus before moving on to next main job.

so cut out the old anchors and got on with it. The premade plates are from Schofields that were then extended.

Quite happy with the results and it's all solid

Next job was to tweek the engine support bar. My exhaust J-Tubes were banging on the bar as there was no clearance, not now.

The last image gives a hint of my next welding job.

PURISTS LOOK AWAY NOW!

One of the things I love about the late bay (yes, I said it) is the great access to everything if you had a two litre model. Most of these came with an inspection hatch which I've always hankered after. So I found one from an EB member and got to work.

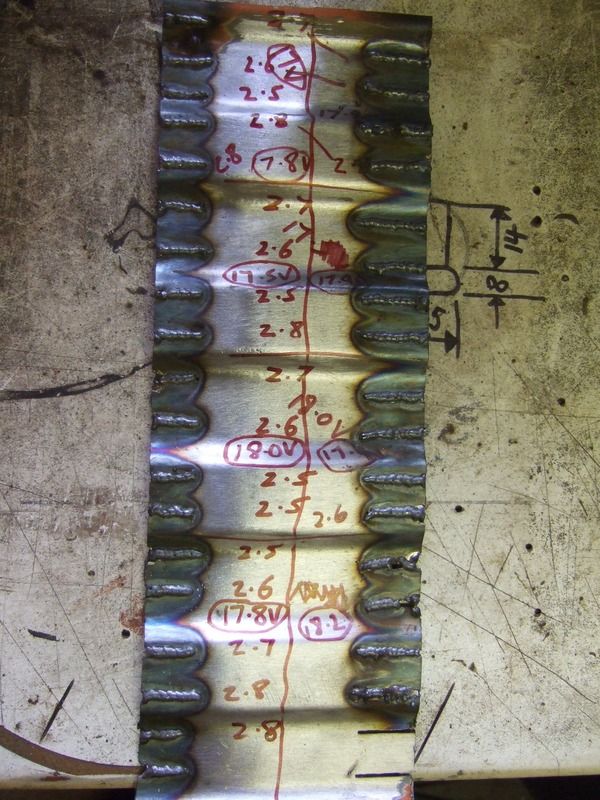

I bought pretty much the whole rear deck including the framework. I drilled out all the spot welds.

I started with 6mm spot weld drills but after taking no time to break two I moved on to 8mm. They are not cheap drill bits and I used cutting fluid too. 8mm is definitely the way to go but does require more work down the line. Perhaps more care and less pressure would have netted a better result. It's all down to experience I guess and I'm new to most of this.

Cut through all the spots

and eventually got the bit I wanted. I've cut it so there is plenty to play with.

Get out!

Started to clean it all up

but couldn't get into some areas...

back to the blasters then?